Automatic measuring method for percentage elongation after single-shaft tensile fracture of metal round bar sample

A technology of elongation after fracture and uniaxial stretching, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and can solve the problem of inaccurate elastic parts, the inability of the extensometer to automatically identify the fracture position of the sample, and the neck of the sample. Reduce the problem of shrinkage, etc., to save measurement time, easy to implement programming, and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

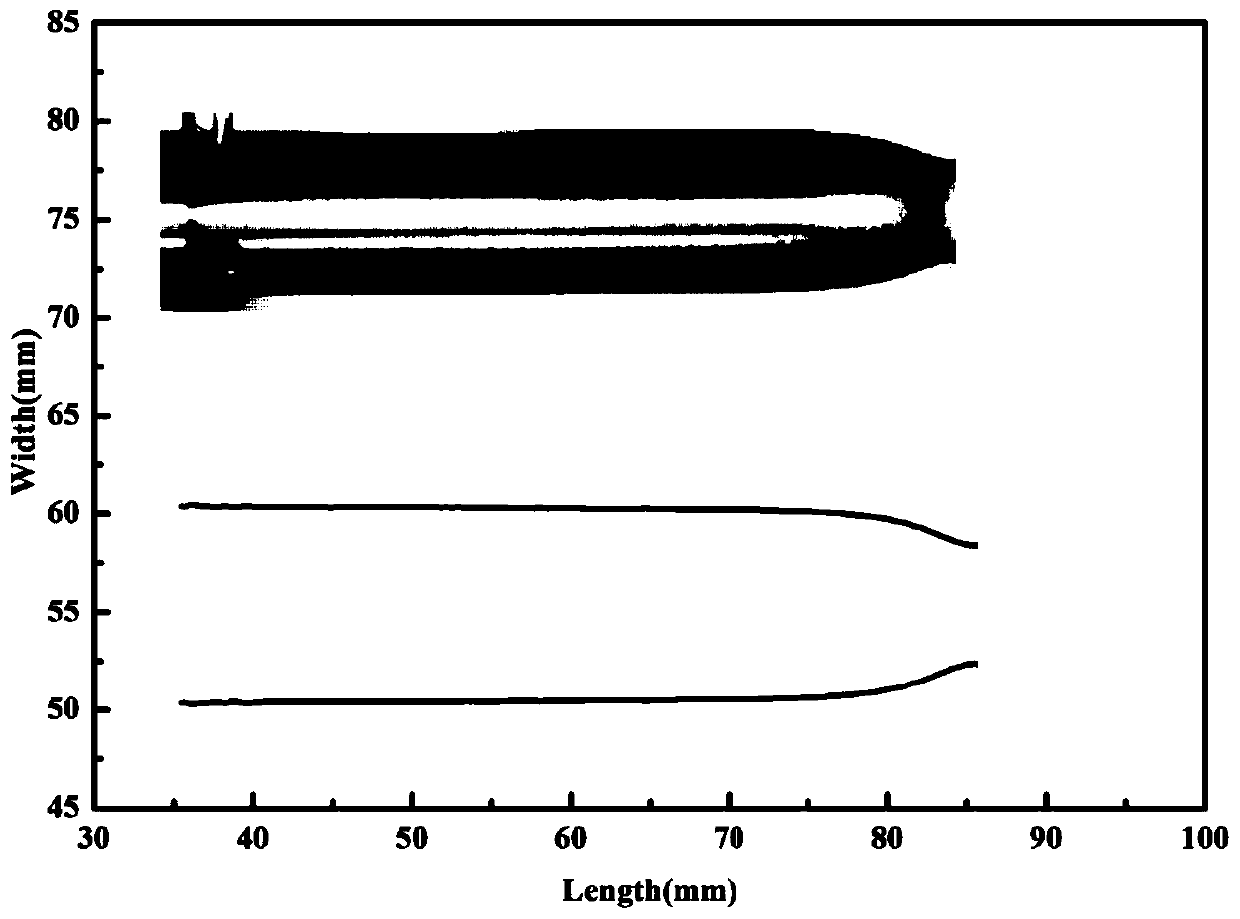

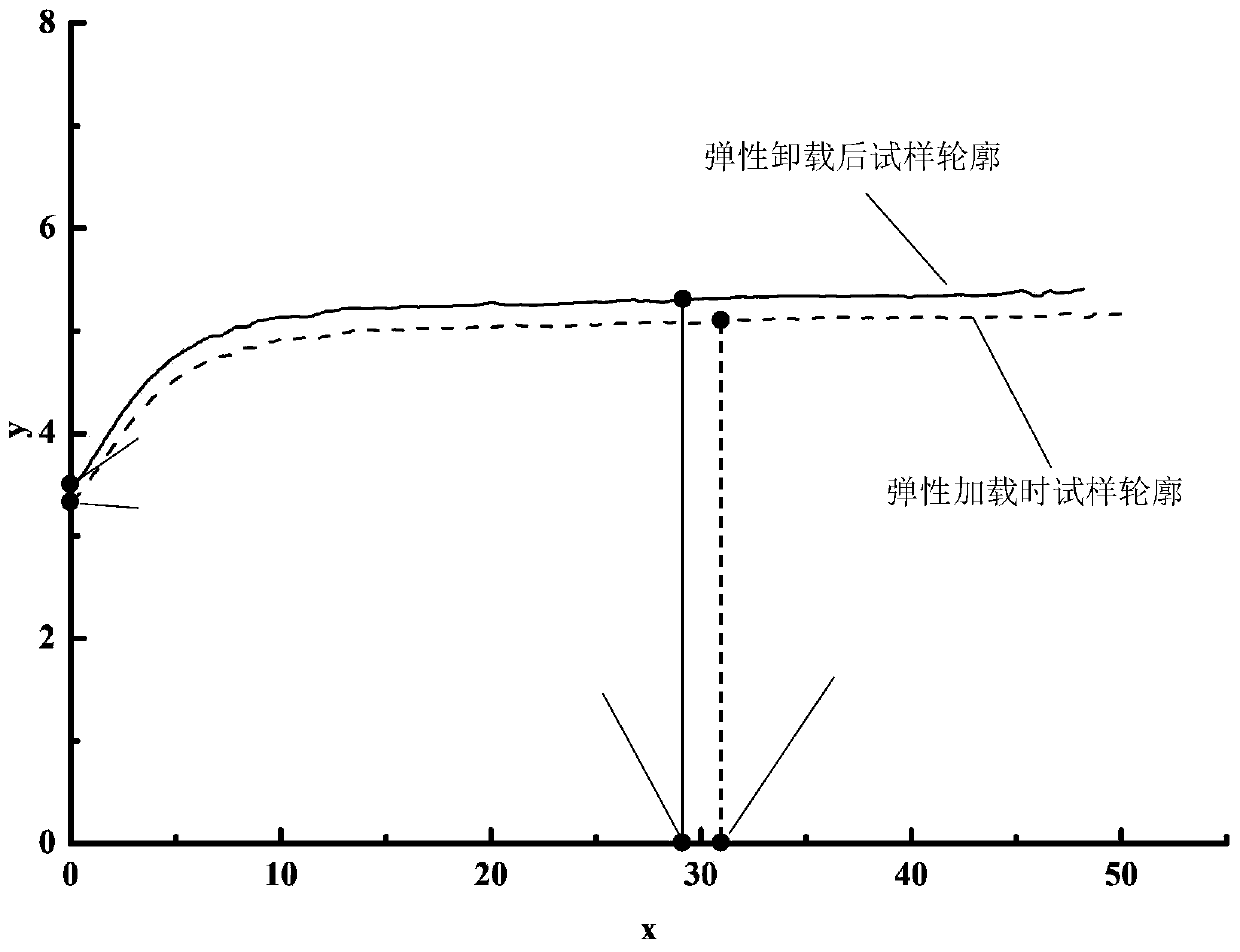

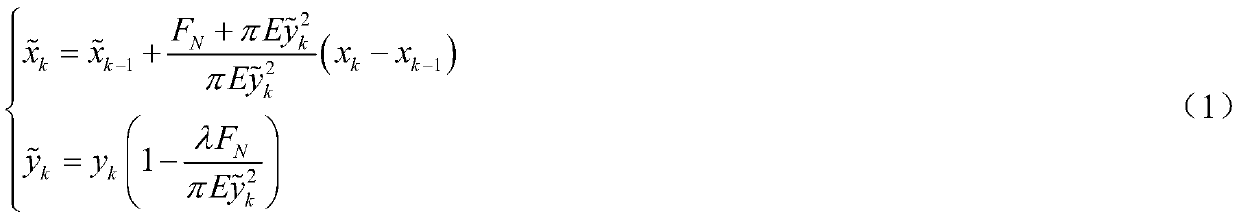

[0023] (1) Carry out the uniaxial tensile test of the low carbon steel round bar sample, the original gauge length is l 0 =50mm, the original gauge length radius is a 0 =5mm, measure and record the load F at the moment of tensile fracture N = 25320N and gauge length elongation dl N =6.125mm, and optically collect the outer contour information of the longer half of the test bar along the axial direction after breaking, such as figure 1 As shown, the coordinates G of each point of the outer contour curve are obtained by image processing k (x k ,y k ), where k=0~M, 0 and M respectively correspond to the necking fracture point of the sample and a point close to the arc transition part within the parallel length range, and the fracture point is determined by y k The minimum value shall prevail, and the axis coordinate corresponding to the necking fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com