Manufacturing process of aldehyde-free light luxury recombined decorative veneer/material

A technology for reorganizing decoration and manufacturing process, which is applied in the field of wood processing, which can solve the problems of complicated manufacturing process and unenvironmental protection of formaldehyde release, and achieve the effect of no formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

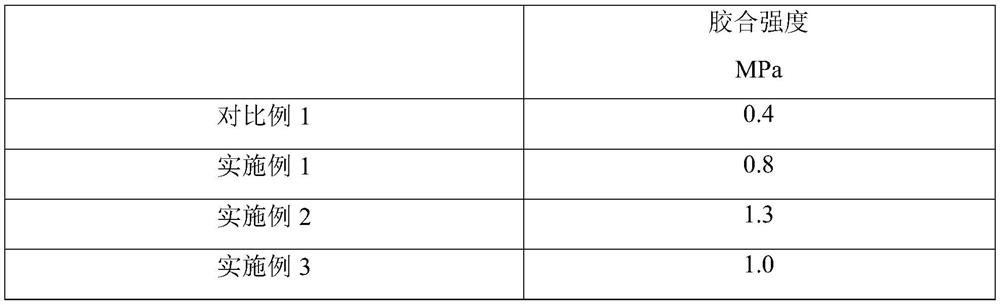

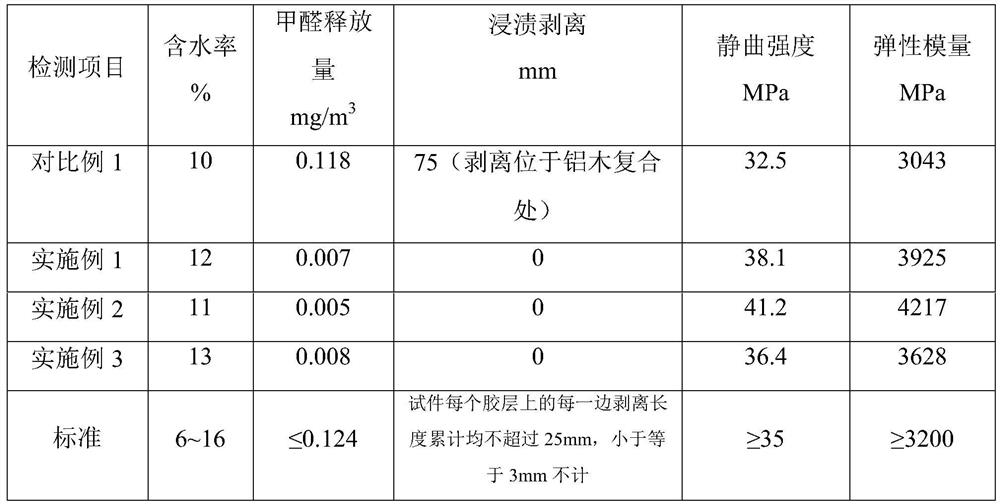

Embodiment 1

[0041] S1: Choose oak, slice the oak into veneers with a thickness of 0.65 mm, and the texture of the veneer is pattern.

[0042] S2: Bleaching the veneer, the bleaching solution consists of hydrogen peroxide with a concentration of 35%, the dosage is 8%, the bleaching aid sodium silicate, the dosage is 0.5%, the bleaching and penetration aid octanol polyoxyethylene ether, the dosage is 0.02 % composition, and adjust the pH to 9-12 with 30% sodium hydroxide solution, and control the bleaching temperature at 50°C;

[0043] S3: Dip dye the dried bleached oak veneer at a dyeing temperature of 95°C until the color of the veneer is consistent with the standard sample.

[0044] S4: Dry the dyed veneer, control the moisture content to 8%, and repair it to remove defects such as wormholes, knots, and discoloration.

[0045] S5: Perform plasma activation treatment on a 0.5mm thick pure aluminum plate at a voltage of 100V, spray methyl acrylate monomer onto the surface of the aluminum pl...

Embodiment 2

[0050] The part with the change of embodiment 1 is as follows:

[0051] S5: Perform plasma activation treatment on a 0.5mm thick pure aluminum plate at a voltage of 100V, spray methyl acrylate monomer onto the surface of the aluminum plate by plasma spraying, and control the spraying time for 10 minutes.

[0052] S6: Put the activated pure aluminum plate in the middle, place a piece of dried single-sided coated water-based one-component polyurethane adhesive (solid content 50%, viscosity 900mPa·s) dyeing veneer on the upper and lower sides, cloth The amount of glue is 160g / m 2 , recombined to obtain a metal veneer layer. The recombination process is hot pressing with a pressure of 0.7MPa, a heating temperature of 100°C, a pressurization time of 6 minutes, and one day of health preservation. For the metal veneer layer, test the bonding strength according to GB / T 17657-2013 "Test methods for physical and chemical properties of wood-based panels and veneered wood-based panels"....

Embodiment 3

[0055] The part with the change of embodiment 1 is as follows:

[0056] S5: Perform plasma activation treatment on a 0.5mm thick pure aluminum plate at a voltage of 100V, spray methyl acrylate monomer onto the surface of the aluminum plate by plasma spraying, and control the spraying time for 15 minutes.

[0057] S6: Put the pure aluminum plate after activation treatment in the middle, place a piece of dyed veneer with acrylic emulsion (solid content 60%, viscosity 600mPa s) on one side after drying, and the glue amount is 140g / m2 2 , recombined to obtain a metal veneer layer. The recombination process is hot pressing with a pressure of 0.6MPa, a heating temperature of 80°C, a pressurization time of 5 minutes, and one day of health preservation. For the metal veneer layer, test the bonding strength according to GB / T 17657-2013 "Test methods for physical and chemical properties of wood-based panels and veneered wood-based panels". Assembling several metal veneer layers and ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com