A dimension inspection tool for workpieces with irregular shapes

A technology for irregular workpieces, applied in the field of irregular-shaped workpiece size inspection tools, can solve problems such as positioning and detection difficulties, and outer contour size detection, and achieve cheapness and accuracy, high degree of automation, and simple positioning steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

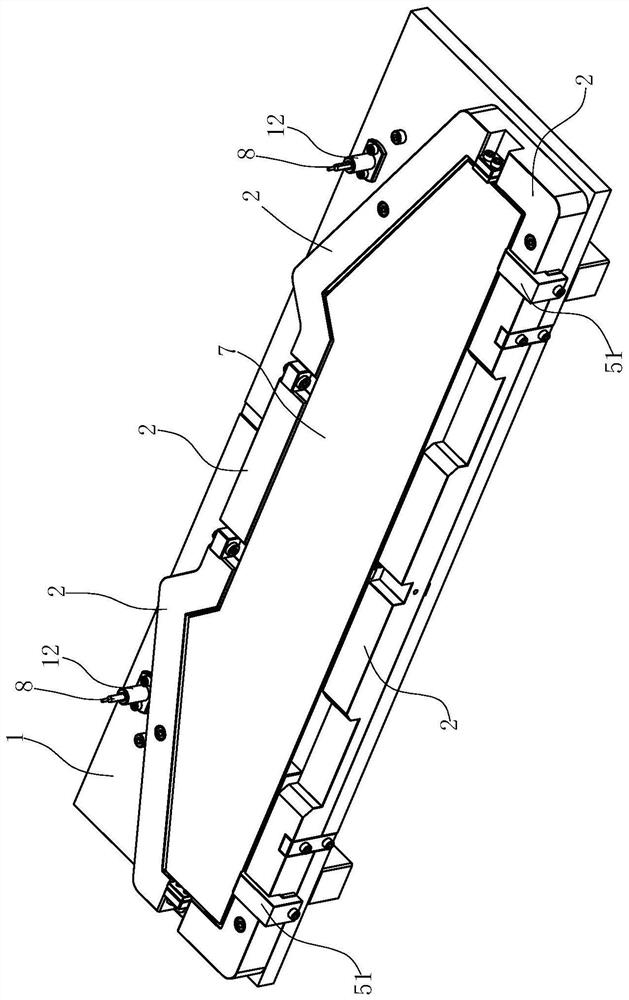

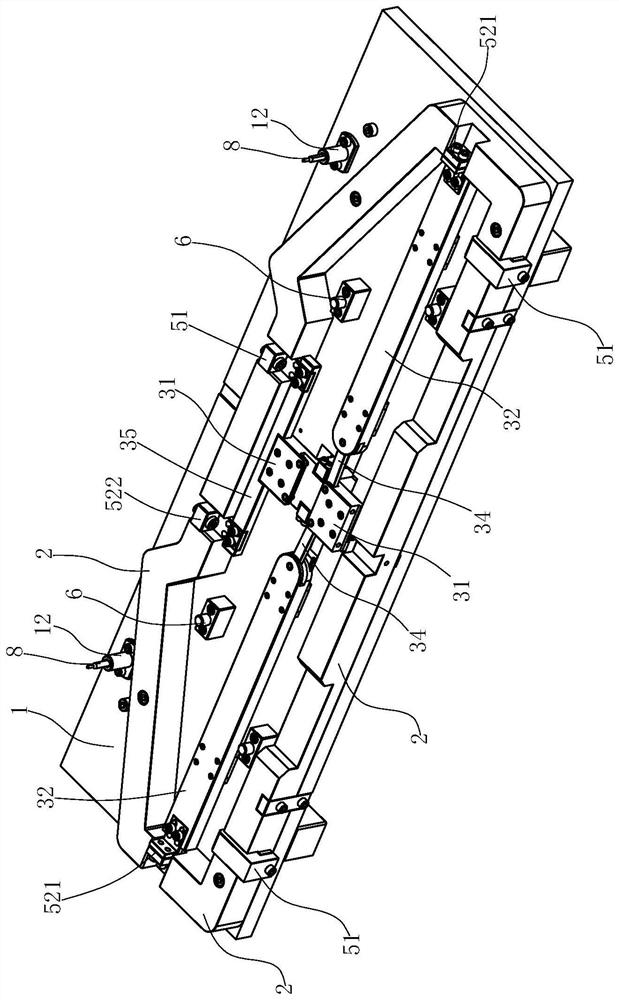

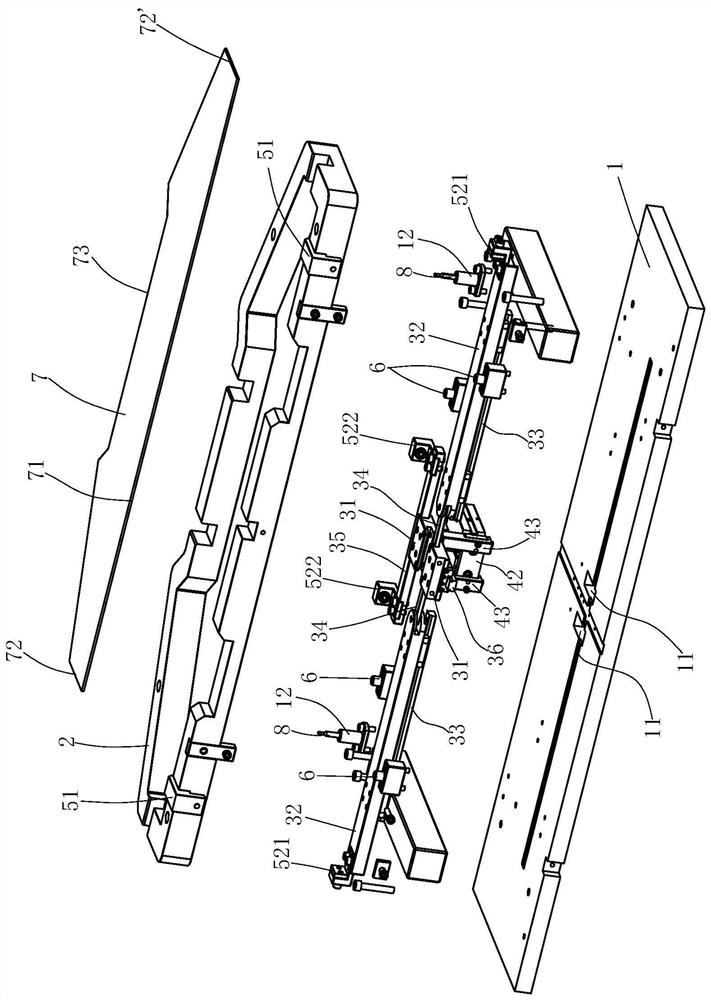

[0027] Such as Figure 1 to Figure 3 The irregular-shaped workpiece size inspection tool shown includes:

[0028] The bottom plate 1 is the installation base of the entire inspection tool, and the middle part of the bottom plate 1 is provided with a slide hole 11 .

[0029] A socket 12 for placing the go-no-go gauge 8 is also provided on the base plate 1 .

[0030] The inspection body 2 is arranged on the bottom plate 1, adapted to the shape of the workpiece 7 to be inspected, and serves as a benchmark for comparing the size of the workpiece 7 to be inspected. The inspection body 2 is provided with a positioning member 51 for positioning the first side 71 of the workpiece to be inspected; the positioning member 51 in this embodiment is a plurality of positioning blocks arranged at intervals.

[0031] The positioning assembly is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com