Air outlet method for realizing a front-blade-free automobile air conditioner

An automotive air conditioner and blade technology, which is applied in the field of auto parts, can solve the problems of occupying more space, occupying car space, unsimple front blades, etc., and achieves the effect of preventing flow obstruction and increasing air flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

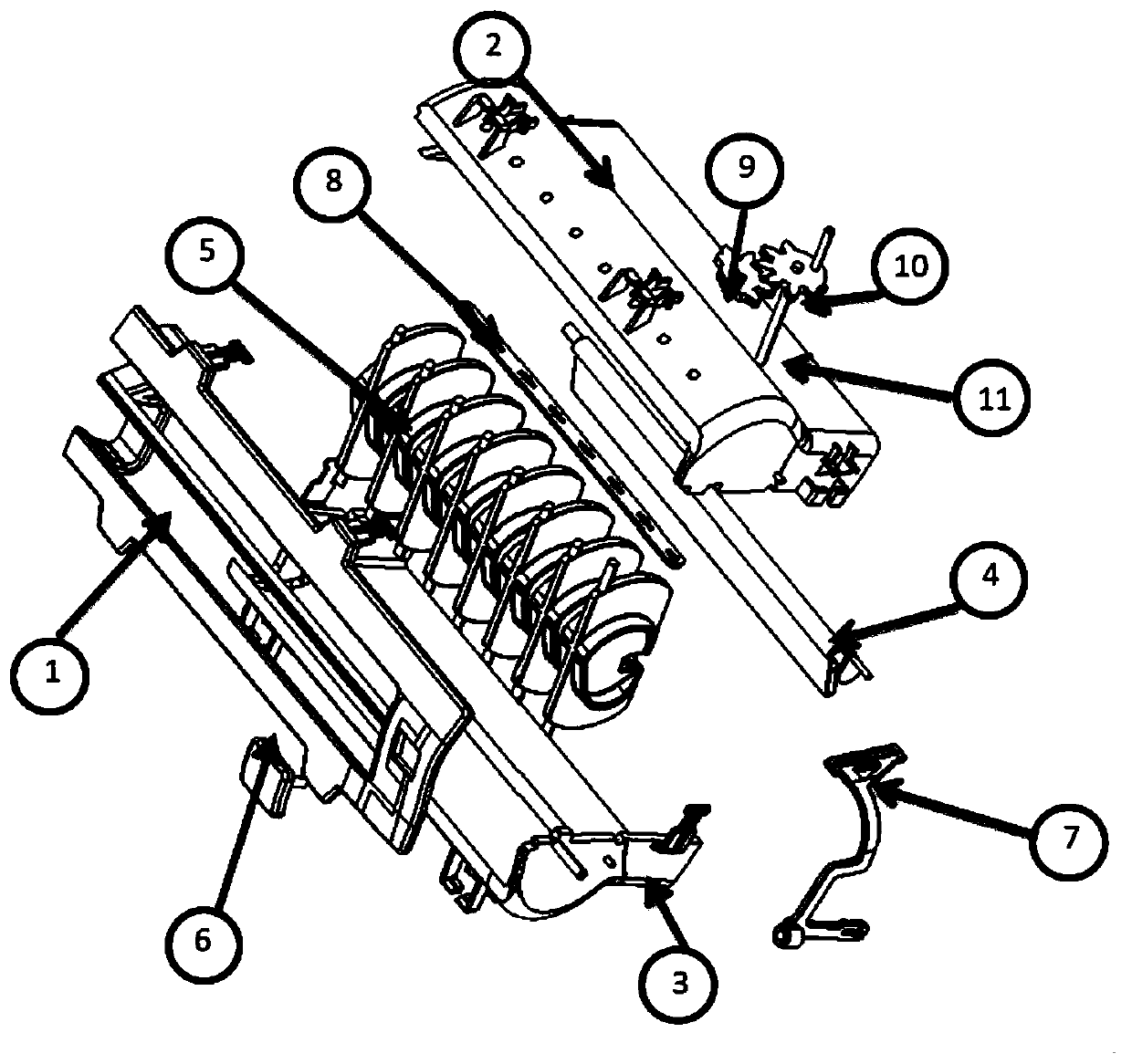

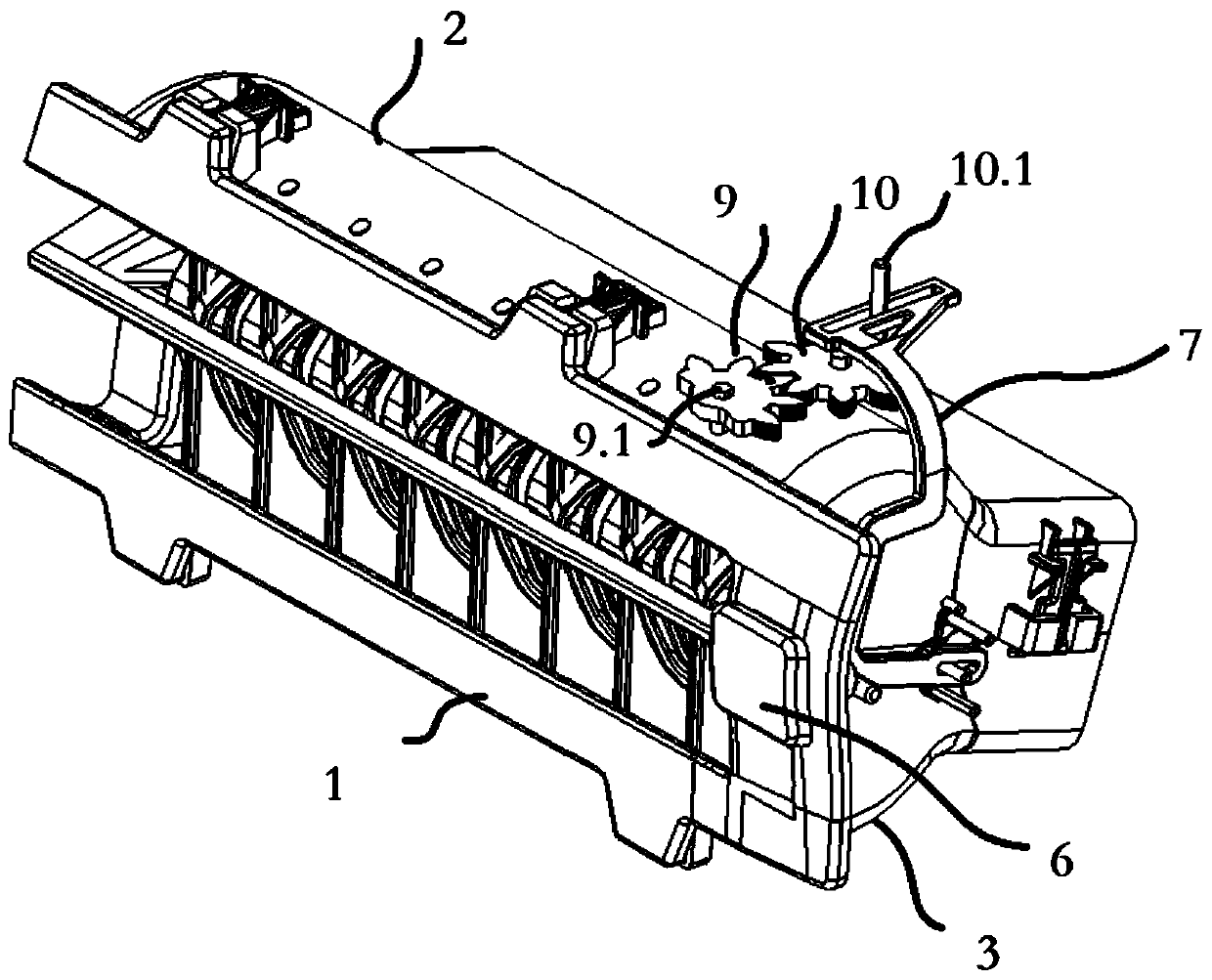

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

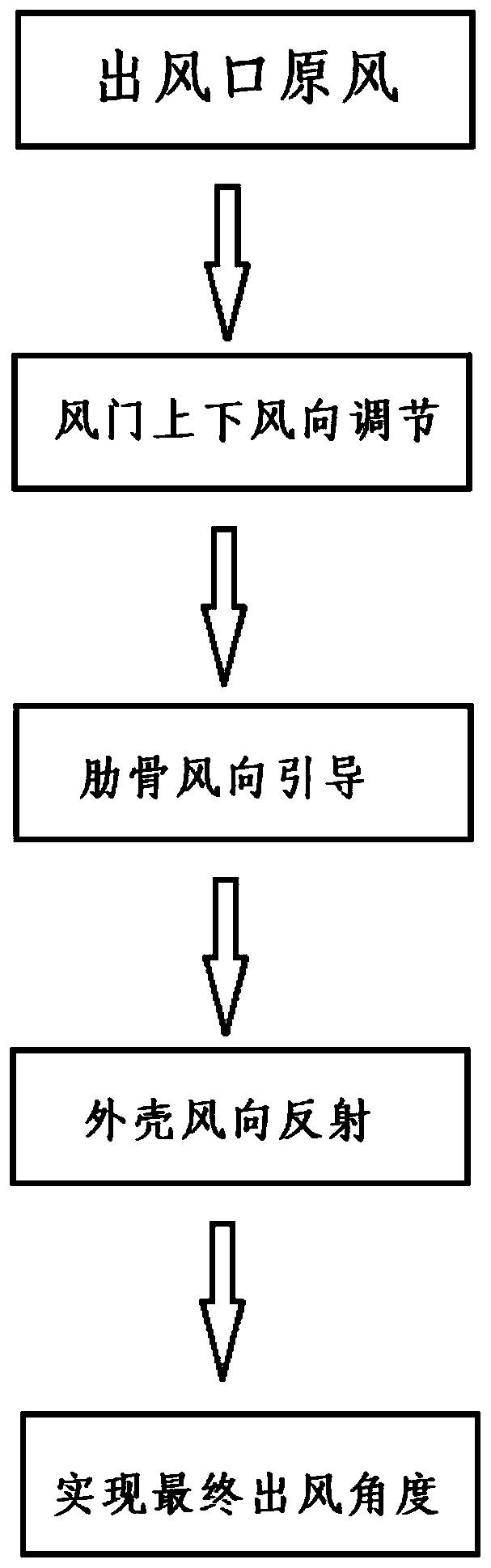

[0038] Such as figure 1 Shown, a kind of air outlet method that realizes automobile air conditioner without front blade, described air outlet method realization process is as follows:

[0039] 1) The original wind at the air outlet passes through the damper to realize the first adjustment of the wind direction, and the damper realizes the adjustment of the upward or downward wind direction of the original wind;

[0040] 2) After the adjusted wind direction, when passing through the rib structure, guide the wind direction to the edge of the shell;

[0041] 3) The guided wind direction flows to the inner side of the arc-shaped or circular shell, and the final air outlet angle of the wind direction is realized through the reflection of the wind direction after blowing to the shell;

[0042] By setting the rib structure and damper guidance on the rear blade group, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com