A differential pressure type rapid inflation valve special for plasma rupture protection

A plasma, differential pressure technology, applied in the direction of valve, valve device, functional valve type, etc. for inflation, which can solve problems such as damage, large escape current, strong mechanical stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

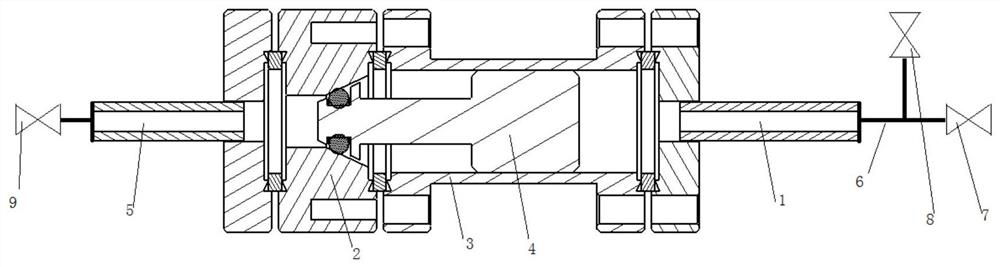

[0015] Such as figure 1 As shown, a differential pressure fast inflation valve dedicated to plasma rupture protection includes an inlet flange 1, a sealing cone 2, a high-pressure chamber 3, a valve core 4 and an air outlet flange 5, and the sealing cone 2 One end of the high pressure chamber 3 is sealed and fixedly connected, the other end of the high pressure chamber 3 is sealed and fixedly connected with the inlet flange 1, the other end of the sealing cone 2 is sealed and fixedly connected with the outlet flange 5, and the inlet flange 1. The high-pressure chamber 3, the sealing cone 2 and the air outlet flange 5 form a working chamber together. The valve core 4 is installed in the working chamber. One end of the valve core 4 is a conical structure, and the other end is a cylindrical structure. , a thin cylindrical rod is connected between the conical structure and the cylindrical structure, and a tapered groove matching the conical structure of the valve core 4 is opened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com