A prestressed steel strand anchoring device

A technology of prestressed steel strands and anchoring devices, which is applied in the direction of buildings, building reinforcements, building components, etc. It can solve the problems of small unsuitable construction conditions, affecting the appearance of buildings, construction difficulty and high risk factor, and achieves safety and is easier to guarantee , The power transmission path is obvious, and the effect of avoiding high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention. It should be noted that the following "first" and "second" are used for descriptive purposes only, and should not be understood as indicating or implying relative importance or implicitly indicating the quantity of indicated technical features. Thus, a feature defined as "first" or "second" may explicitly or implicitly include one or more of these features.

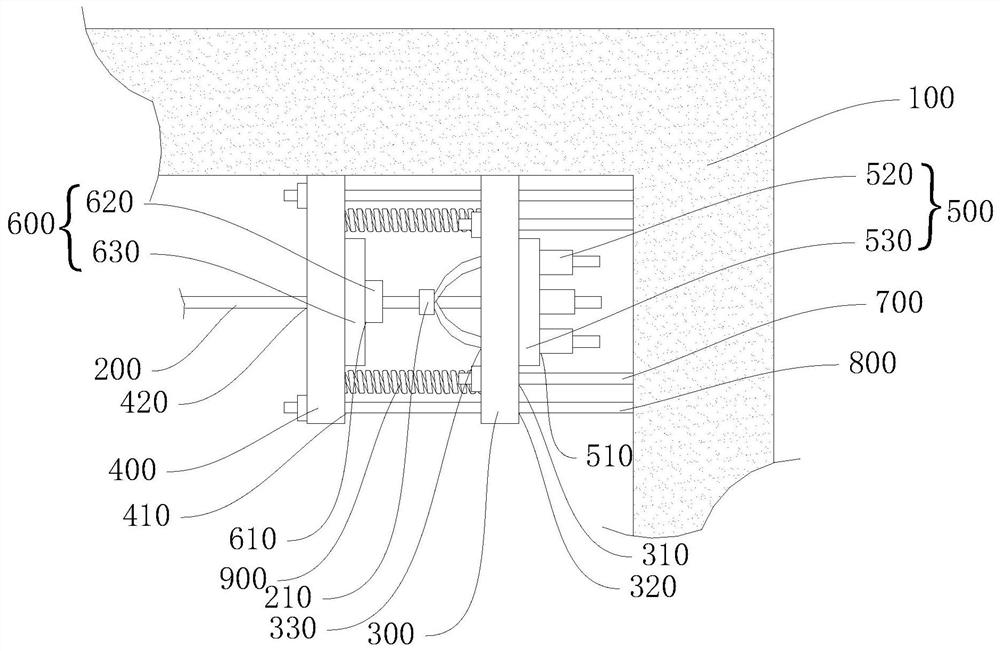

[0018] combined with figure 1 As shown, a prestressed steel strand anchoring device includes a fixed wall 100, a prestressed steel strand 200, a first steel plate 300, a second steel plate 400, a first anchor 500, a second anchor 600, a first high-strength The bolt 700 and the second high-strength bolt 800, the first steel plate 300 and the second steel plate 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com