Same-layer drainage whirlcone composite member

A technology for same-layer drainage and cyclone, which is applied in water supply installations, indoor sanitary piping installations, buildings, etc., can solve the problems of increasing construction costs, complicated installation procedures, and lack of ground drainage functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

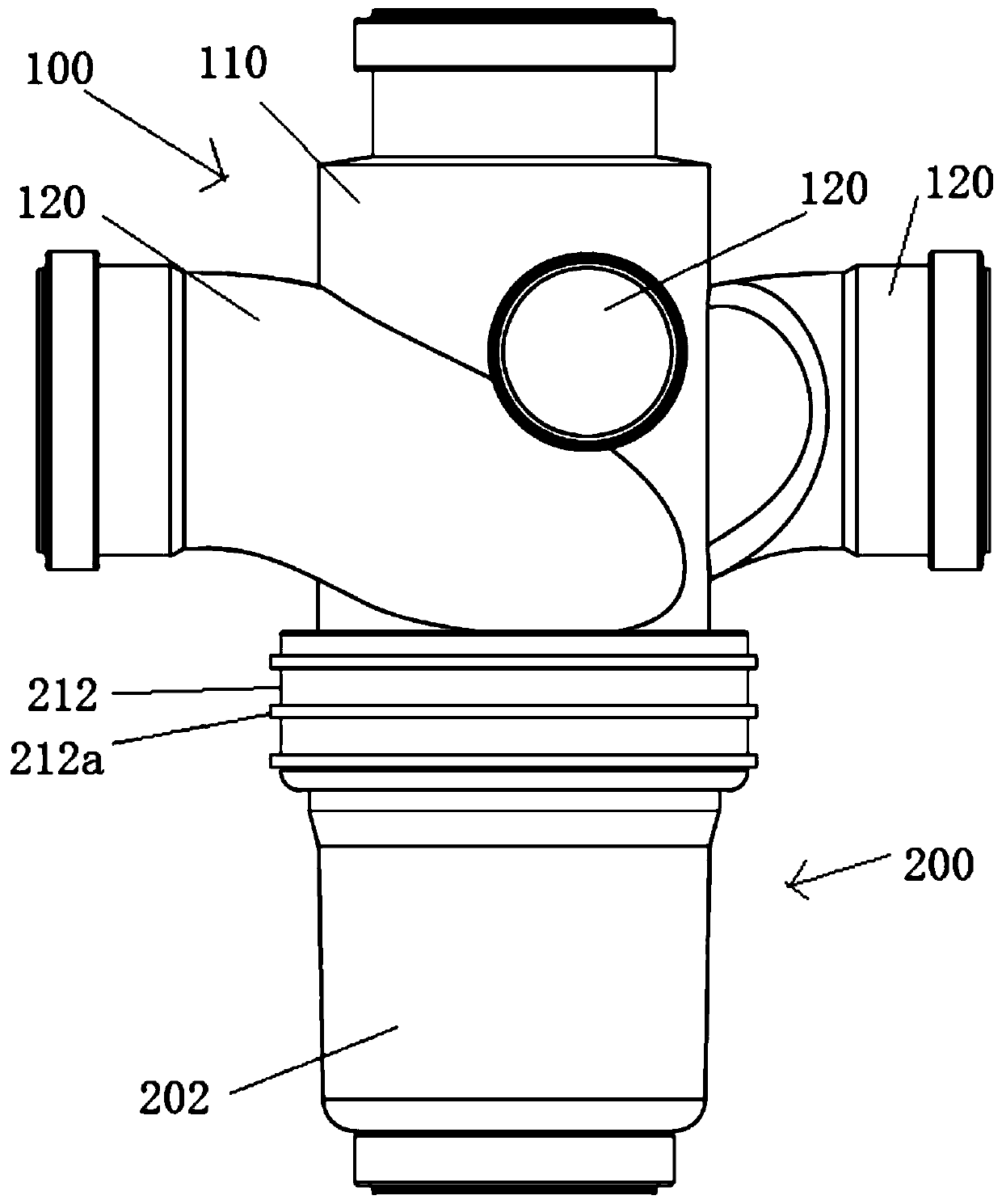

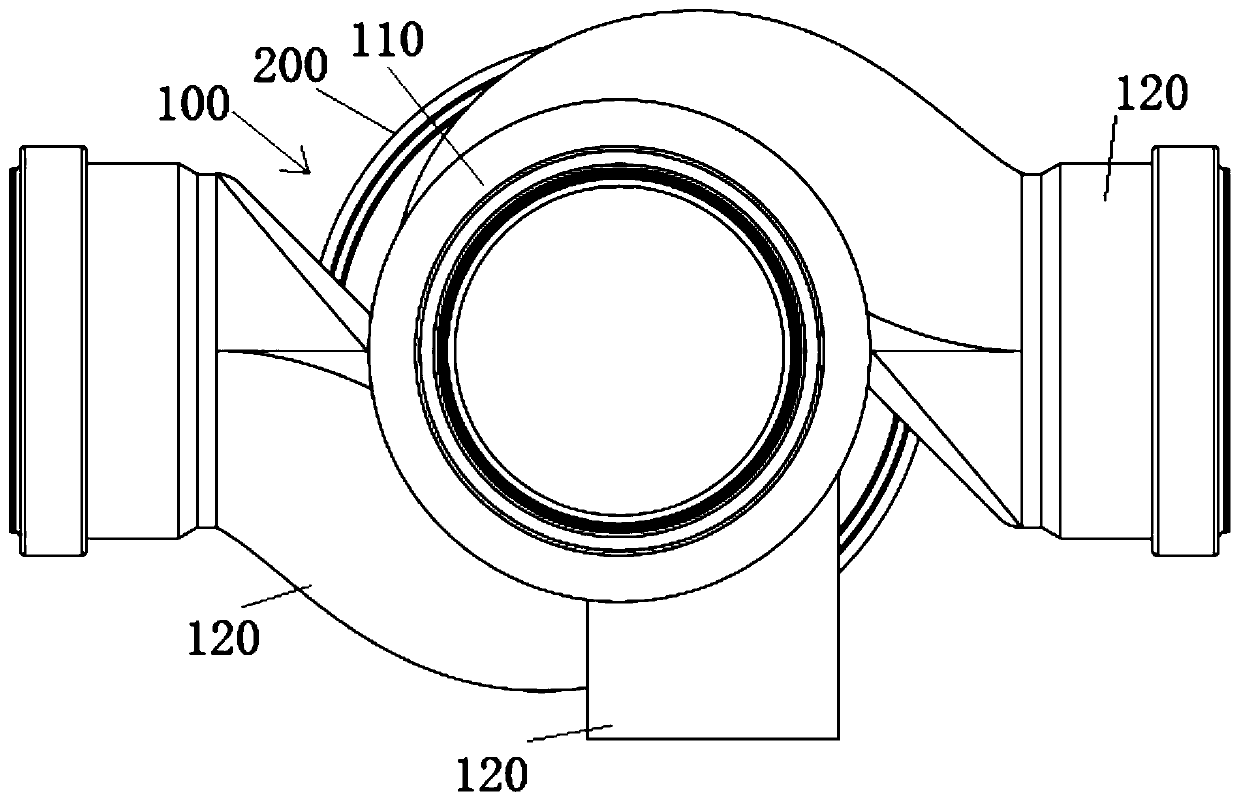

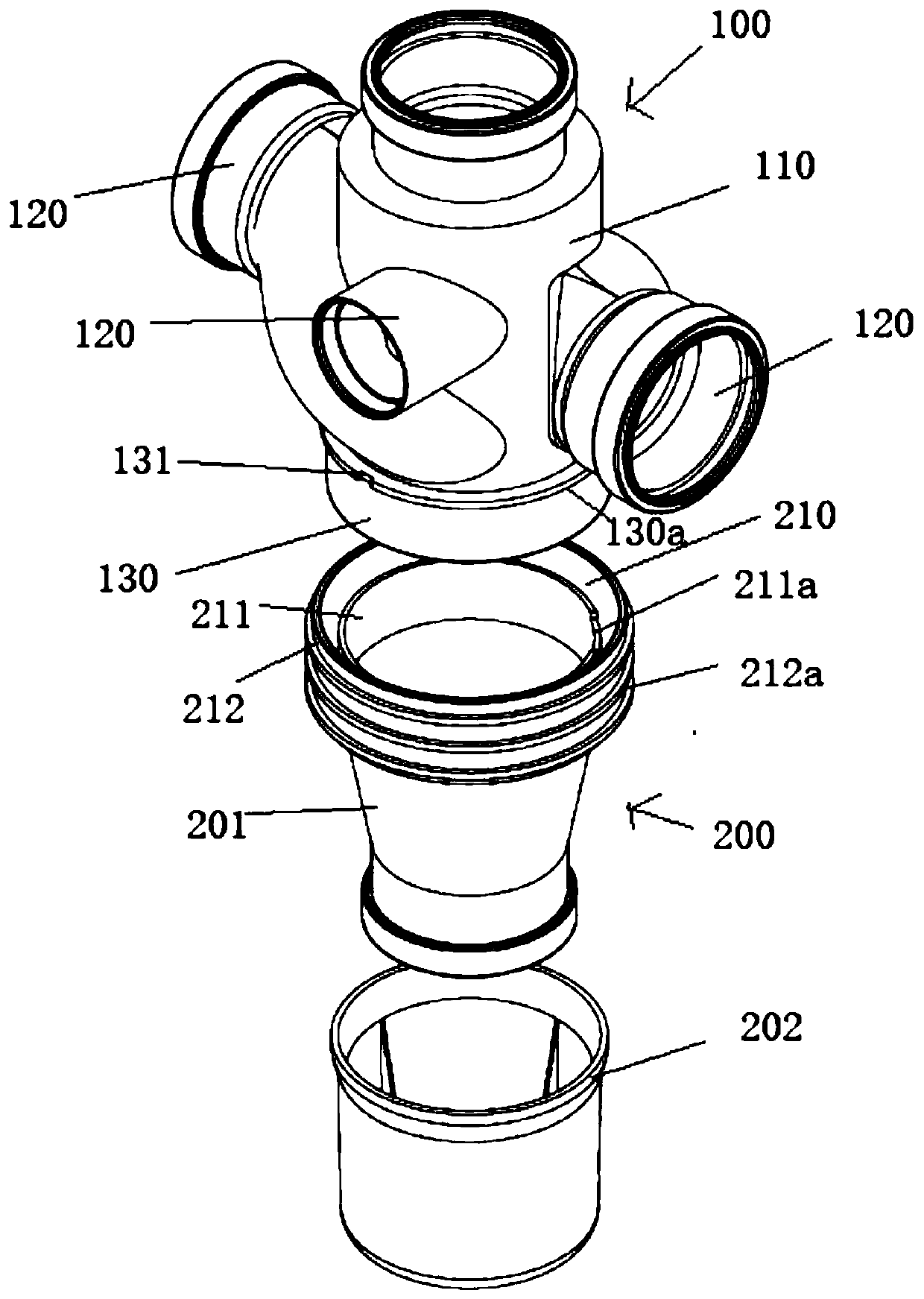

[0017] see Figure 1 to Figure 5 The shown one-level drainage cyclone assembly includes a cyclone body 100 and a lower drain pipe 200 connected to the bottom of the cyclone body 100 . The outer circumference of the top of the lower drain pipe 200 is provided with an annular groove 210, and the top of the inner wall 211 of the annular groove 210 is provided with at least one accumulated water outlet 211a. The main standpipe section 110 and several lateral branch pipe sections 120, the bottom of the cyclone body 100 is provided with a cylindrical part 130 inserted into the annular groove 210, the top of the cylindrical part 130 is sealed with the top of the outer wall 212 of the annular groove 210, specifically, the cylindrical part The top of the cylinder 130 is provided with an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com