Electric kettle

An electric kettle and kettle body technology, applied in the direction of boiling water appliances, etc., can solve the problems of affecting the shape design of the electric kettle, monotonous switch setting position, affecting the use experience, etc., to speed up assembly efficiency, reduce settings, and achieve random changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

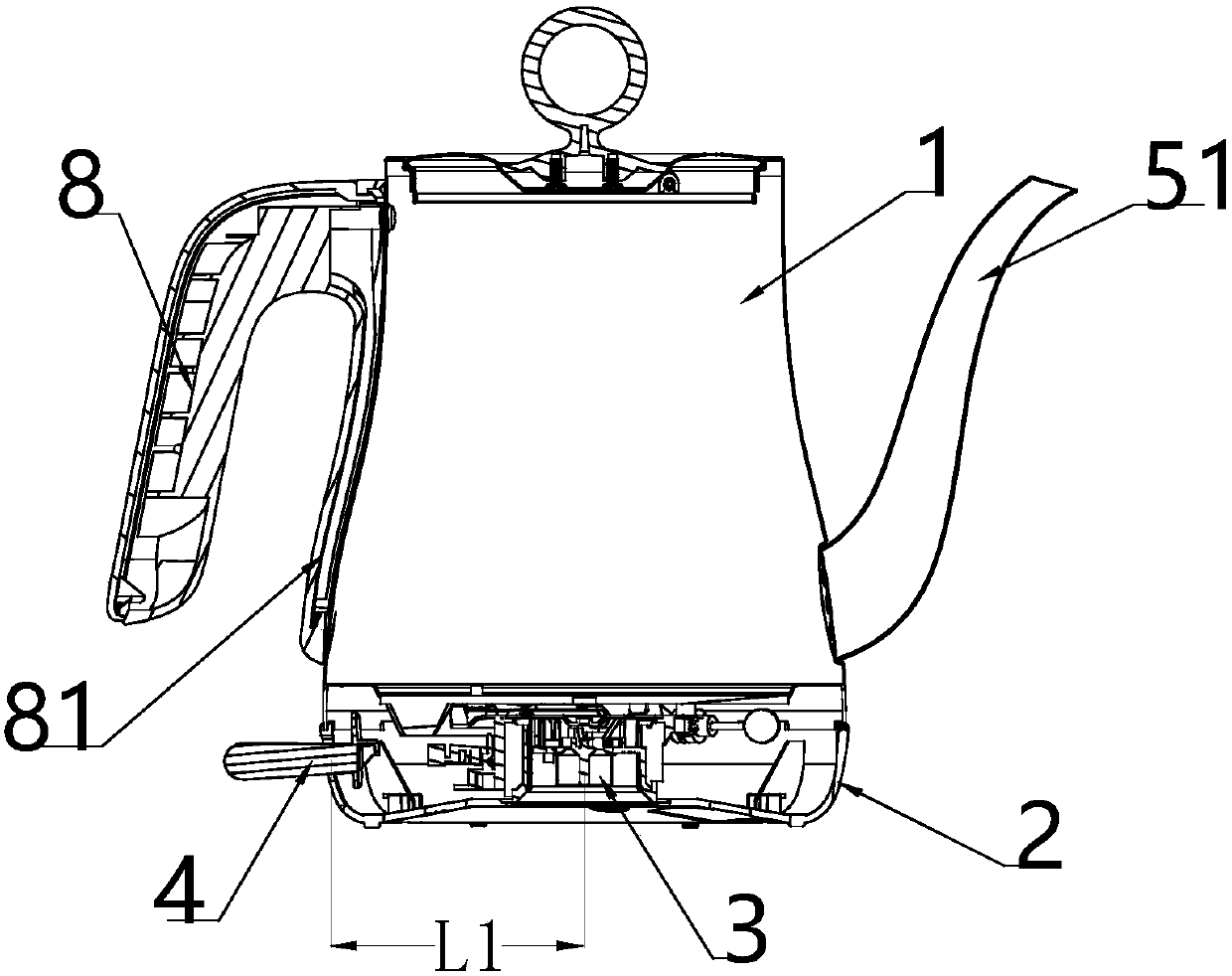

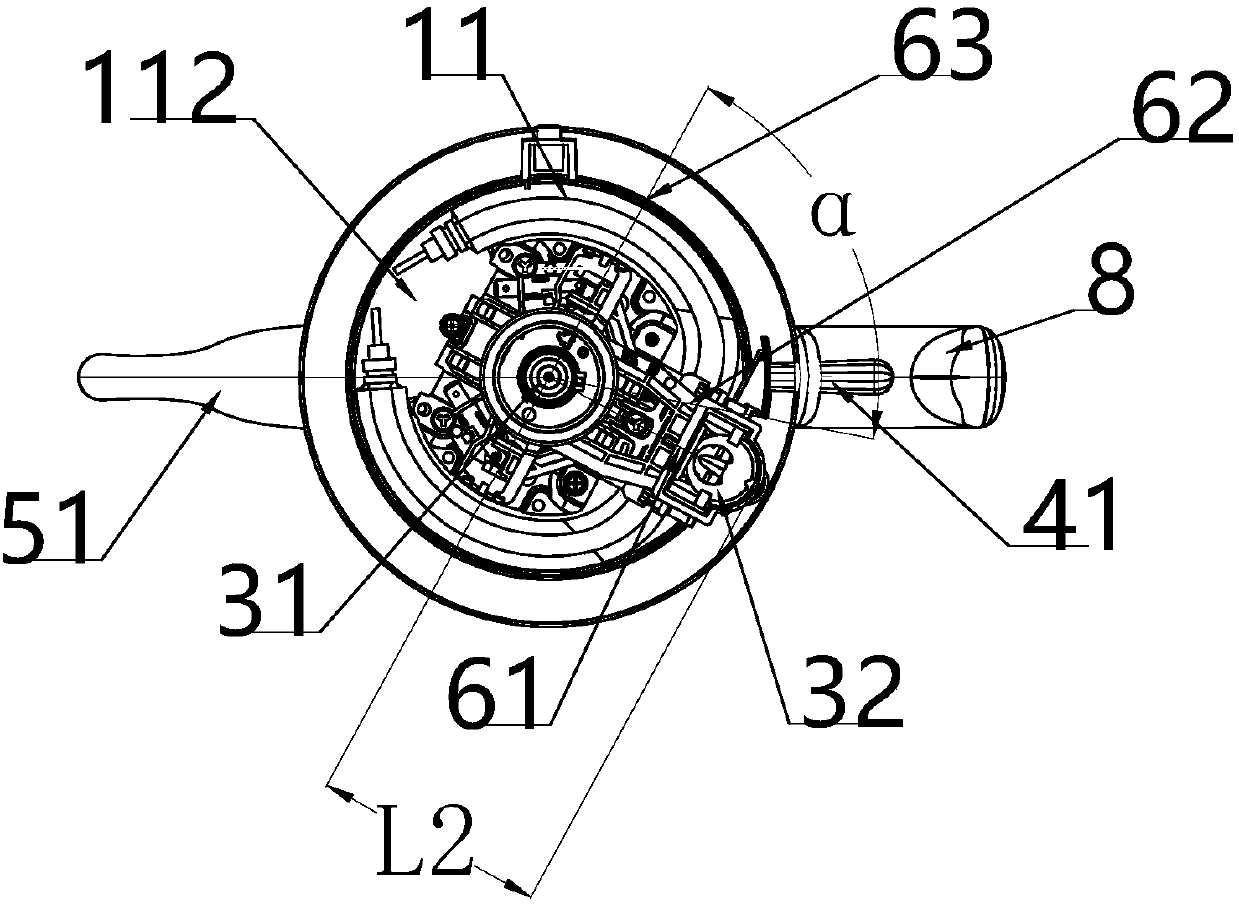

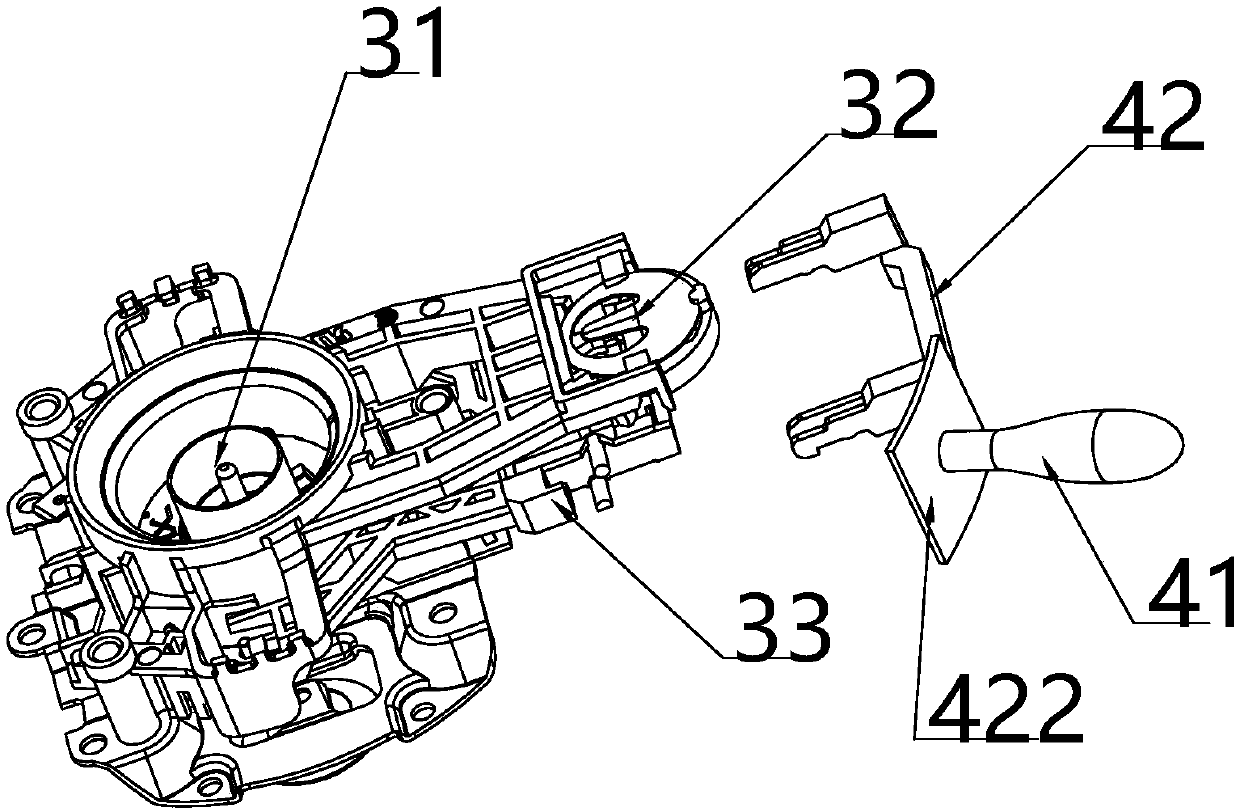

[0033] This embodiment provides an electric kettle, such as figure 1 , 2 As shown, it includes a kettle body and a power base (not shown), the kettle body includes an inner tank 1 and a bottom cover 2 arranged below the inner tank 1, and an installation is formed between the bottom cover 2 and the inner tank 1 chamber, the installation chamber is provided with a thermostat 3 and a switch assembly 4 connected to the thermostat 3, the thermostat 3 includes a housing, an upper coupler 31 and a The steam sheet 32 communicated with the steam pipe 10, the above steam sheet 32 refers to a bimetallic brake, the switch assembly 4 includes a switch bracket 42 and a switch button 41, the switch assembly 4 of the existing electric kettle is generally along the steam sheet 32 The direction of the extension is installed, that is, the switch button is facing the position of the steam sheet 41, and the position where the switch button 41 is set is provided with an opening, and the steam ...

Embodiment 2

[0039] This embodiment provides an electric kettle, such as figure 1 , 2As shown, it includes a kettle body and a power supply base (not shown), and the kettle body includes an inner tank 1 and a bottom cover 2 arranged below the inner tank 1 , forming a gap between the bottom cover 2 and the inner tank 1 The installation chamber is provided with a thermostat 3 and a switch assembly 4 connected to the thermostat 3 in the installation chamber, and the thermostat 3 includes a housing and an upper coupler 31 arranged on the housing And the steam piece 32 that communicates with the steam pipe 10, the above-mentioned steam piece 32 refers to a bimetallic brake, the switch assembly 4 includes a switch bracket 42 and a switch button 41, the switch assembly 4 of the existing electric kettle is generally along the steam sheet 32 for installation, that is, the switch button 41 is facing the position of the steam sheet 41, and the switch bracket 42 moves up and down in the installation ...

Embodiment 3

[0043] Based on the structure of the second embodiment, the kettle body also includes a handle 8, the handle 8 includes a handle and a handle seat 81, the switch button 41 passes through the opening at the bottom of the handle seat 81, and the downward extension of the handle seat 81 can increase the installation space , however, the radial distance from the center of the upper coupler 31 to the opening at the bottom of the handle seat is L3, L3-L2≤10mm, at this time, it is still necessary to carry out avoidance design, and the position of the switch button 41 is relative to the position of the switch button 41 through the switch bracket 42 The position of the steam sheet 32 is shifted, and the switch bracket 42 is also moved inward, so that the distance between the switch bracket 42 and the inner wall of the heating plate and the bottom cover (or the inner wall of the shell) is kept, and the movable space is ensured, so that the switch assembly 4 Able to exercise normally. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com