A two-phase temperature-responsive phase-change fracturing fluid system

A phase change fracturing, temperature response technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as fractures without flow channel conductivity, phase change materials entering natural fractures, etc., and achieve broad market application Prospects and the effect of ensuring the success of the construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

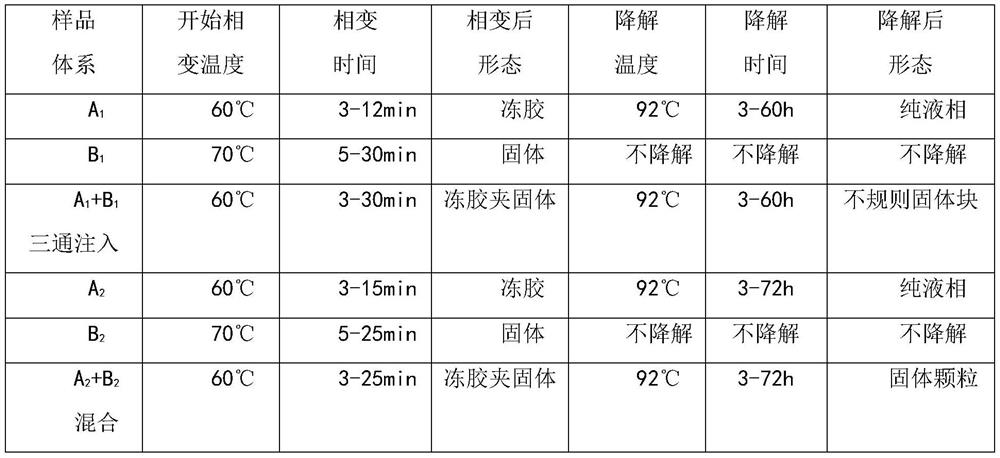

Embodiment 1

[0019] Phase change fracturing fluid system 1, 50% non-phase change system A 1 , 50% phase change system B 1 , the ground is prepared separately, during construction, A 1 with B 1 In the wellbore 1:1 mixed injection formation, A 1 It consists of 10% gelling agent+2% regulator, and the rest is water; B 1 The composition is 70% monomer + 1.5% crosslinking agent + 1% dispersant, and the rest is water.

[0020] A 1 The specific composition is: 8% N-methyl-D-glucosamine hydrochloride + 2% carboxymethyl chitosan + 0.5% NH 4 Cl+1% formaldehyde+0.5% ethylenediamine, the rest is water.

[0021] per 100g A 1 Preparation process: Measure 88g of water, then slowly add 8g of N-methyl-D-glucosamine hydrochloride, 2g of carboxymethyl chitosan, 0.5g of NH 4 Cl, 1g of hexamethylenetetramine, 0.5g of ethylenediamine, the preparation is complete until the mixture is evenly stirred.

[0022] B 1The specific composition is: 30% styrene + 30% divinylbenzene + 10% methyl methacrylate + 1% ...

Embodiment 2

[0025] Phase change fracturing fluid system 2, 55% non-phase change system A 2 , 45% phase change system B 2 , the ground first prepared A 2 , B 2 After that, put A 2 , B 2 Mix well and inject into the ground. A 2 It consists of 15% gelling agent+3% regulator, and the rest is water; B 2 The composition is 60% monomer + 1.5% crosslinking agent + 1% dispersant, and the rest is water.

[0026] A 2 The specific composition is: 5% glucosamine hydrochloride + 5% N-methyl-D-glucosamine hydrochloride + 3% carboxymethyl chitosan + 2% chitosan + 0.5% citric acid + 1% acetamide + 1% glutaraldehyde + 0.5% trimethyl phosphate, the rest is water.

[0027] per 100g A 2 Preparation process: Measure 82g of water, then slowly add 5g of glucosamine hydrochloride, 5g of N-methyl-D-glucosamine hydrochloride, 3g of carboxymethyl chitosan, 2g of chitosan while stirring , 0.5g of citric acid, 1g of acetamide, 1g of glutaraldehyde, 0.5g of trimethyl phosphate, and the preparation is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com