Flat wire motor stator

A motor stator and flat wire technology, applied to the shape/style/structure of winding conductors, can solve the problems of large size, difficulty in winding and forming of windings, damage of winding wires, etc., achieve high production efficiency and save secondary Injury, good adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

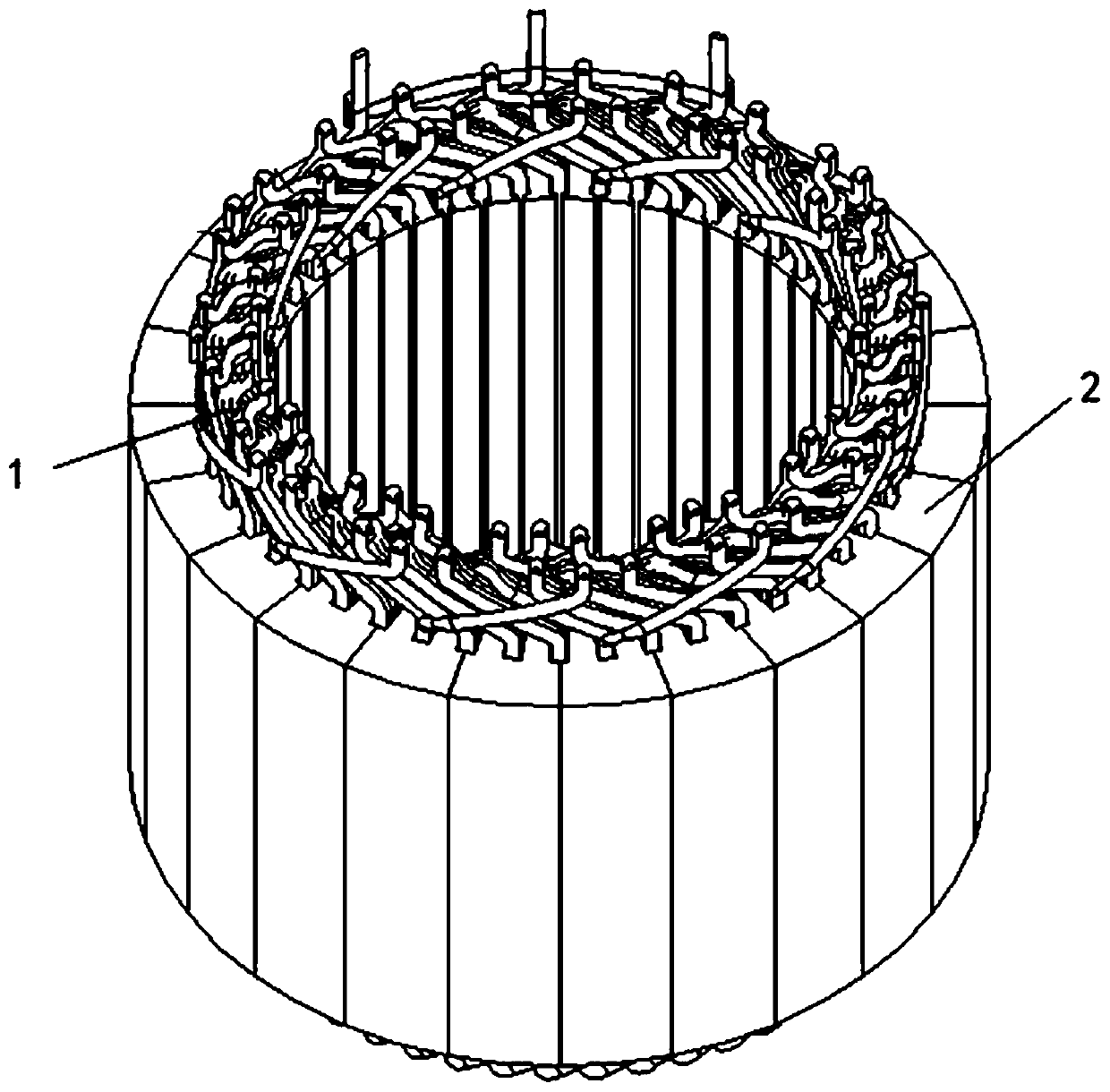

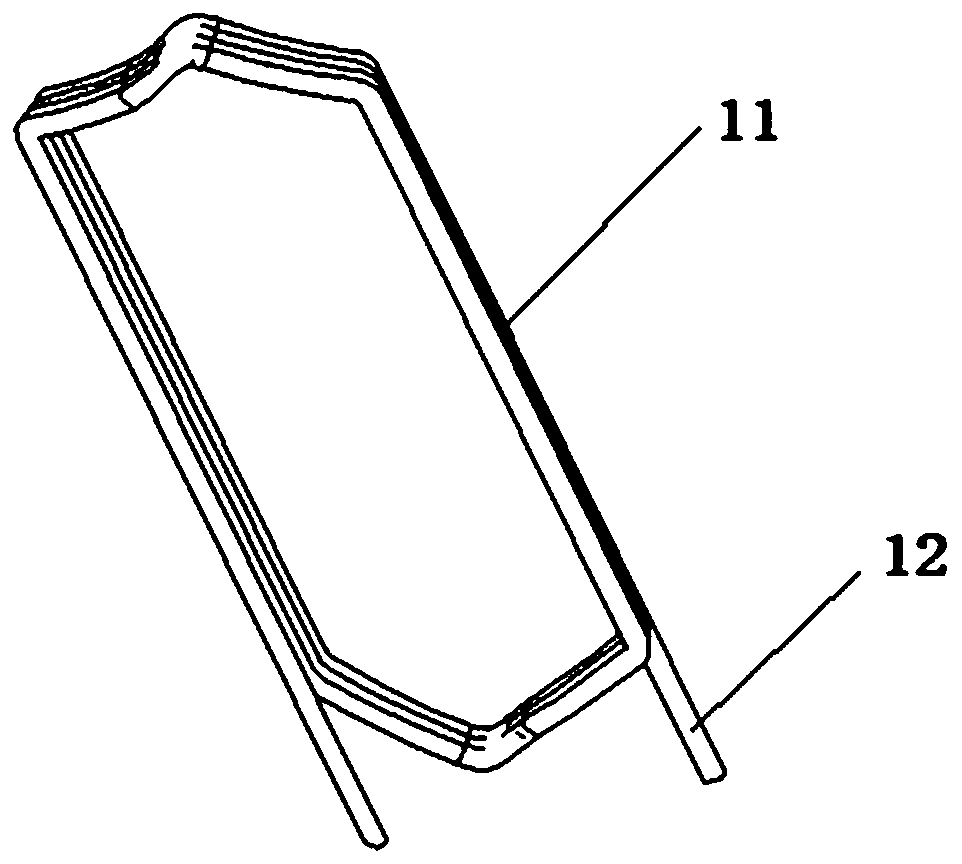

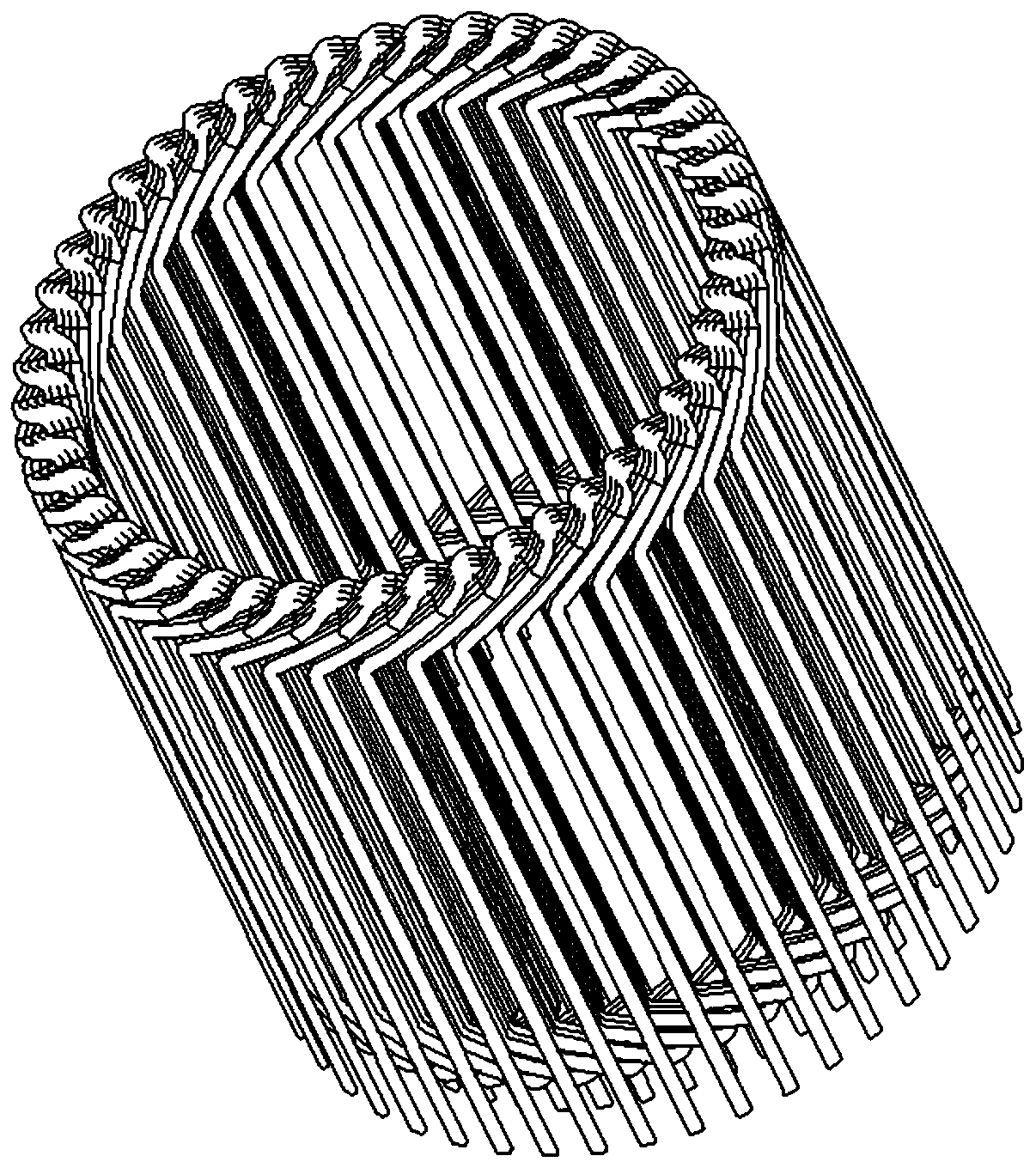

[0034] Such as figure 1 As shown, the present invention discloses a flat wire motor stator, which includes a stator winding 1 and a stator core 2 . The stator winding 1 includes several stacked winding units 11, such as figure 2 As shown, the folded winding unit 11 is formed by winding four turns of a flat wire conductor, and has two lead wires 12, and the two lead wires are at the same end; After bending, it is welded sequentially according to the wiring mode of the winding to form a combination of stacked winding units. There are 48 stacked winding units in the entire stator winding, such as image 3 shown.

[0035] The stator core 2 includes several segmented stator cores 21, such as Figure 4 As shown, the end of each segmented stator core 21 has two stator core teeth 22, a stator core slot 23 is formed between the two stator core teeth, and the stator irons of the adjacent two segmented stator cores A stator core slot is also formed between the core teeth, and a comp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap