Split type buffering mechanism used for coupler buffers

A buffer mechanism and split-type technology, applied in buffers, railway car body parts, transportation and packaging, etc., can solve the problems of large wheel set lateral force, excessive structure, truck derailment, etc., to reduce wheel set lateral force, High positional stability, the effect of avoiding derailment of trucks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

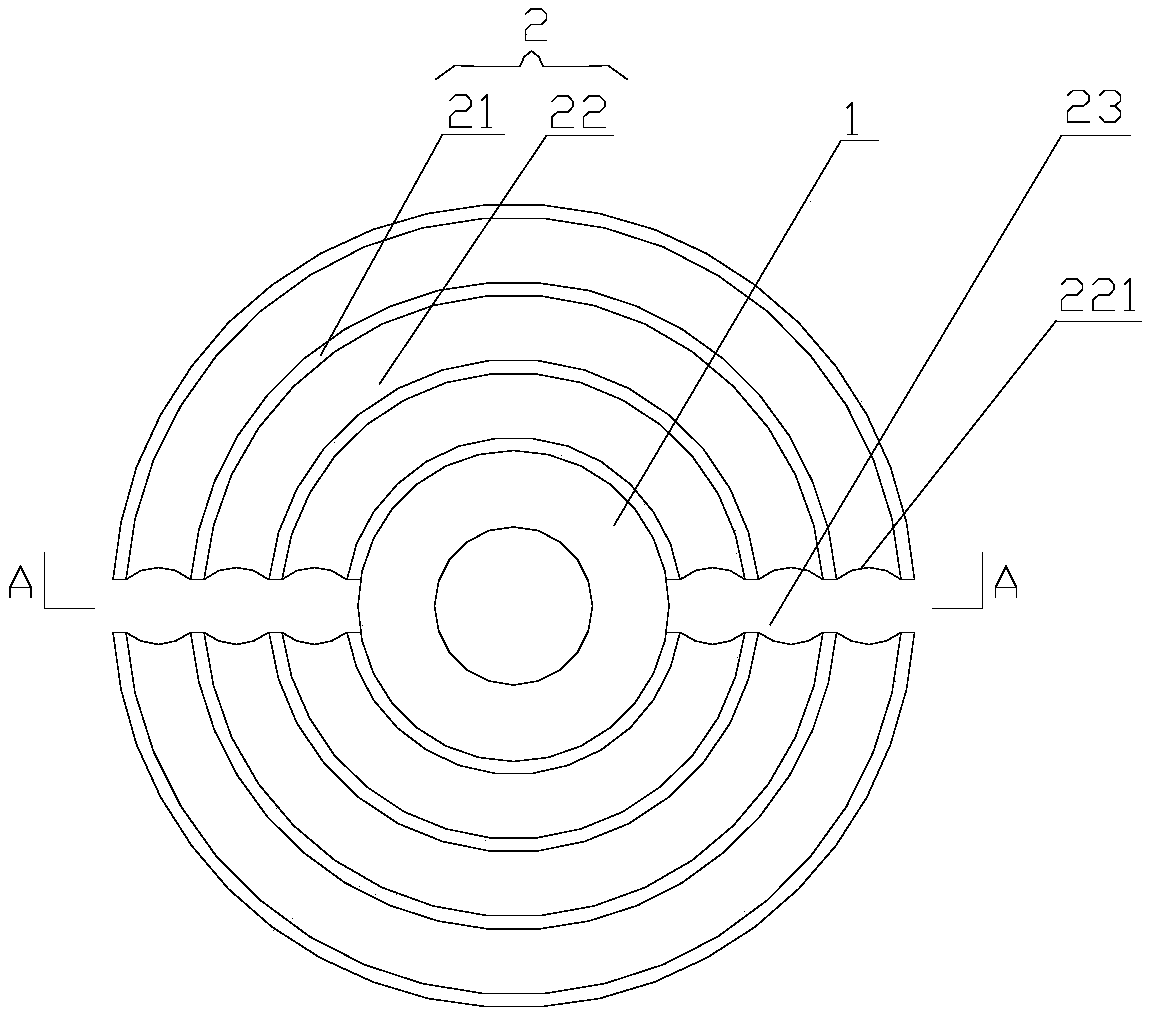

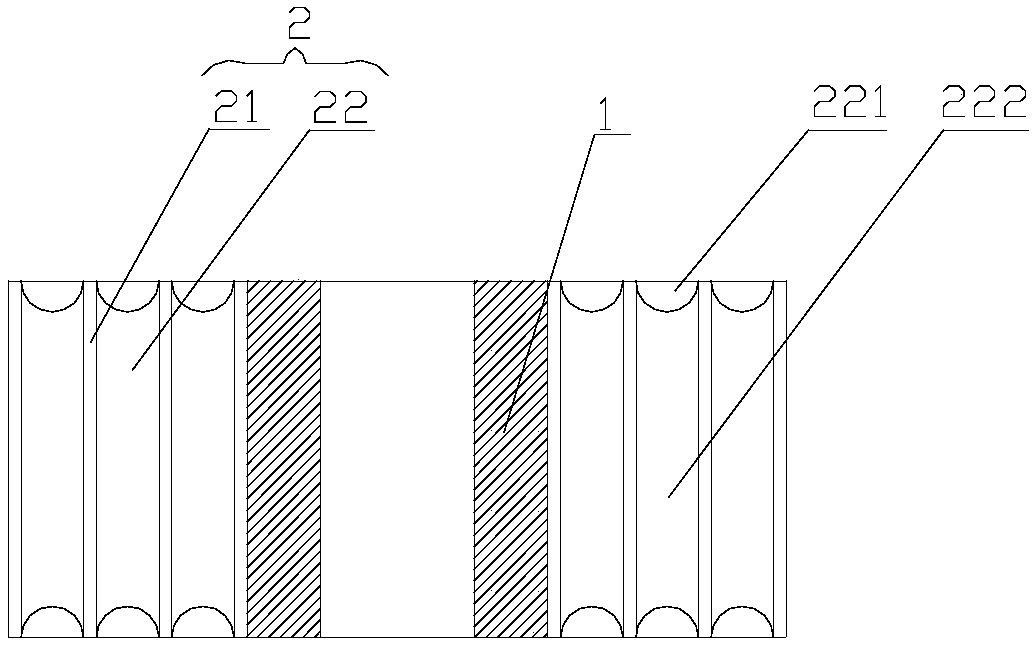

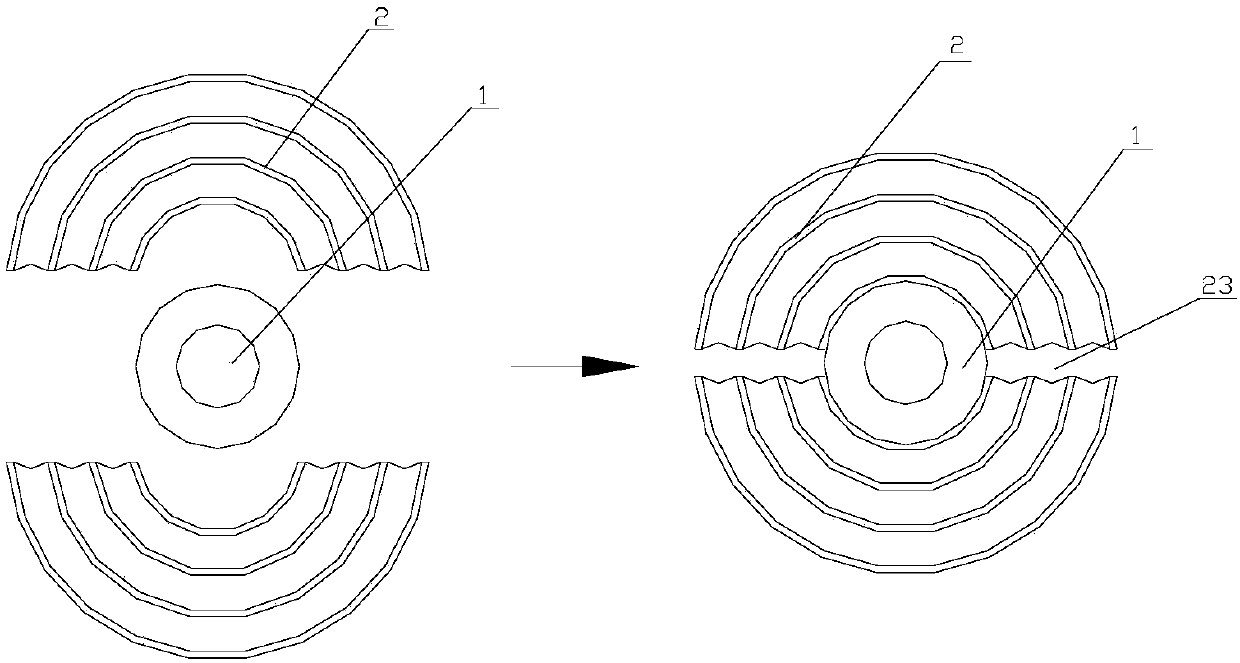

[0029] Such as Figure 1 to Figure 3 As shown, the split-type buffer mechanism for the coupler buffer of this embodiment includes an inner core 1 in the middle and two buffer units 2 arranged symmetrically along the inner core 1. On the other hand, the inner core 1 is a ring structure, and the buffer unit 2 is composed of several arc-shaped metal partitions 21 and several arc-shaped elastic bodies 22 arranged in a cross arrangement.

[0030] In this embodiment, the thickness of the elastic body 22 is not less than twice the thickness of the metal separator 21 .

[0031] In this embodiment, the elastic body 22 is a rubber structure, and the elastic body 22 is fixedly connected with the metal separator 21 by vulcanization bonding.

[0032] In this embodiment, there are three metal separators 21 and three elastic bodies 22 .

[0033] In this embodiment, both ends of the elastic body 22 are provided with arc-shaped grooves A221 , and the width of the arc-shaped grooves A221 is e...

Embodiment 2

[0038] Such as image 3 As shown, the difference between this embodiment and the first embodiment is that: the metal partition 21 and the elastic body 22 are connected in a horizontal stacking manner, and the outermost metal partition 21 is provided with a metal jacket for fastening 3, all the other are with embodiment 1.

[0039] The working principle of the above-mentioned embodiment is: when the vehicle is in a stopped state, the buffer structure 2 is in a free state, and the surroundings of the inner core 1 are not compressed; The elastic body 212 on the right side is in a compressed state, and the elastic body 212 on the left side of the inner core 1 is in a free state; when the vehicle is in a braking deceleration state, the buffer structure 2 is compressed to the left, and the elastic body 212 on the left side of the inner core 1 is in a compressed state , the elastic body 212 on the right side of the inner core 1 is in a free state, and the elastic body 212 on the lef...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap