Movable vertical waste compression transfer station

A garbage compression and mobile technology, which is applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of unfavorable promotion and application, long transfer period, and increased garbage transfer costs, so as to avoid environmental pollution and increase the amount of garbage storage , Improve the effect of garbage disposal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

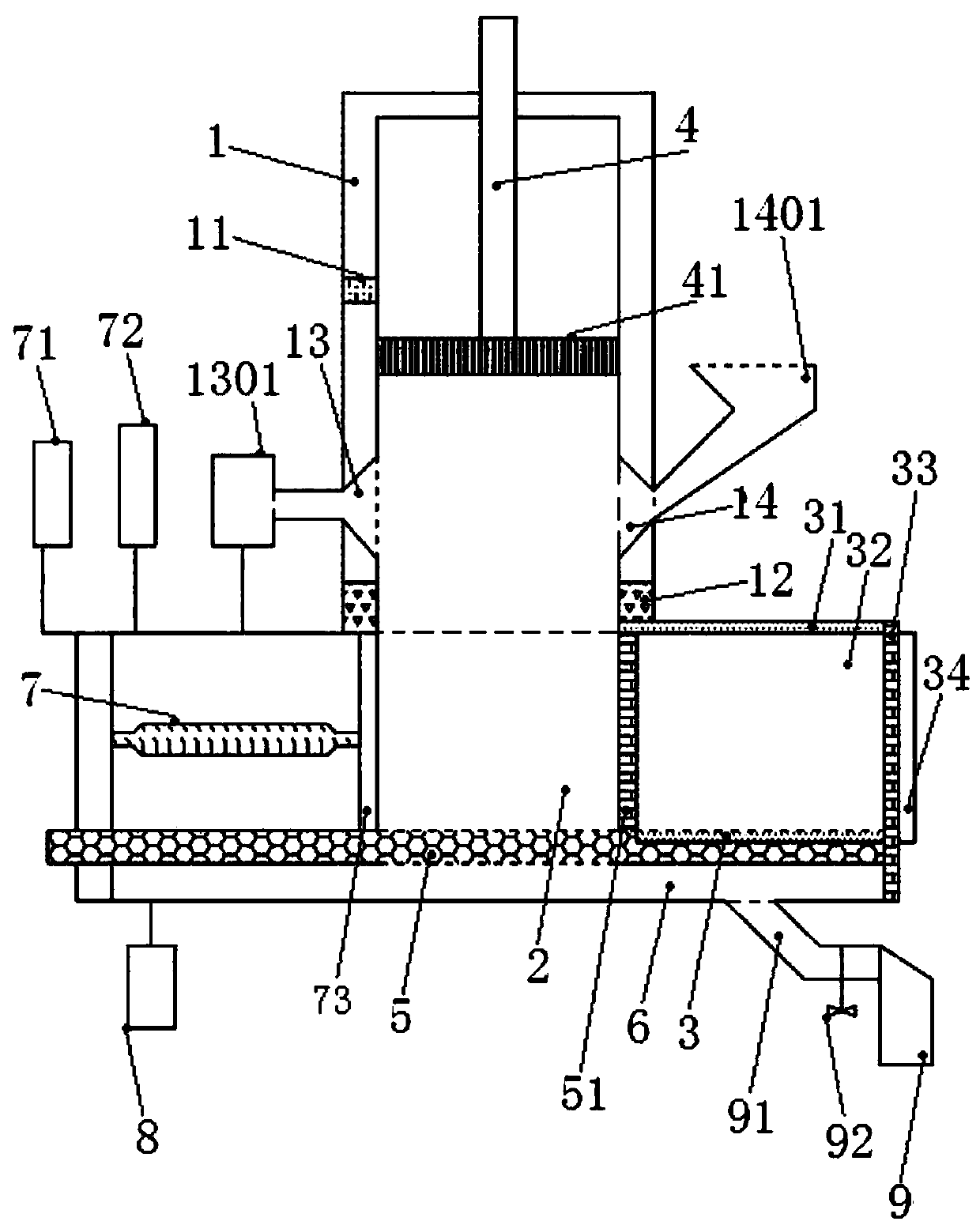

[0028] Such as figure 1 As shown, a mobile vertical garbage compression transfer station is characterized in that the structure includes a frame (1), a compression chamber (2) arranged inside the frame (1), and a storage chamber is arranged on the right side of the compression chamber (2) (3), the main compression oil cylinder (4) is arranged directly above the compression chamber (2), and the inside of the main compression oil cylinder (4) is provided with a stainless steel pressure head (41) that can slide up and down along the inner wall of the main compression oil cylinder (4). The caliber of the head (41) matches the caliber of the inner wall of the compression chamber (2); the left side of the compression chamber (2) is a horizontal push device (7), and the right end of the horizontal push device (7) is provided with a horizontal push head (73), and the horizontal The push head (73) is positioned on the left edge of the compression chamber (2);

[0029] The compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com