A kind of non-burning cigarette and using method thereof

A technology of cigarettes and shredded tobacco, which is applied in the field of non-burning cigarettes, can solve the problems of not being able to impart flavor to tobacco, volatilization of chemical components of pods, and no feeling of smoking, so as to achieve the effect of enriching smoking methods and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a tobacco coating liquid is provided, comprising the steps:

[0028] S1.2012 Hunan Xiangxi Middle Orange Three (A) red-cured tobacco leaves, rolled into cylindrical tobacco bundles (length 84mm, diameter 7.8mm);

[0029] S2. Use a smoking machine to smoke the smoke bundle, control the suction speed to be uniform (35mL / puffs (2s)) and minimize the smoldering of the smoke bundle, collect the particulate matter of mainstream smoke through the Cambridge filter, Condensing and recovering the gas phase of the mainstream flue gas at -60 °C; collecting the particulate matter;

[0030] S3. Mix the collected gas-phase condensate and the granular material, and apply the mixture as a coating solution on the paper base with a coating amount of 5-15%; after drying, a carrier coated with the tobacco extract is obtained.

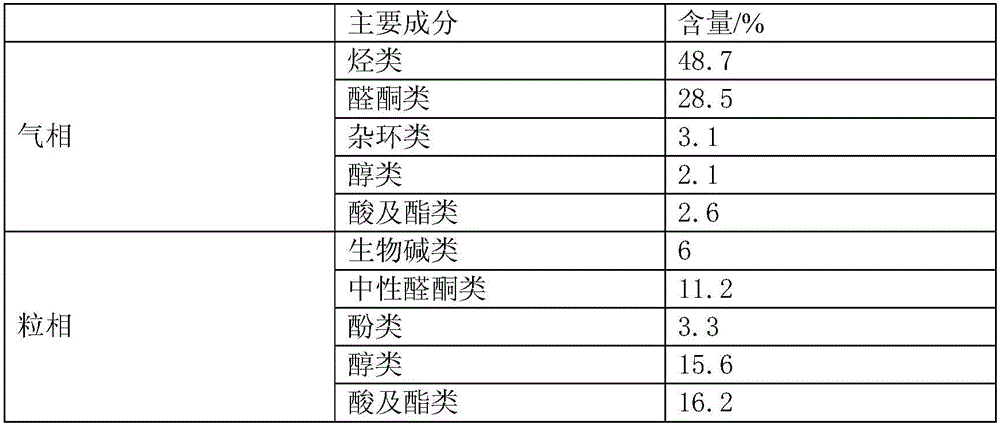

[0031] The components of the prepared mixture of gas-phase condensate and particulate matter are detected. The main components are as follow...

Embodiment 2

[0041] The non-burning cigarette in Example 2 includes a filter tip and a cut tobacco segment, and the filter tip refers to an existing conventional hollow structure, and the cut tobacco segment is a shell, a heating material layer and a carrier coated with tobacco extract from outside to inside, The tobacco extract is the tobacco extract commonly used in the field, and the tobacco coating solution prepared in Example 1 can also be referred to. The carrier is a conventional reconstituted paper base for cigarettes.

[0042] The casing is made of cigarette paper.

[0043] The heating material layer, in parts by weight, includes 20 parts of iron powder, 15 parts of water, 15 parts of activated carbon, 5 parts of vermiculite, 3 parts of sodium chloride and 3 parts of natural mineral powder.

[0044] The use method of the present invention is that before smoking the cigarette, rubbing the cut tobacco section for 30 seconds, the heating material layer gradually releases heat due to...

Embodiment 3

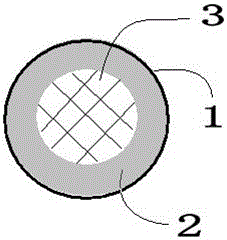

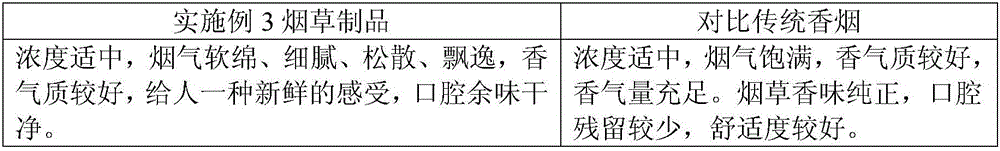

[0047] as attached figure 1 As shown, the non-burning cigarette in Example 3 includes a filter tip and a cut tobacco segment. The cut tobacco segment is an outer shell, a heating material layer and a carrier coated with tobacco extract from the outside to the inside, and the filter tip is a hollow structure.

[0048] The housing is made of stainless steel.

[0049] The heating material layer, in parts by weight, includes 12 parts of iron powder, 10 parts of water, 8 parts of activated carbon, 16 parts of vermiculite, 10 parts of sodium chloride and 10 parts of natural mineral powder.

[0050] The shell and the heat-generating material layer are of the same length and longer than the carrier, so that the carrier will not be ignited when the ignition is used for baking.

[0051] The carrier is a reconstituted paper base for cigarettes.

[0052] The preparation method of described tobacco extract is as follows:

[0053] S1.2012 Hunan Xiangxi Middle Orange Three (A) red-cured tob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com