Split type junction box

A junction box and split-type technology, which is applied in the field of split-type boxes, can solve the problems of decreased protection performance and achieve the effects of improving sealing performance, reducing body cuts or material cuts, and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

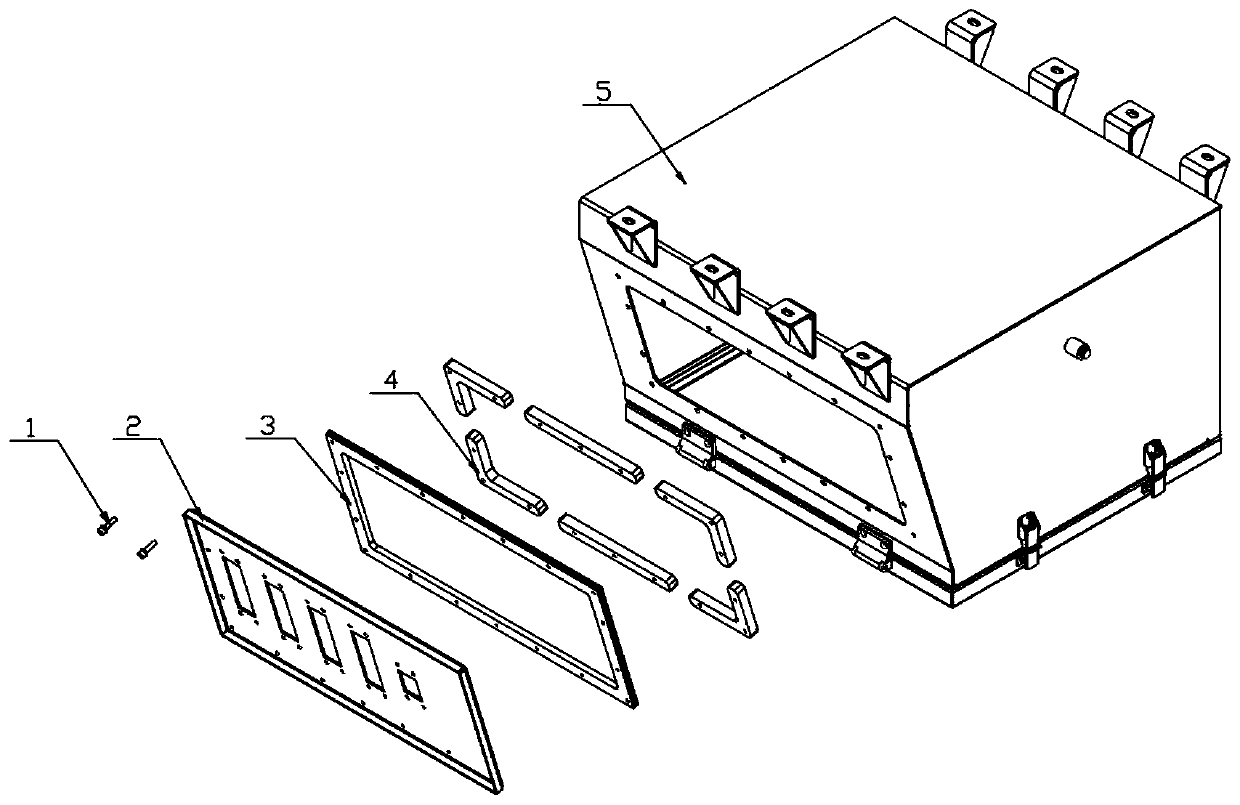

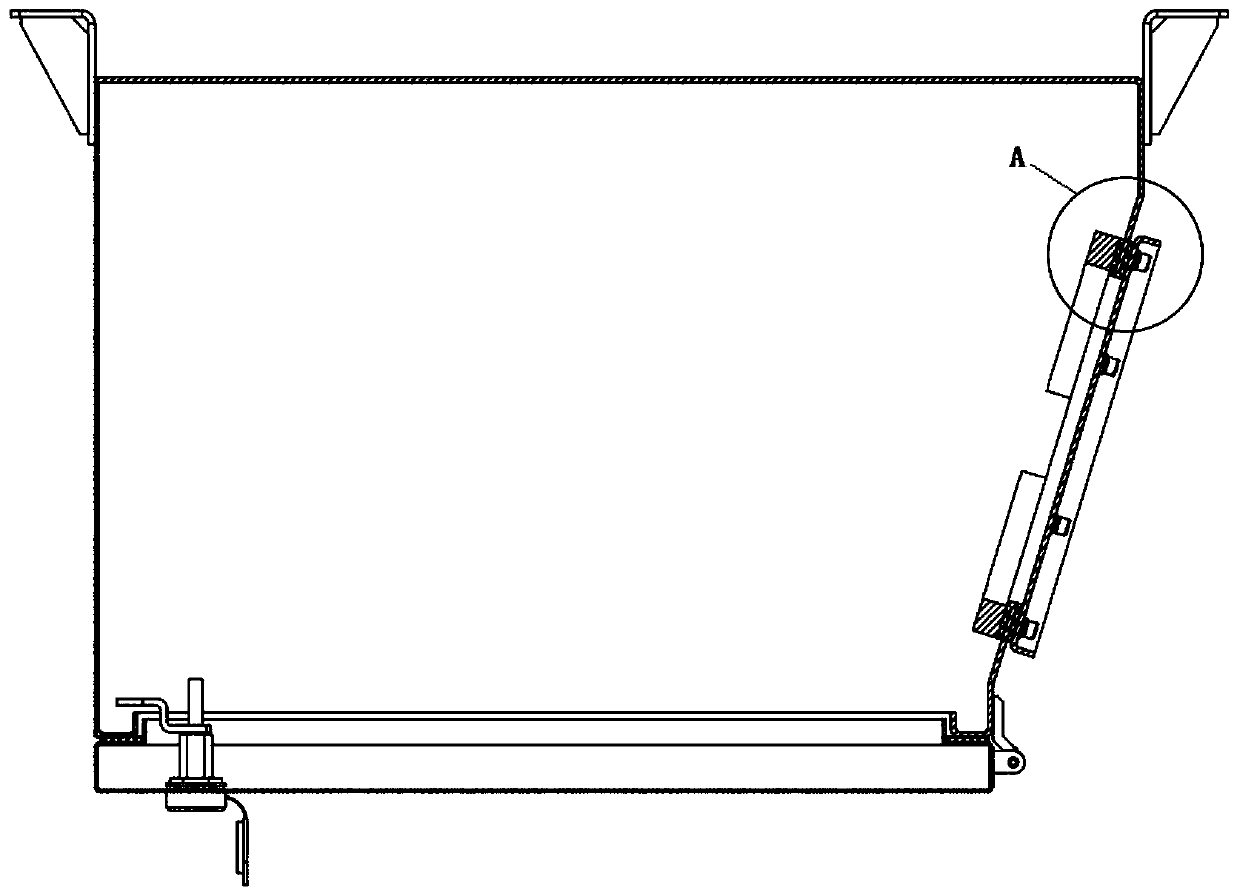

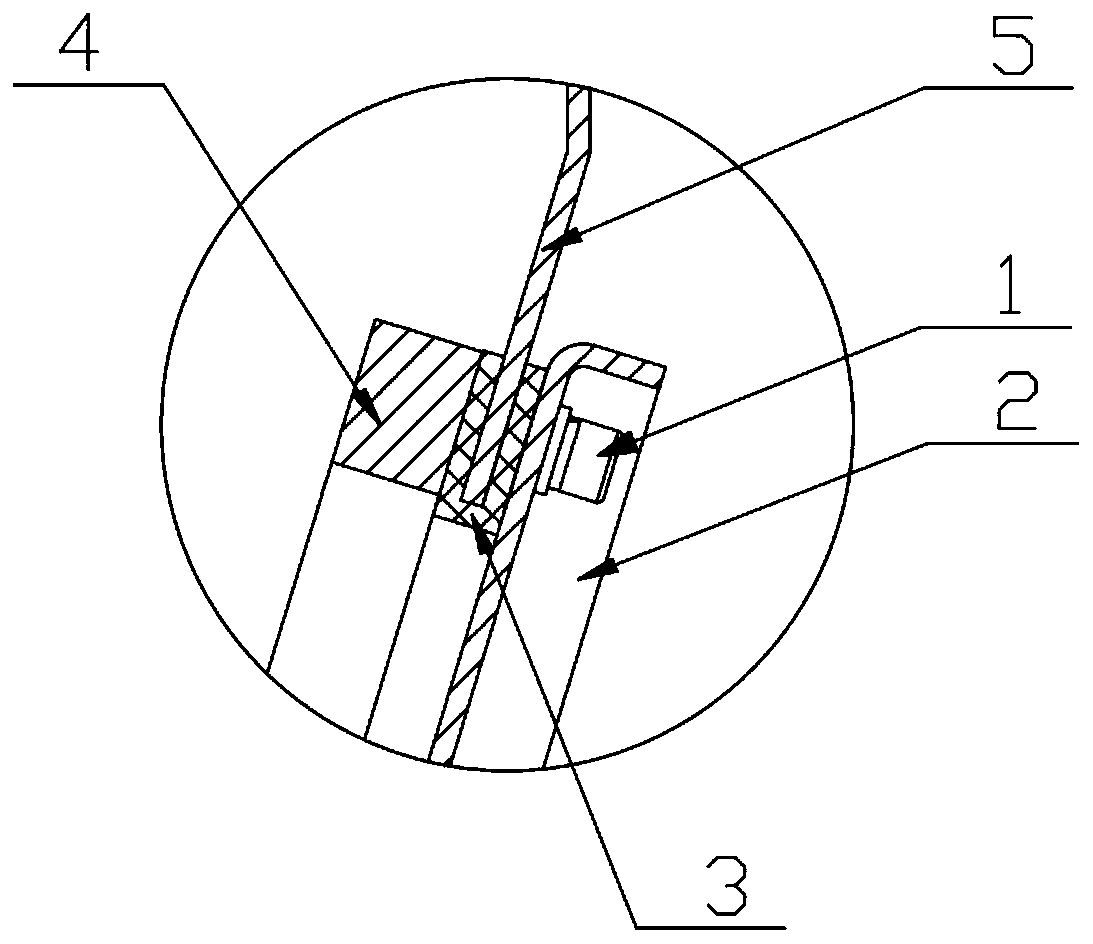

[0028] Such as figure 1 and 4 As shown, a split junction box includes screws 1, panels 2, U-shaped rubber sealing strips 3, pressing parts and box body 5; box body 5 is provided with a center hole 1, and is evenly distributed on the edge of the center hole. n through-holes, n≥6; if the central hole is a round hole, all the through-holes are evenly distributed along the circumferential direction of the central hole; if the central hole is a square hole, the through-holes are along the length direction of the central hole Arranged equidistantly, also equidistantly arranged along the width direction; the pressing part is an integral structure, with n blind holes provided with internal threads; the central axes of n blind holes and n through holes are aligned One alignment. The overall shape of the U-shaped rubber sealing strip 3 is consistent with the shape of the central hole 1; the end surface of the U-shaped rubber sealing strip 3 is provided with a central hole 2 coaxially ...

Embodiment 2

[0032] Except that the pressing part adopts a split structure, the rest of the structure is exactly the same as that of the first embodiment; the pressing part includes n / 3 pressing blocks 4; each pressing block is provided with 3 blind holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com