Construction method of high pressure jet expansion head anchor rod and its device

A technology of high-pressure spraying and construction method, applied in the direction of infrastructure engineering, construction, sheet pile wall, etc., can solve the problems of complicated operation, increased construction equipment, difficult construction, etc., and achieve the effect of reducing cost and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

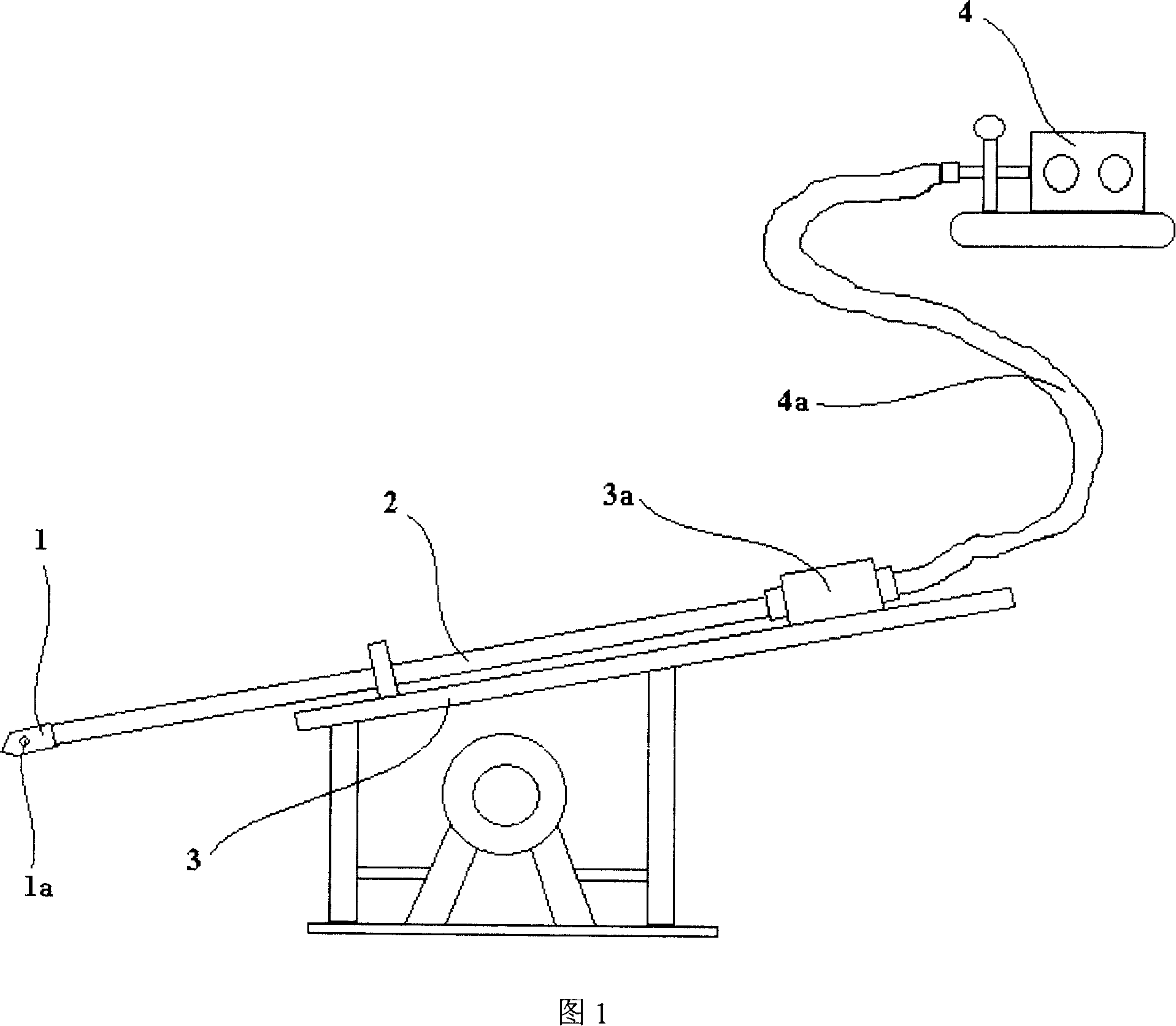

[0040]Embodiment 1. A construction device for a high-pressure injection expanding head bolt, in conjunction with FIG. 1 , includes a nozzle 1, a high-pressure pipe 2, a drilling rig 3 and a high-pressure pump 4. The nozzle 1 is provided with a radial nozzle 1a, and the nozzle is installed on the The front end of the high-pressure pipe 2 communicates with the high-pressure pump 4 connected to the rear end of the high-pressure pipe 2 through the hollow channel of the high-pressure pipe. Control the high pressure pipe 2 to operate.

[0041] The spray head can be a hollow columnar, conical or hemispherical object, and one end has a joint that is adapted and communicated with the high-pressure pipe, generally speaking, it can be threaded. There are one or two nozzles on the nozzle, and the nozzles are preferably arranged radially or radially symmetrically in a normal plane of the nozzle. The nozzle is a small hole distributed on the side wall of the nozzle, with a diameter of 0.5-...

Embodiment 2

[0044] Embodiment 2. A construction method of a high-pressure injection expanding head bolt. Its basic process steps are:

[0045] Drilling: Use a drilling rig to drill to the designed depth to form anchor holes. This step can be drilled with a drill pipe equipped with a drill bit, or a casing with a casing drill bit installed. After the anchor hole is formed, the casing is withdrawn by an appropriate distance to leave a place for setting the expansion head. The casing drill bit can be a circular drill bit with a diameter equivalent to the casing pipe, or it can be formed by welding several alloy blades on the periphery of the front end of the casing pipe. The drilling rig for controlling casing drilling can be either a common drilling rig or a dual power head drilling rig.

[0046] Reaming: Use a drilling rig to control the high-pressure pipe, put the nozzle installed at the front end of the high-pressure pipe into the anchor hole where the expansion head is to be set, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com