Production and processing technology of TPU high-low temperature film

A high and low temperature film and processing technology, applied in thin material handling, packaging, transportation and packaging, etc., can solve the problems of hanging material, high and low temperature film not reaching the expected quality, overlapping, missing corners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0049] like Figure 1-10 shown:

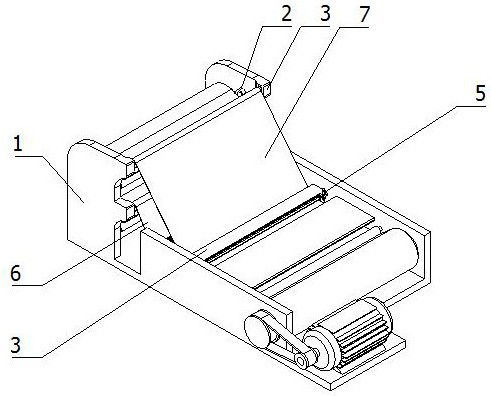

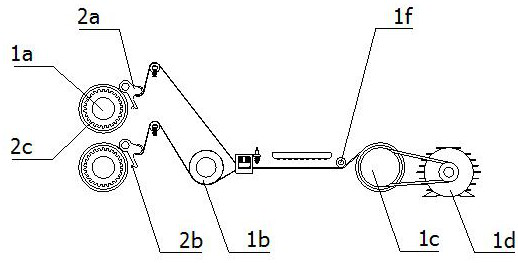

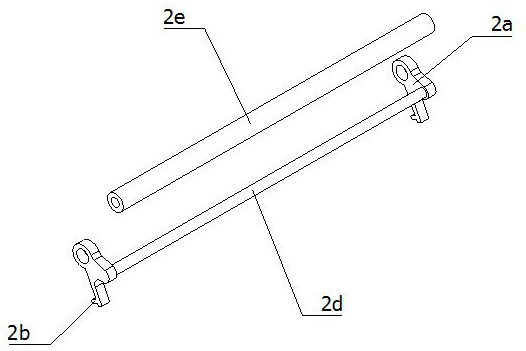

[0050]A production and processing technology of TPU high and low temperature film, the production and processing technology of TPU high and low temperature film is performed by production and processing equipment of TPU high and low temperature film, and the production and processing equipment of TPU high and low temperature film comprises rack 1 and self-locking device 2, rack 1 includes a feeding drum 1a, a glue roller 1b, a receiving drum 1c and a rotary drive assembly 1d. There are two feeding drums 1a, and the two feeding drums 1a are rotatably installed on the frame 1. The glue roller 1b and the receiving cylinder 1c are rotatably installed on the frame 1, the rotary drive asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com