T row tilting prevention device and T row tilting prevention method

A technology of anti-falling and position-limiting devices, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of time-consuming, easy to fall, and damage the surface of T row, etc., to increase the overall stability and shape And the effect of stable placement and simple materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following, the present invention will be more clearly and completely described by means of preferred embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

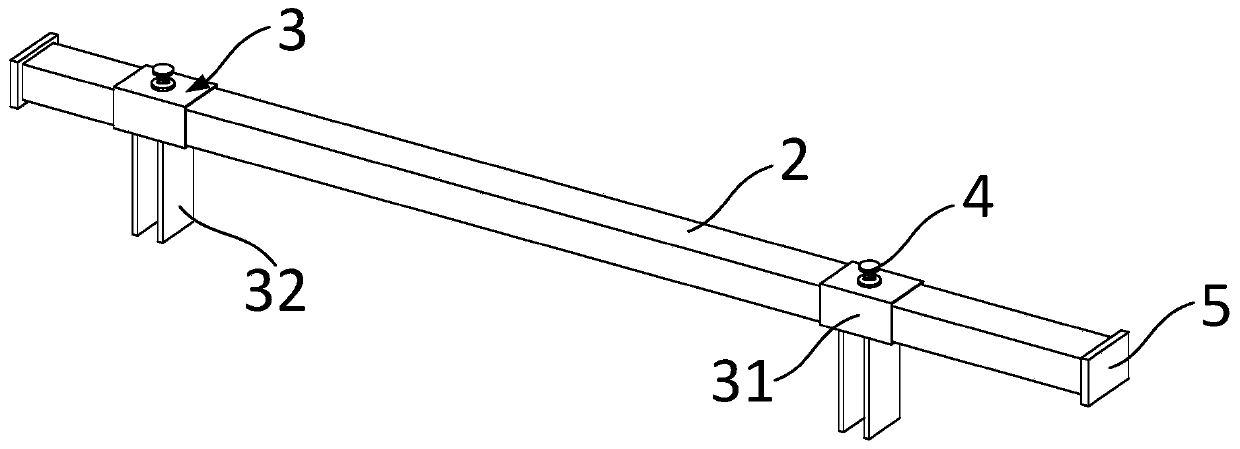

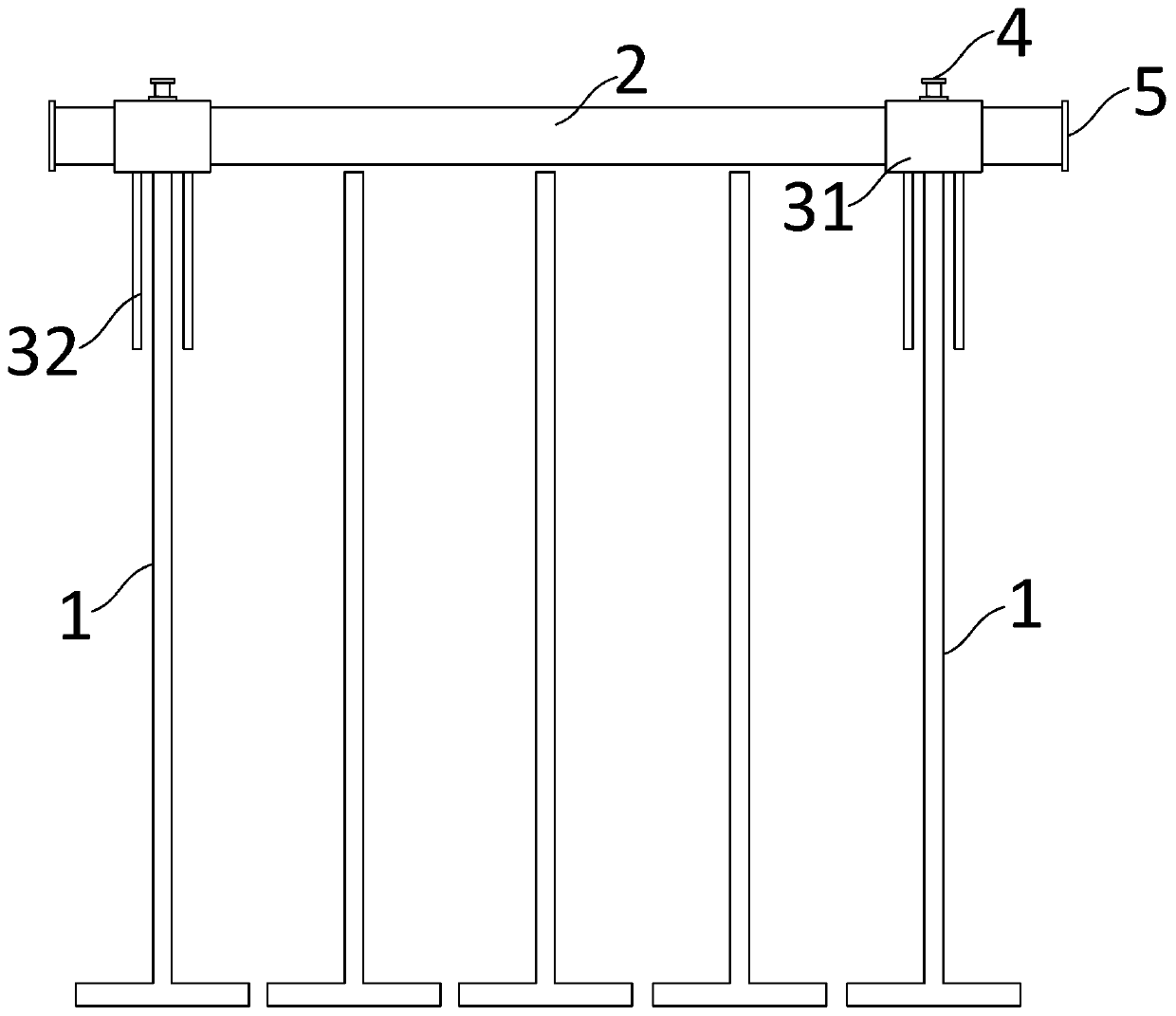

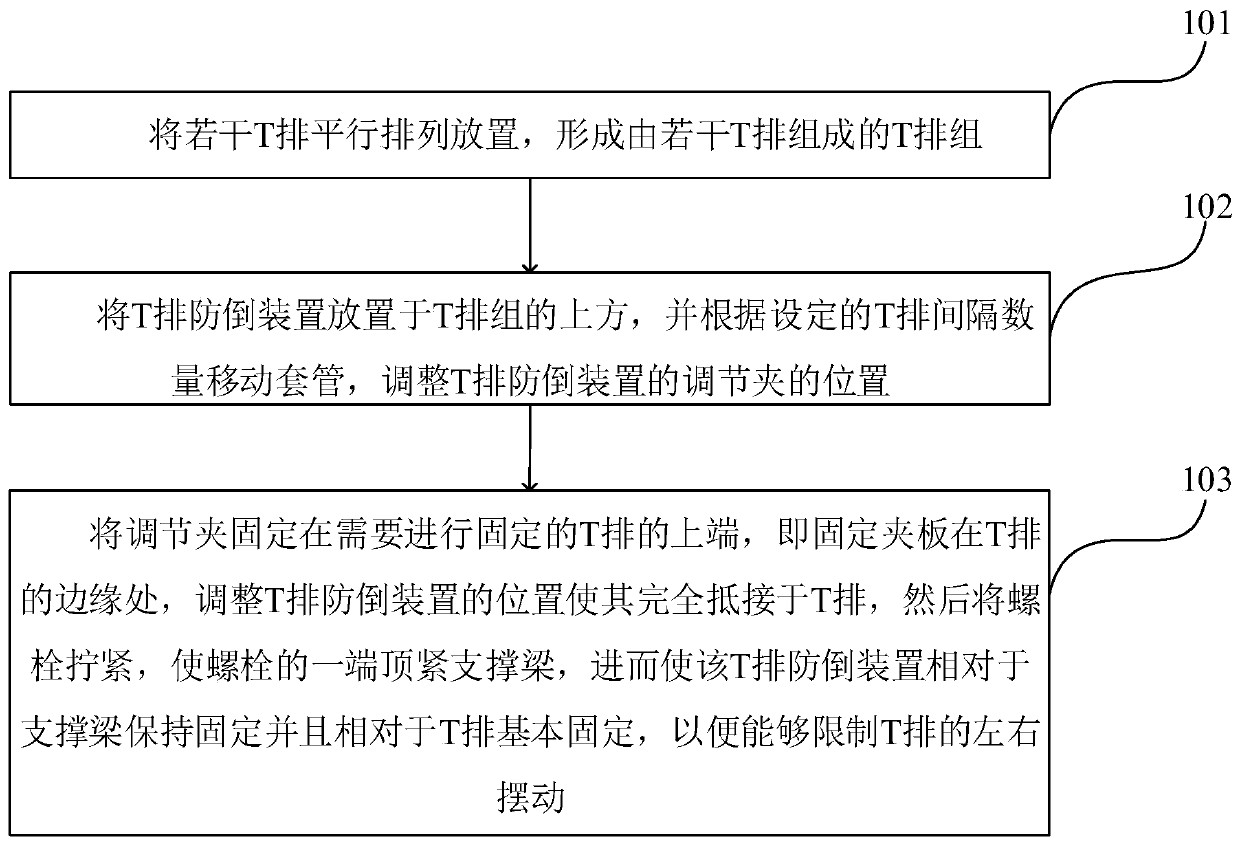

[0034] Such as figure 1 and figure 2 As shown, the present invention provides a T row anti-falling device, which includes a support beam 2 and at least two adjustment clips 3, the adjustment clip 3 is sleeved on the support beam 2, and at least one adjustment clip 3 can be placed on the support beam 2 Move along the axis. In this embodiment, two adjusting clips 3 are provided, and the two adjusting clips 3 can move along the axial direction of the support beam 2 . In order to achieve a better effect of stabilizing the T row 1 , more than two adjusting clips 3 can also be used. The adjusting clip 3 includes a sleeve 31 and a splint 32 . The splint 32 is arranged on the outer wall of the sleeve 31 for fixing the adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com