Modularization same-layer drainage device for high-rises and mounting method thereof

A same-layer drainage and modularization technology, applied to water supply devices, drainage structures, waterway systems, etc., can solve the problems of long construction period, waste of materials, increase of structural self-weight load, etc., to avoid hidden dangers of leakage, reduce consumption of building materials, Optimize the effect of space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

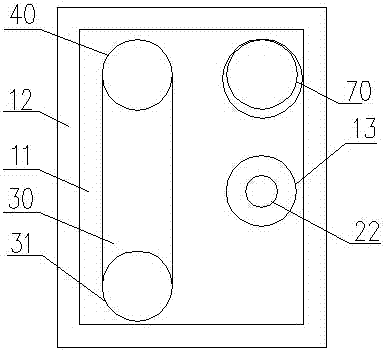

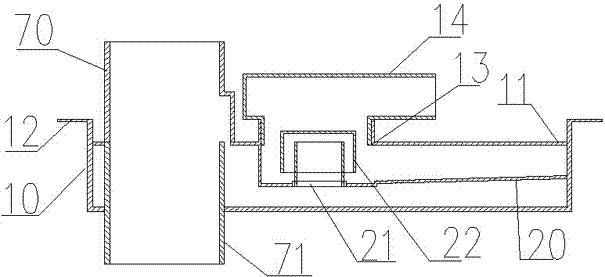

[0056] Such as Figure 1-4 As shown, a modular same-floor drainage device for high-rise buildings includes a water collection box 10, a standpipe connecting pipe 40 pierced in the water collection box 10, and passes through the bottom wall of the water collection box 10 and is equal to the top cover 11 of the water collection box. The lower ventilation pipe 71 at the highest point, the upper ventilation pipe 70 that is located on the top cover 11 of the water collection tank and communicates with the interior of the water collection tank 10, and the waste water discharge port 13 that is opened on the top cover 11 of the water collection box, the upper ventilation pipe 70 and the lower ventilation pipe 70 There is a gas flow channel between the ventilation pipes 71, and the standpipe connecting pipe 40 is provided with a water outlet 41 located in the water collection tank. The mechanism is connected with the water outlet 41, and the waste water discharge port 13 is equipped wi...

Embodiment 2

[0059] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the highest point of the lower ventilation pipe 71 is lower than the top cover 11 of the header tank, and the upper ventilation pipe 70 is a straight pipe and is arranged correspondingly to the lower ventilation pipe 71 .

Embodiment 3

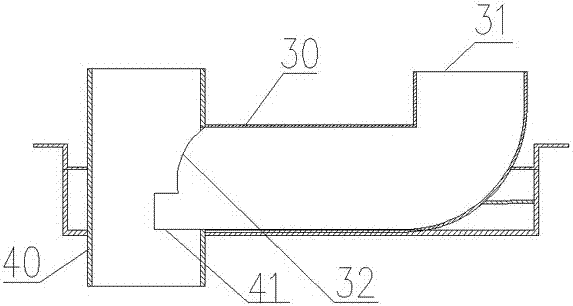

[0061] Such as Image 6 As shown, the difference between this embodiment and embodiment 2 lies in that the cross-section of the waste water drainage pipe is circular, and the sewage pipe 30 is a bent pipe, and the bent portion of the sewage pipe 30 is arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com