Tank body internal welding system

A welding system and tank technology, applied in welding equipment, welding accessories, welding rod characteristics, etc., can solve the problems of high technical requirements of welders, difficult to guarantee welding quality, and low welding productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

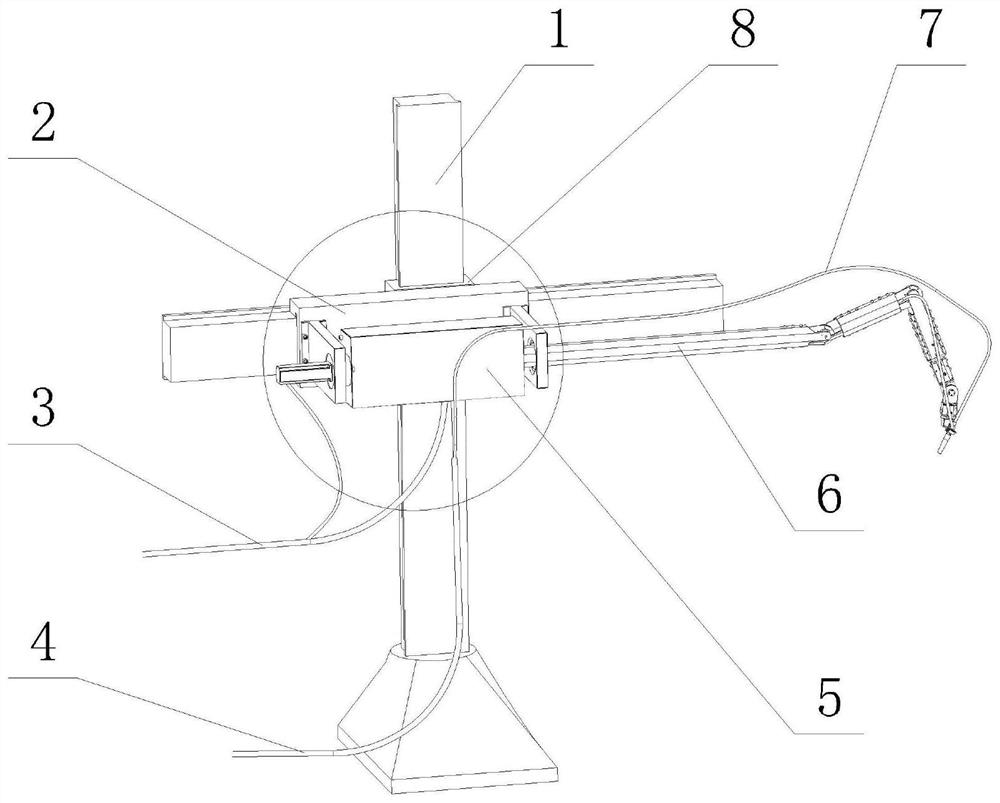

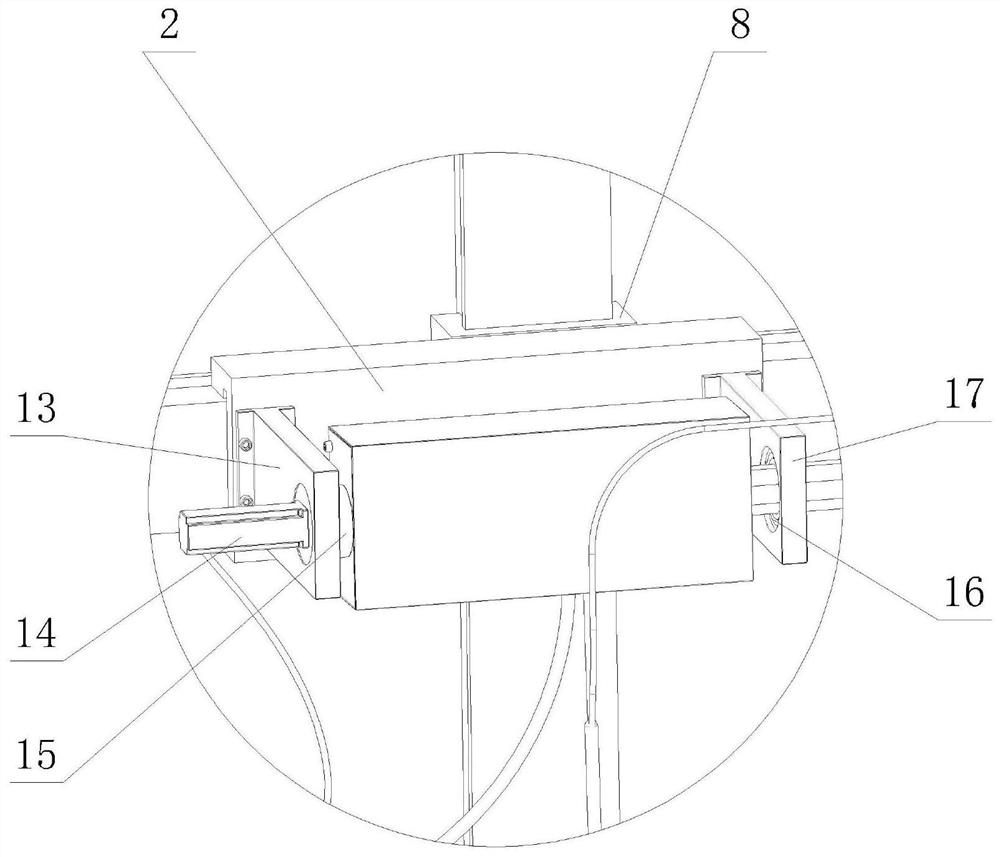

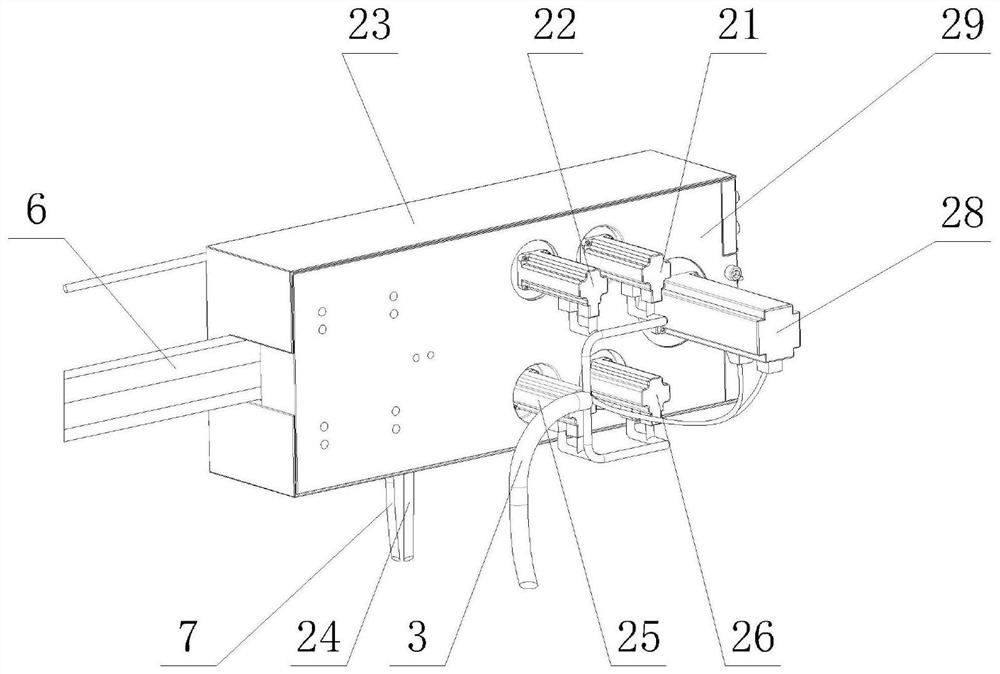

[0027] Specific implementation mode one: combine Figure 1 to Figure 15 Describe this embodiment, including cross movement platform 1, driving device 5, mechanical arm 6, servo cable 3 and welding cable 4, it is characterized in that: described mechanical arm 6 is made up of connecting rod one 60, joint two 61, connecting rod two 62, joint three 63, connecting rod three 64, joint four 65, connecting rod four 66, joint five 67, connecting rod five 68, joint six 69, the cross beam slider 2 is installed on the cross motion platform 1, the The left support 13 of the mechanical arm and the right support 17 of the mechanical arm are installed on the beam slider 2, the left support 13 of the mechanical arm is equipped with a joint-harmonic speed reducer 15, and the drive unit 5 is composed of a drive unit base 29, a drive unit The protective case 23 and 5 sets of power output systems are composed, the drive device base 29 is equipped with a left mechanical arm fixing clip 32 and a ri...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination Figure 1 to Figure 15 Describe this embodiment, joint two 61 of this embodiment is composed of joint two cross roller bearing 90, joint two driven wheel 95, joint three steel wire rope guide wheel 94, joint four steel wire rope guide wheel one 92, joint five steel wire rope guide wheel One 91, joint six steel wire rope guide wire wheel one 93, connecting rod one bearing mounting flange 82, connecting rod two bearing mounting flange one 87, the connecting rod one bearing mounting flange 82 is installed on the connecting rod one 60, The joint two cross roller bearing 90 is installed on the connecting rod first bearing mounting flange 82, the connecting rod two bearing mounting flange one 87 is installed on the inner ring of the joint two cross roller bearing 90, and the connecting rod two Bearing mounting flange 1 87 is installed on connecting rod 2 62, said connecting rod 2 bearing mounting flange 1 87 is fixedly equipped wi...

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 1 to Figure 15 Describe this embodiment, the driving mechanism of joint two 61 in this embodiment is composed of joint two servo motor 28, joint two harmonic reducer 40, joint two driving wheel 41, joint two driven wheel 95, and joint two servo motor 28 Installed on the rear side of the driving device base 29, the output shaft of the second joint servo motor 28 passes through the driving device base 29 and is fixedly connected to the input shaft of the joint second harmonic reducer 40, and the joint second driving wheel 41 is fixedly installed on the joint second harmonic On the output shaft of reducer 40.

[0034] The driving mechanism of the joint three 63 is composed of the joint three servo motor 26, the joint three harmonic reducer 44, the joint three driving wheel 43, the transmission wheel group one 49, the joint three steel wire rope guide wheel 94, and the joint three driven wheel 108. The transmission wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com