An equipment damage detection and risk management method

A technology of risk management and special equipment, applied in the field of failure analysis of special equipment, can solve problems such as uneven analysis quality, failure to obtain material safety application evaluation, and hinder technology improvement, so as to achieve the effect of maintaining effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

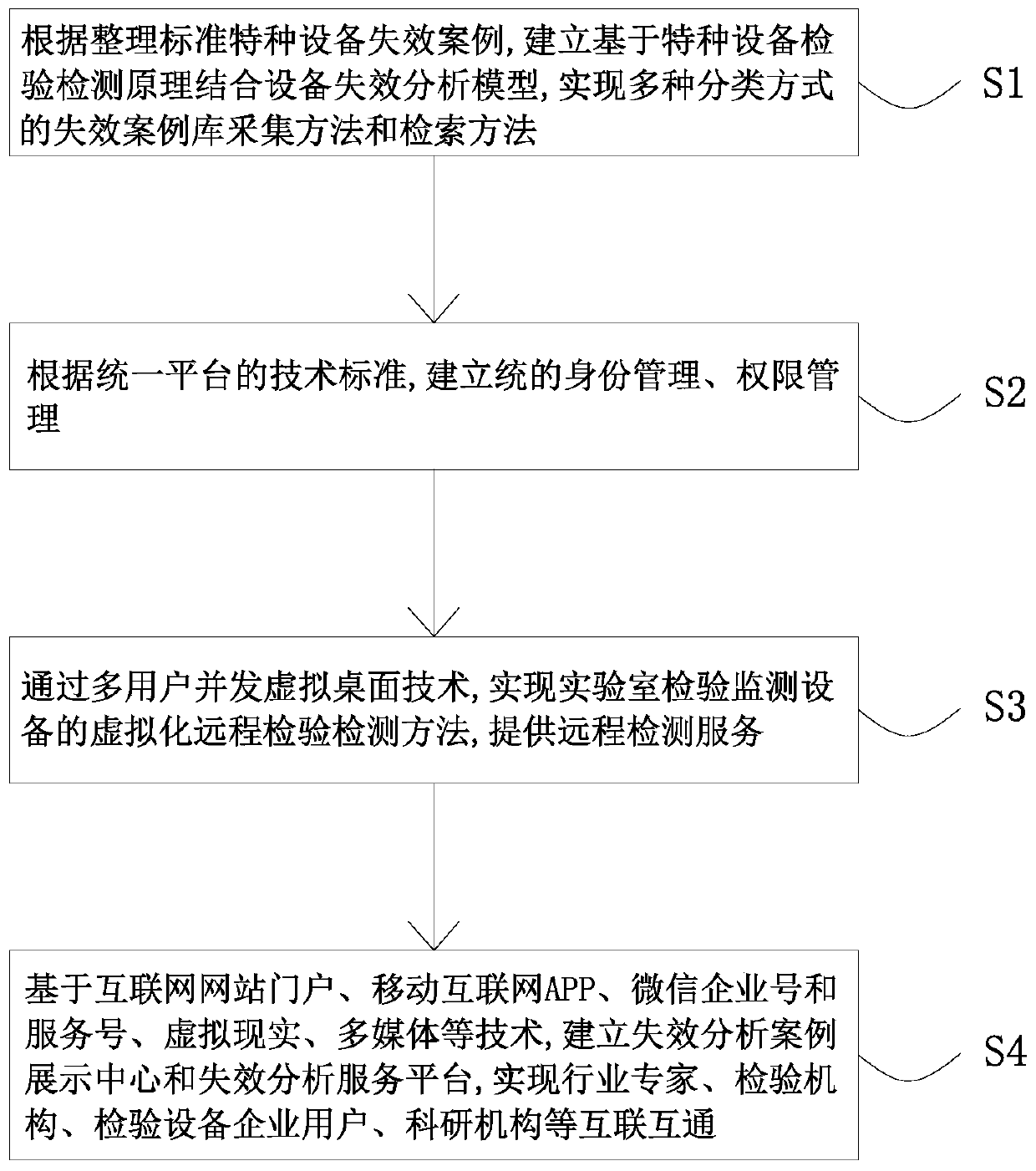

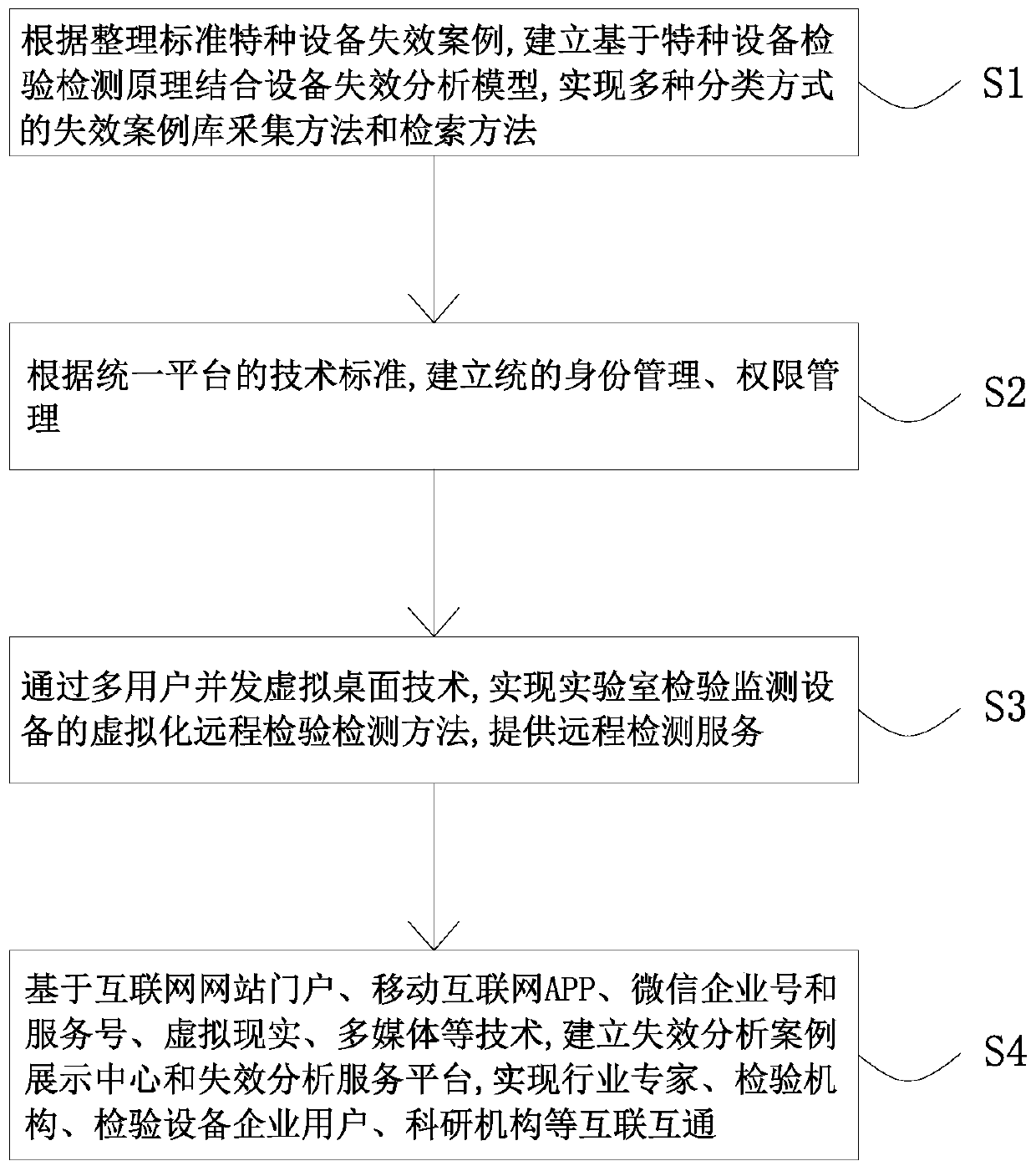

[0026] According to the first aspect of the present invention, the present invention provides a method for equipment damage detection and risk management, such as figure 1 shown, including the following steps:

[0027] S1: According to the standard special equipment failure cases, establish a failure analysis model based on special equipment inspection and detection principles combined with equipment failure analysis, realize multiple classification methods of failure case library collection methods and retrieval methods, establish a case library, and complete the collection and arrangement of 160 failure analysis cases And sharing, the "snowball" mode of the case will be added through the network sharing mode. According to the steps in S1, the special equipment injury monitoring and risk management case library will be completed, and the failure analysis case resource collection of case network platform sharing and case physical sample sharing will be realized. , it is requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com