Independent modularized dish-washing machine and manufacturing method thereof

A modular dishwasher technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problems of small space occupation rate, reduce maintenance cost, etc., and achieve The space occupancy rate is small, the maintenance cost is reduced, and the cleaning effect is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

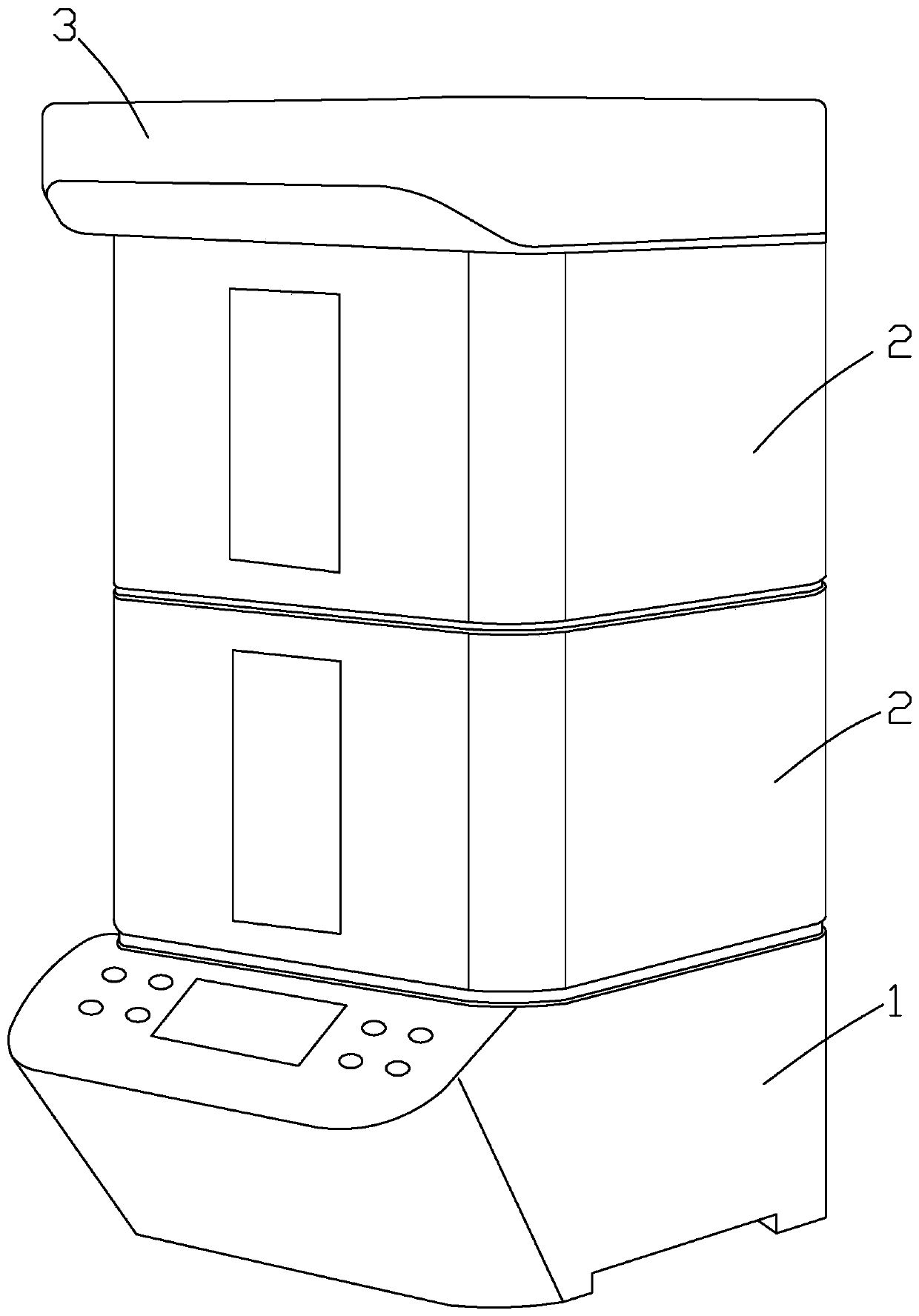

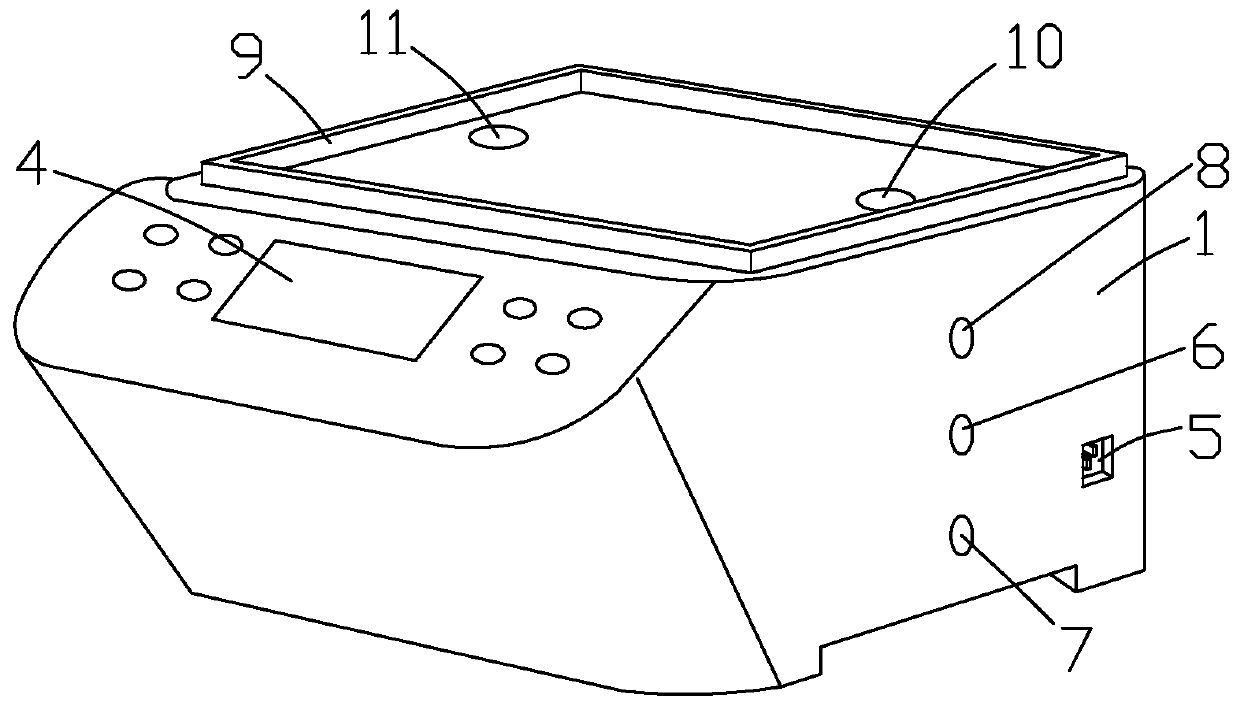

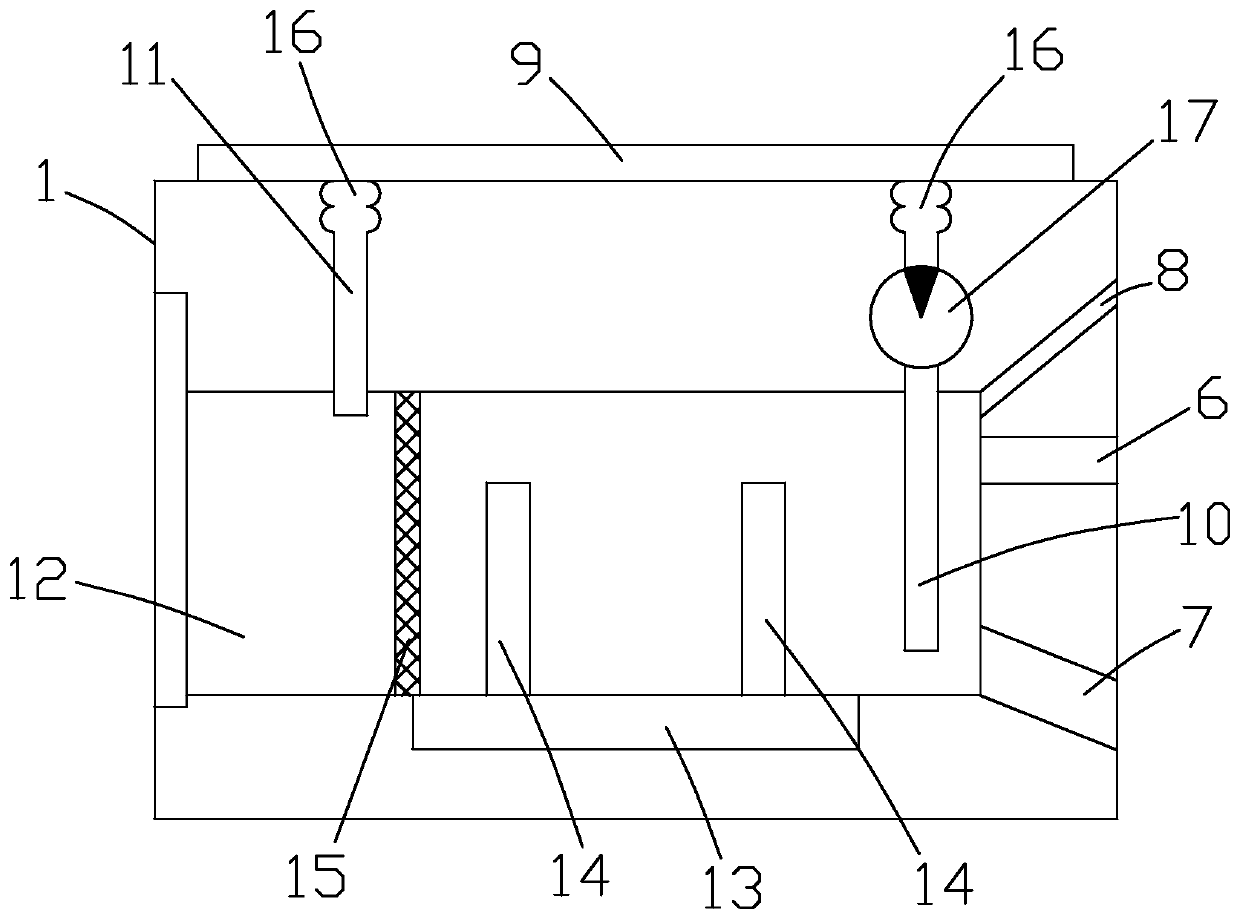

[0048] Such as Figure 1 to Figure 8 As shown, it is a stand-alone modular dishwasher according to the present invention, which includes a base 1, a top cover 3 and at least one modular dishwashing box 2, and a water storage tank 12 and a controller are arranged horizontally inside the base 1 to store water One side of the tank 12 is connected with a protective door, and the other side of the water storage tank 12 is provided with a detergent input pipe 8, a water inlet pipe 6 and a water outlet pipe 7 sequentially from top to bottom, and a first seal is arranged on the top surface of the base 1. Bar 9, the base 1 is provided with a first water delivery pipe 10 and a first return pipe 11, the first water delivery pipe 10 and the first return pipe 11 are located inside the first sealing strip 9, the first water delivery pipe 10 and the first return flow pipe The top ends of the pipes 11 are provided with a first corrugated hole 16, the first corrugated hole 16 runs through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com