Contact box for switch cabinet

A technology of contact box and switchgear, applied in the field of contact box, to achieve the effect of avoiding corona, eliminating air gap, and simple structure improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

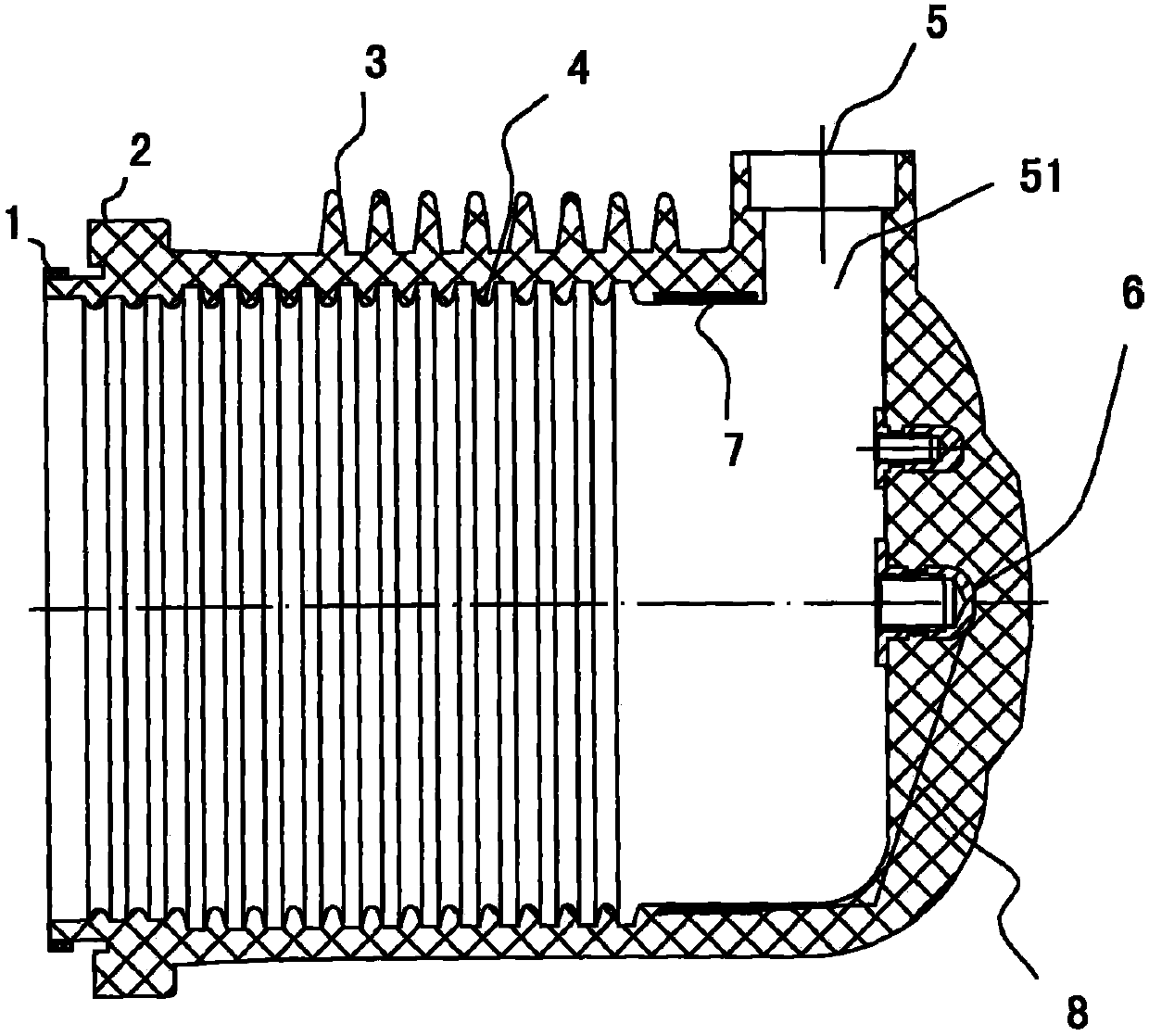

[0010] see figure 1 . The cylindrical insulator 2 molded by epoxy pressure gel has an inner skirt 4 and an outer skirt 3 on the inner and outer walls respectively. The silicon rubber ring 1 is arranged on the periphery of the base connecting port at the bottom of the cylindrical insulator 2, and the base connecting port is used for connecting with the plastic connecting seat during installation. The metal cylinder shielding layer 7 can be a wire mesh layer or a metal sheet layer, which is ring-shaped on the inner wall of the female discharge line opening 5 side. For integral casting. The metal cylinder shielding layer 7 is made of non-magnetic materials such as aluminum and copper, and is connected with the static contact mounting insert 6 with a wire connecting wire 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com