Floor mopping method of floor mopping robot

A floor wiping robot and local method technology, applied in machine parts, cleaning carpets, cleaning floors, etc., can solve the problems of low utilization rate, low degree of intelligence, secondary pollution on the ground, etc., and achieve simple, convenient and intelligent control High, the effect of improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

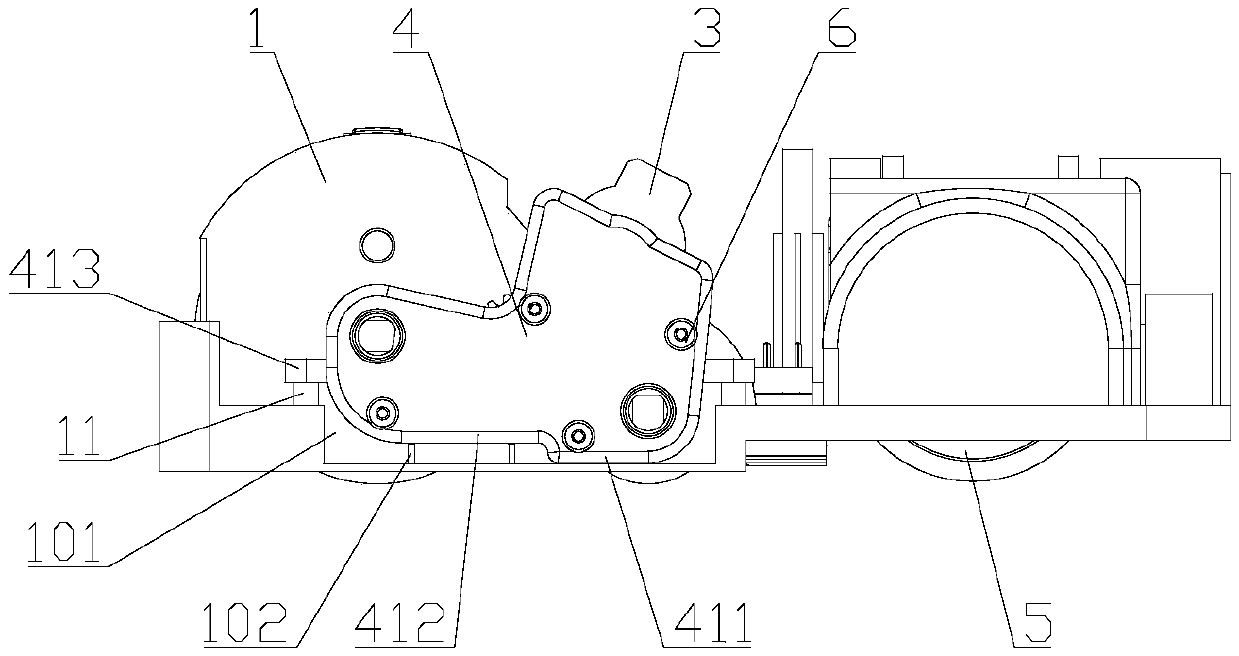

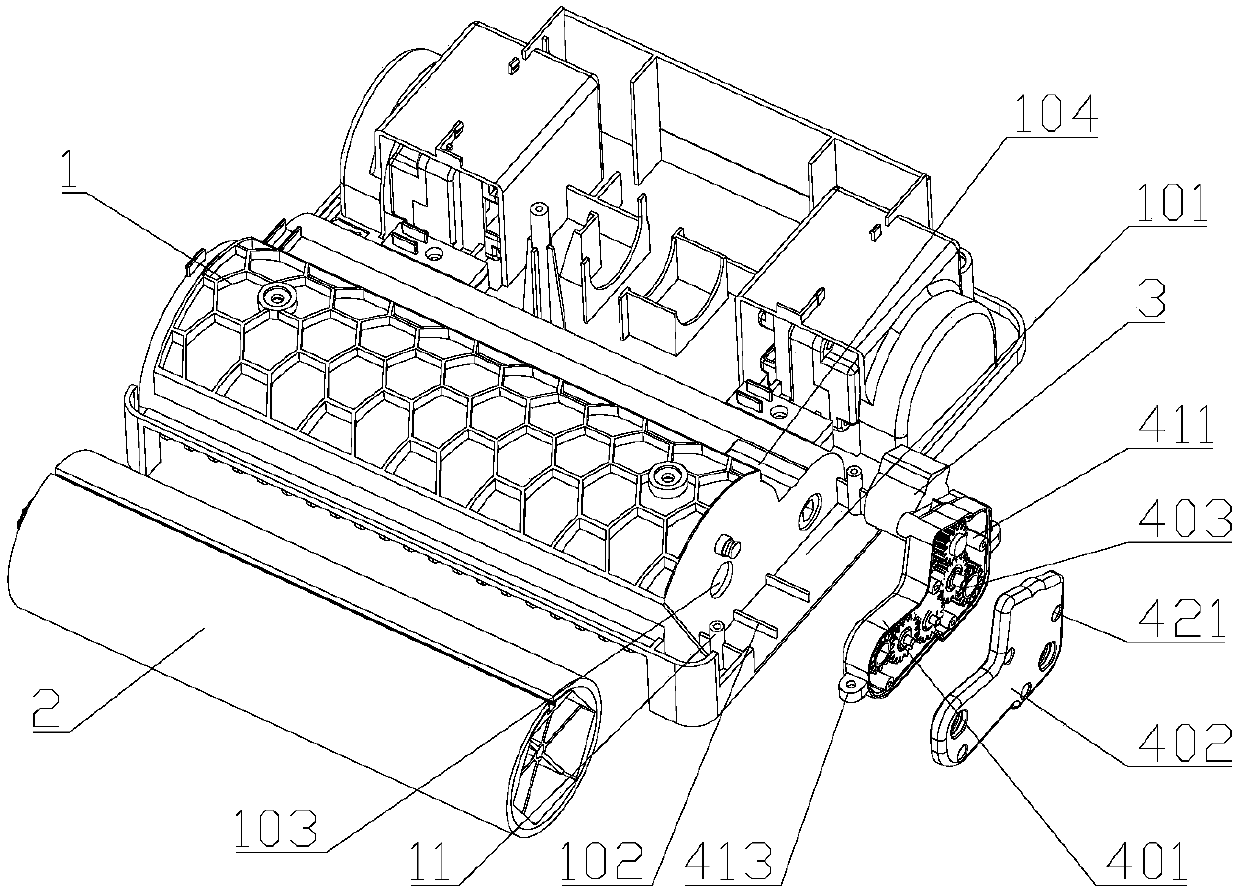

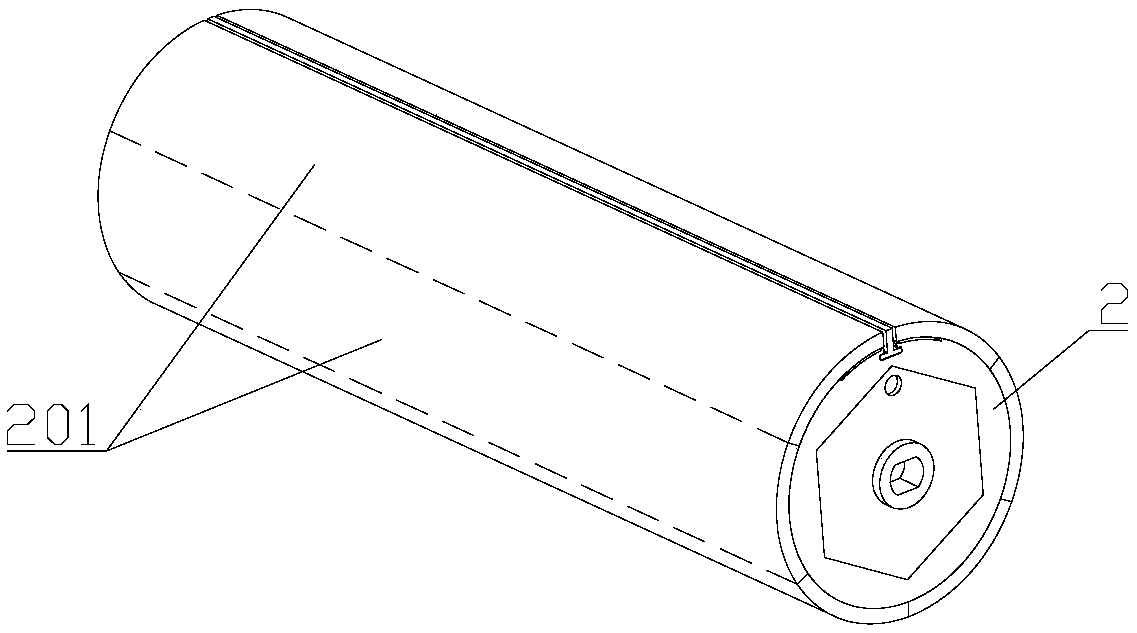

[0024] The present invention at first provides a kind of wiping method of wiping robot, and the structure of wiping robot can refer to figure 1 with figure 2 , including a body 1, a control system, a rotary brush 2 and a motor 3 that drives the rotary brush 2, the control system controls the motor to work, and the ground wiping method includes the following contents: divide the current area to be cleaned into 6 sub-areas, and divide the current area of the rotary brush 2 into six sub-areas. Outer circumference such as image 3 As shown, it is divided into six arcuate sections 201 in the circumferential direction, and the control system controls the intermittent rotation of the motor to drive the rotary shaft to rotate intermittently, so that one arcuate section 201 corresponds to cleaning a sub-area, image 3 The dotted line in is for the convenience of distinguishing different arcuate segments 201 , and there may not be a clear boundary between two arcuate segments 201 in...

Embodiment 2

[0034]In addition to simply letting an arc segment correspond to cleaning a sub-area, the body can also be equipped with a first sensor to detect the degree of dirt in the current sub-area. The control system sets the threshold of the degree of dirt, and the mopping robot detects a Whether the degree of dirtiness of the sub-area reaches the threshold value, if so, the control system controls the corresponding cleaning of the sub-area by multiple arc surface segments, if not, the control system controls the corresponding cleaning of the sub-area by one arc surface segment. Detecting the degree of dirt on the ground is a common technique in this field, and there have been many patent publications, which will not be repeated here. Reasonable planning of the use of the arc surface segment according to the actual situation can improve the cleaning effect.

[0035] For other content not described in this embodiment, refer to Embodiment 1.

Embodiment 3

[0037] In order to improve the use efficiency of the arc section, the body can be equipped with a second sensor to detect the degree of dirtiness of the current arc section and a third sensor to detect the ground material of the sub-area. The sensor detects whether the degree of dirtiness of the currently used arc section reaches the threshold, and at the same time, the third sensor detects whether the ground material of the next sub-area is different from the ground material of the previous sub-area that has been cleaned. If either is yes, Then the control system controls to replace a new arc surface segment, if all are negative, then continue to use the current arc surface segment for cleaning. That is to say, if the degree of dirtiness of the currently used arc segment has not reached the threshold, and the ground material of the next sub-area is the same as that of the previous sub-area that has been cleaned, the control system will not replace the arc segment and continue ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap