Oil pipe centralizing connecting bolt

A technology for connecting bolts and oil pipes, which is applied in the direction of drilling pipes, casings, drilling equipment, etc., can solve the problems of broken seal rings, hanger seal rings, time-consuming and labor-intensive problems, and achieve the goal of ensuring successful construction and avoiding rework Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

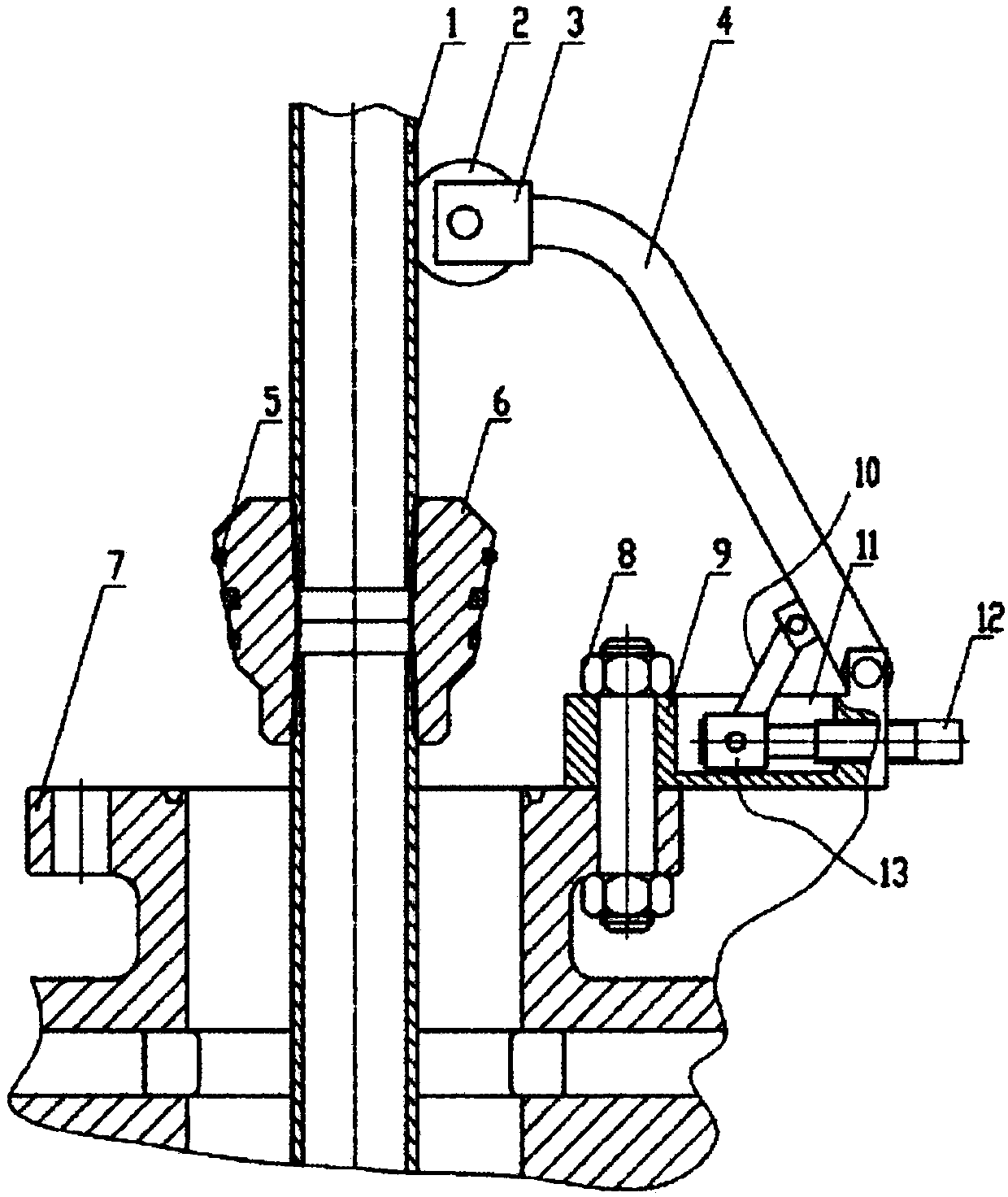

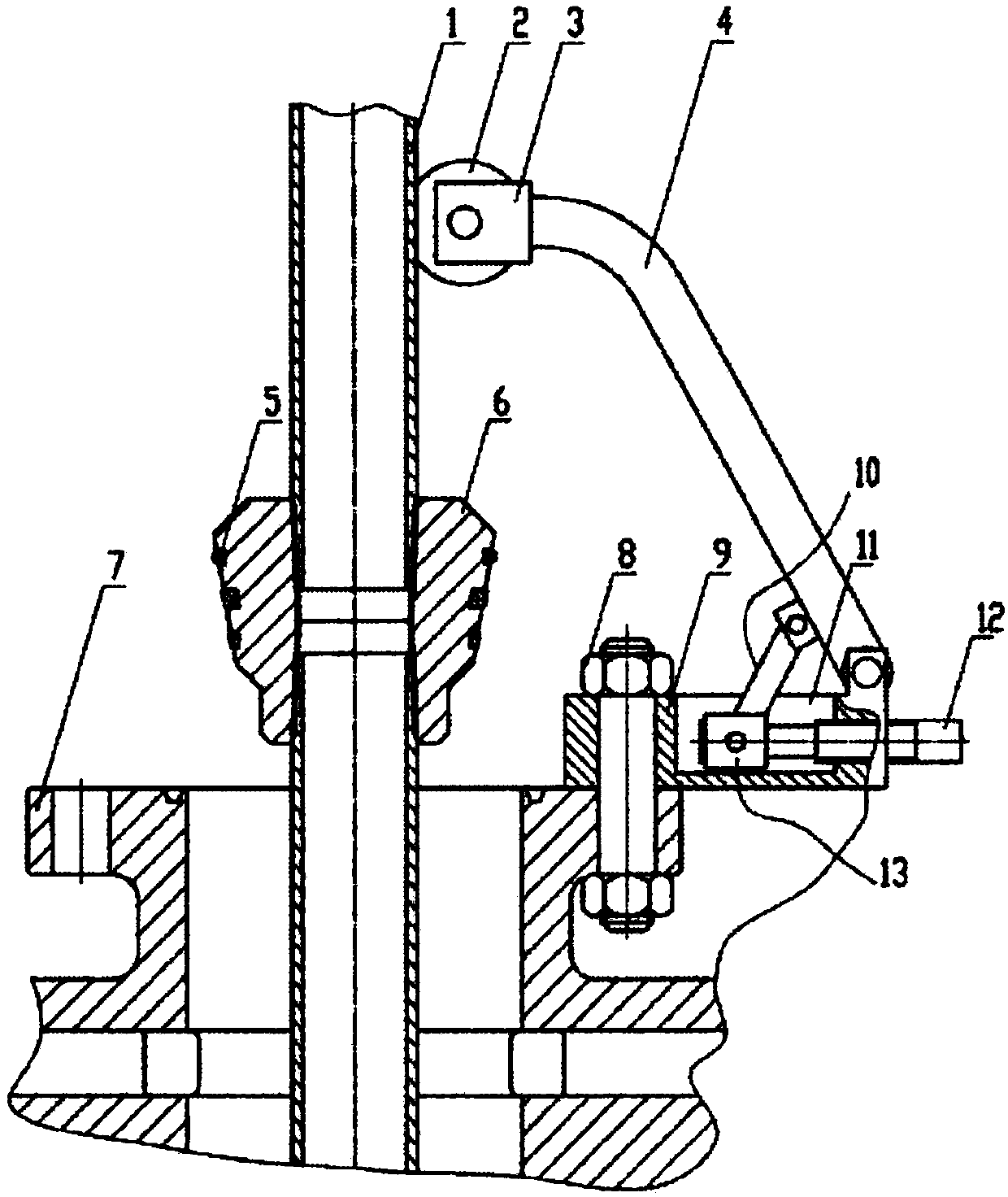

[0011] see figure 1 , including lifting oil pipe 1, roller 2, wheel frame 3, bracket 4, seal ring 5, hanger 6, blowout preventer 7, connecting bolt 8, base 9, support rod 10, adjusting screw 11, support seat 13, seal ring 5 is installed on the hanger 6, the lower part of the lifting oil pipe 1 is connected with the hanger 6, the oil pipe in the well is connected under the hanger 6 and passes through the blowout preventer 7, the base 9 is fixed on the blowout preventer 7 by the connecting bolt 8, the base 9 There is a track groove 11, and there is a screw hole on the right side of the base 9. The internal thread of the screw hole is matched with the external thread of the adjusting screw 12, and the adjusting screw 12 passes through the screw hole on the right side of the base 9 and enters the track groove 11. , the support base 13 is sleeved on the left end of the adjusting screw rod 12, the support base 13 is in the track groove 11, the support base 13 can only walk and canno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com