Bottom form support system and construction method for cast-in-place beams of high-pile wharf

A high-piled wharf and support system technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as large bending moments in the mid-span of longitudinal beams and collapse of bottom formwork support systems, and achieves convenient operation and easy guarantee of safety , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

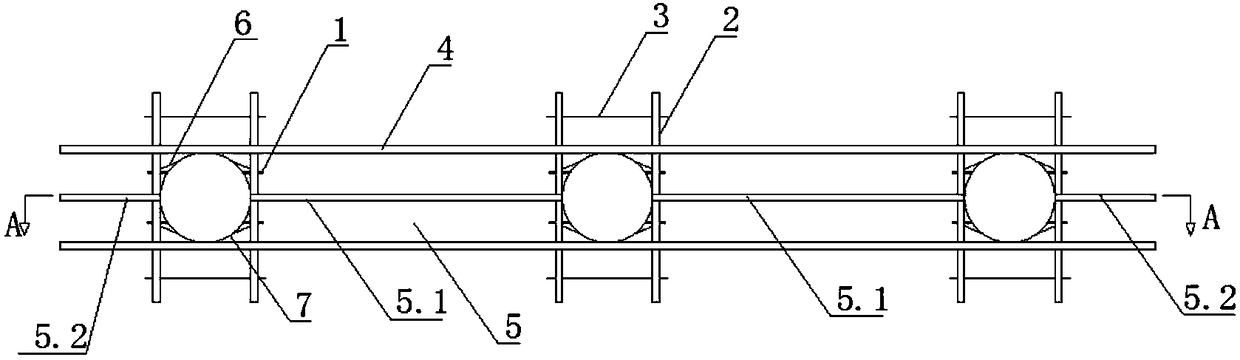

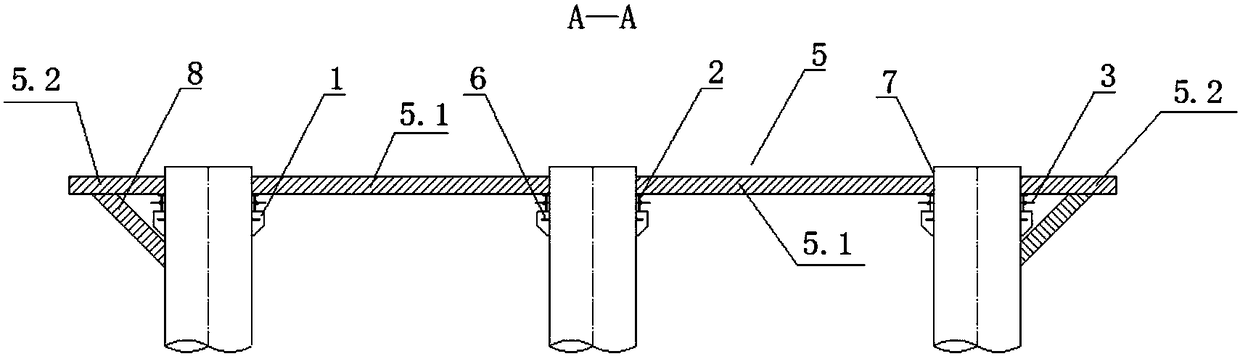

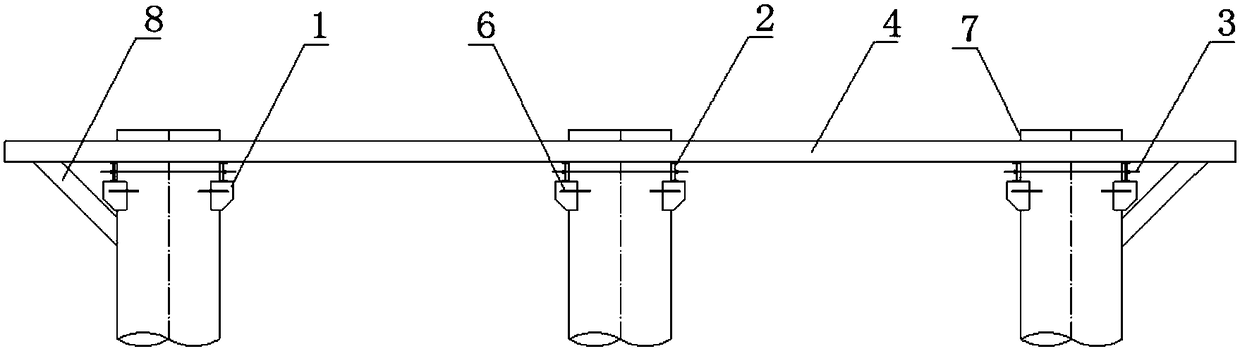

[0025] Such as figure 1 The bottom mold support system of the cast-in-place beam of the high-piled wharf shown in —5 includes a plurality of steel casings 7 arranged on the surface of the cast-in-situ pile along the axial direction of the single-row pile foundation, and the circumferential surface of the steel casing 7 is fixed with multiple A supporting corbel 1 parallel to the axial direction of the single-row pile foundation, and a shelving beam 2 perpendicular to the axial direction of the single-row pile foundation is respectively placed on the supporting corbels 1 located on the front and rear sides of the steel casing 7, and the steel casing 7 The left and right sides of 7 are respectively provided with side beams 4 placed on the shelving beam 2 and parallel to the axial direction of the single-row pile foundation.

[0026] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com