Fabricated pulling ring overwater drilling platform and building method

A drilling platform and assembled technology, which is applied to floating buildings, transportation and packaging, ships, etc., can solve the problems of frequent erosion and deposition of high sediment flow, grounding of drilling platforms, platform capsizing and other problems, so as to avoid adverse effects, Effect of reducing erosion and silting changes and facilitating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

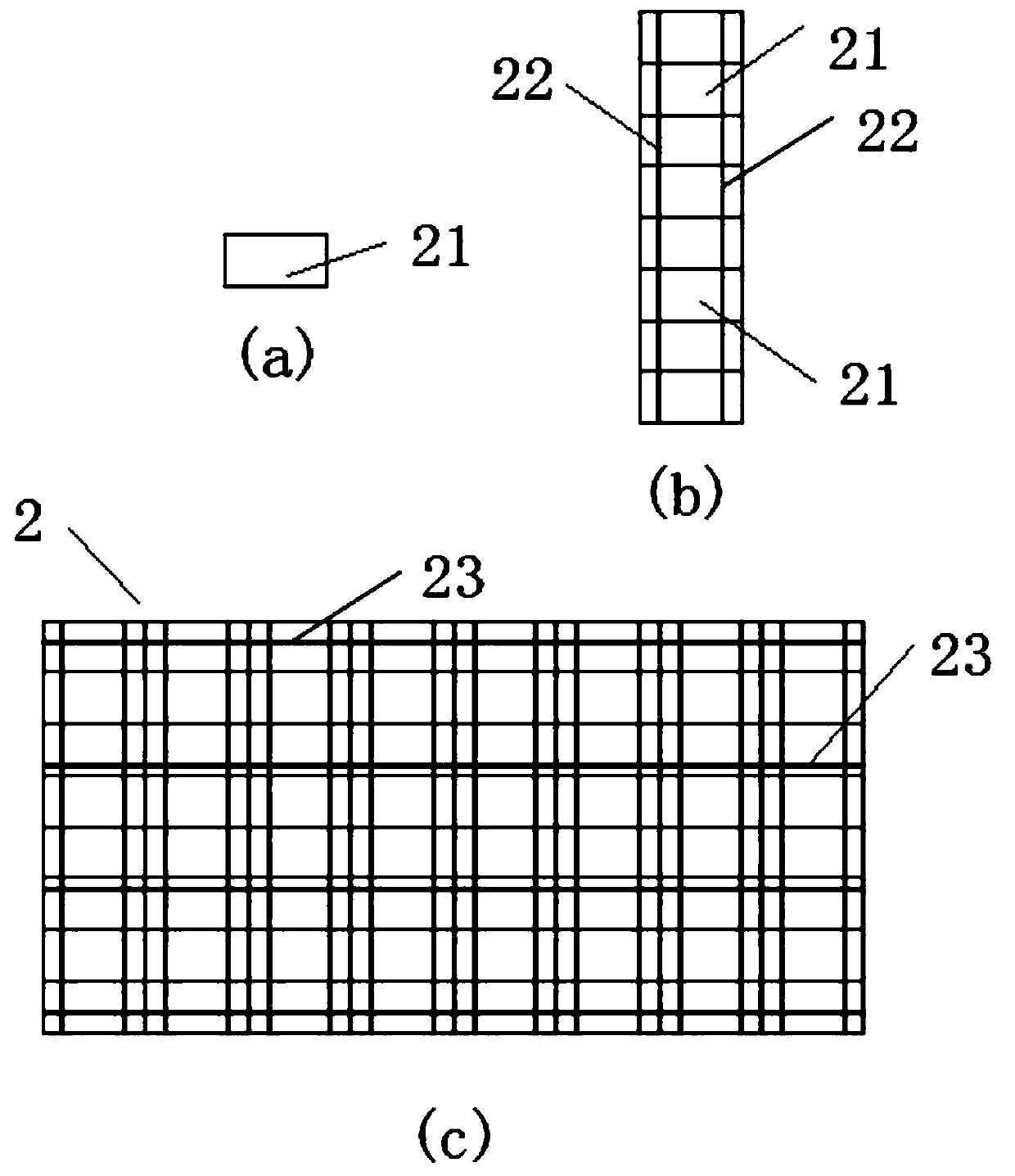

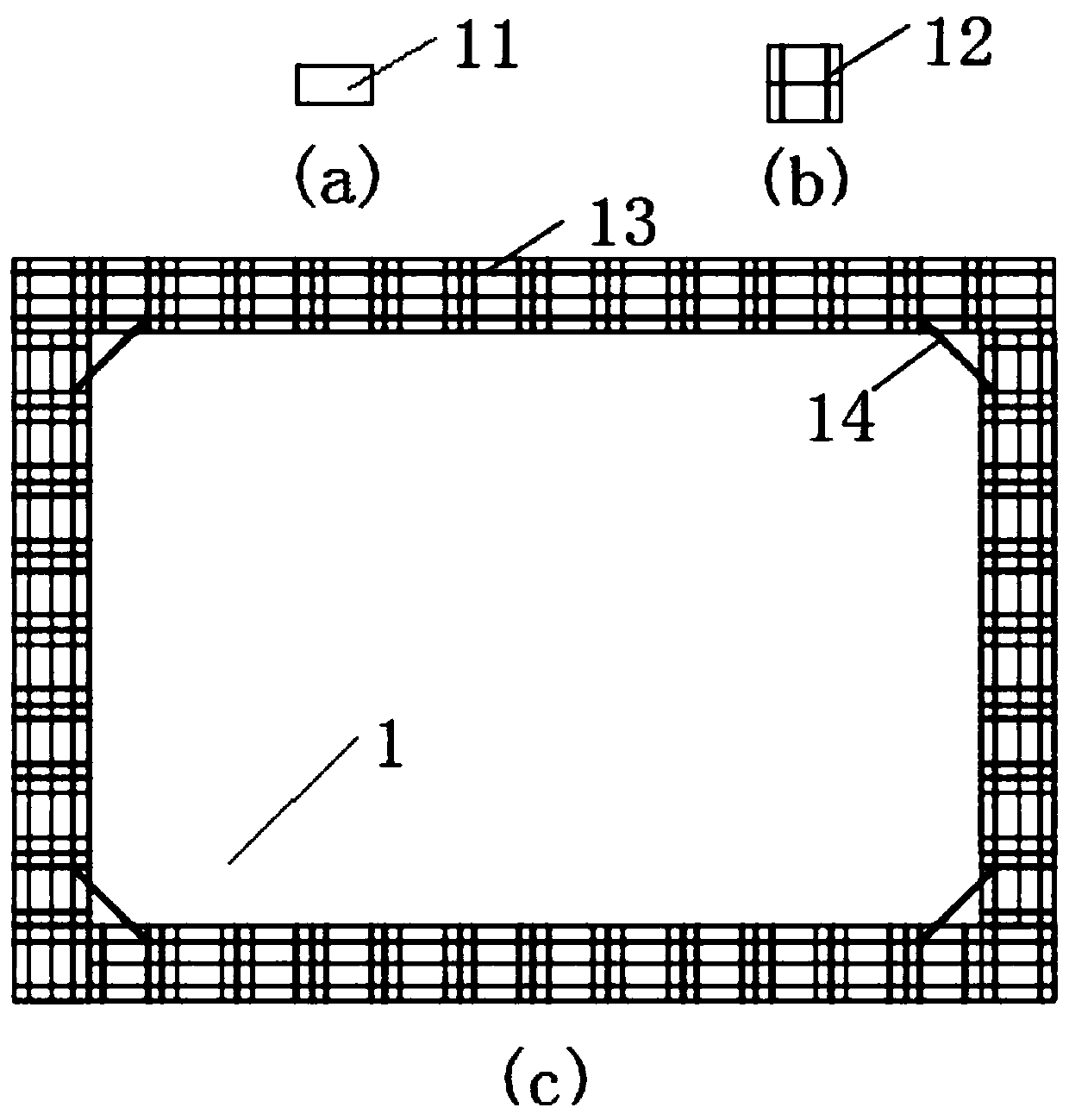

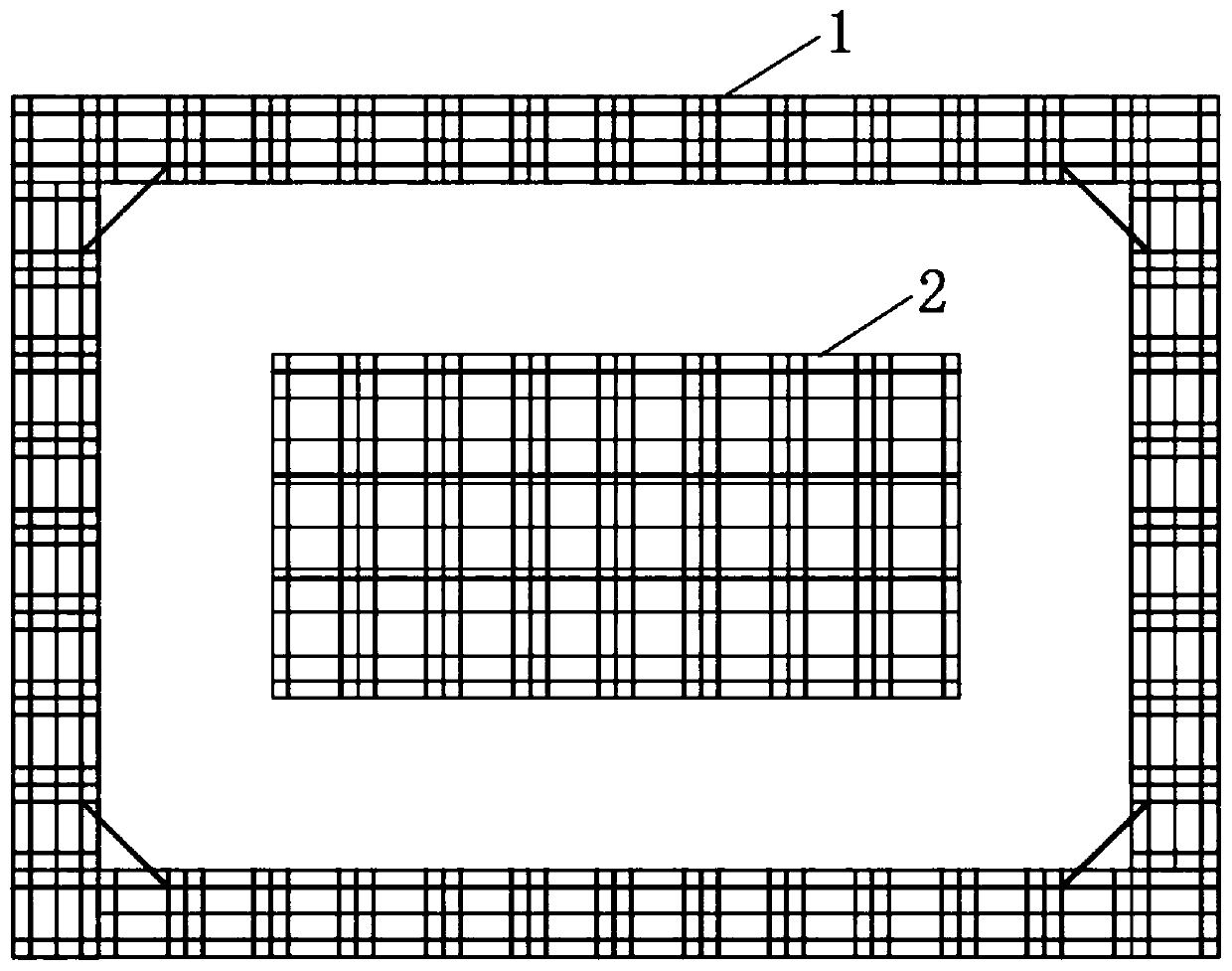

[0031] Referring to the accompanying drawings, it can be seen that the assembled ring-pull water drilling platform includes an external buoy group 1 and an internal buoy group 2. The external buoy group 1 includes a buoy 11, an external transverse connecting steel beam 12 located on the upper part of the buoy The external longitudinal connecting steel beam 13 on the upper part of the steel beam 12; a plurality of buoys 11 are fixed on the external horizontal connecting steel beam 12 in a row, and a plurality of rows of buoys 11 are formed by end-to-end connection of the external longitudinal connecting steel beam 13 word type;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com