Auxiliary device for installation of vibrating wire strain gauge

An auxiliary device and strain gauge technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement, etc., can solve the problems of being affected by the location of steel bars, complicated operations, etc., and achieve the effect of improving the survival rate and accurately controlling the installation angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

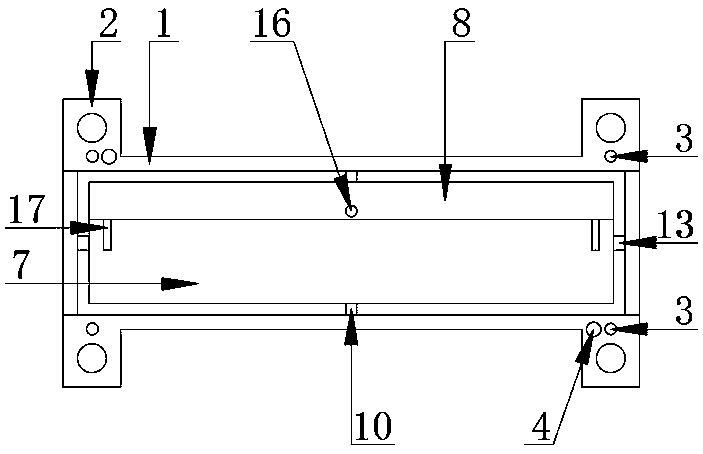

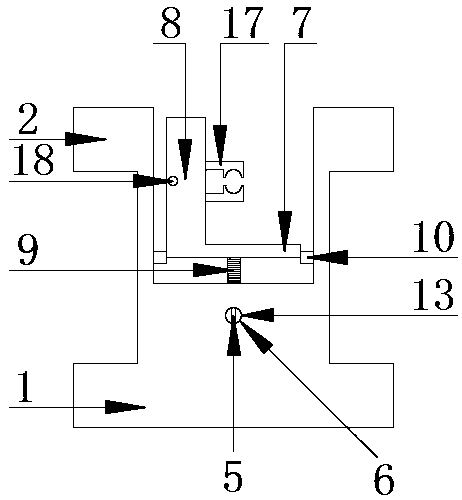

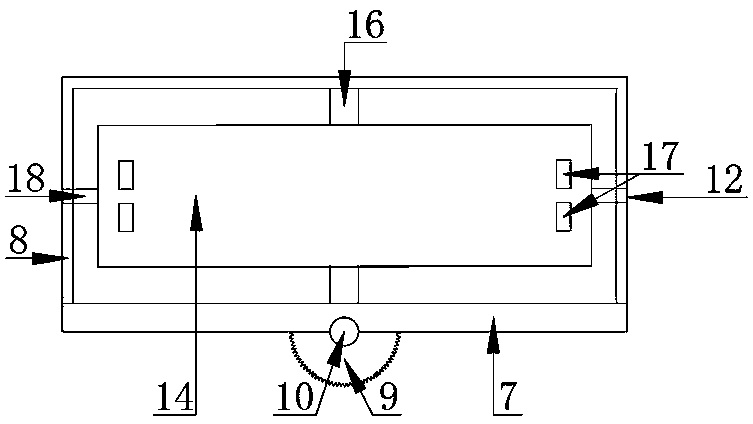

[0025] Such as Figure 1-5 As shown, the auxiliary device for the installation of the vibrating wire strain gauge in this embodiment includes a concrete shell 1, and a groove is provided in the middle of the concrete shell, and the inclination adjustment device in the horizontal direction and the vertical angle adjustment device are used in the groove. The inclination adjustment device is equipped with a vibrating wire strain gauge support 17, lugs are respectively provided at the upper and lower corners of the concrete shell, positioning holes 2 are arranged inside the lugs, and a positioning chip 3 and a level 4 are provided on the concrete shell.

[0026] In the auxiliary device for the installation of vibrating wire strain gauges in this embodiment, the horizontal inclination adjustment device includes a rotating plate A 7, a worm wheel A 9, a rotating pin shaft A 10 and an adjusting rod A 13, and the rotating plate A 7 is installed in the groove of the concrete shell 1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com