Vehicle hydraulic cylinder rear-tilting-type mechanical floating assembly

A hydraulic cylinder, tilt-back technology, applied in vehicle parts, transportation and packaging, superstructure of trucks, etc., can solve problems such as repeated swings, prolong service life, avoid hydraulic cylinder damage or oil leakage, and facilitate The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

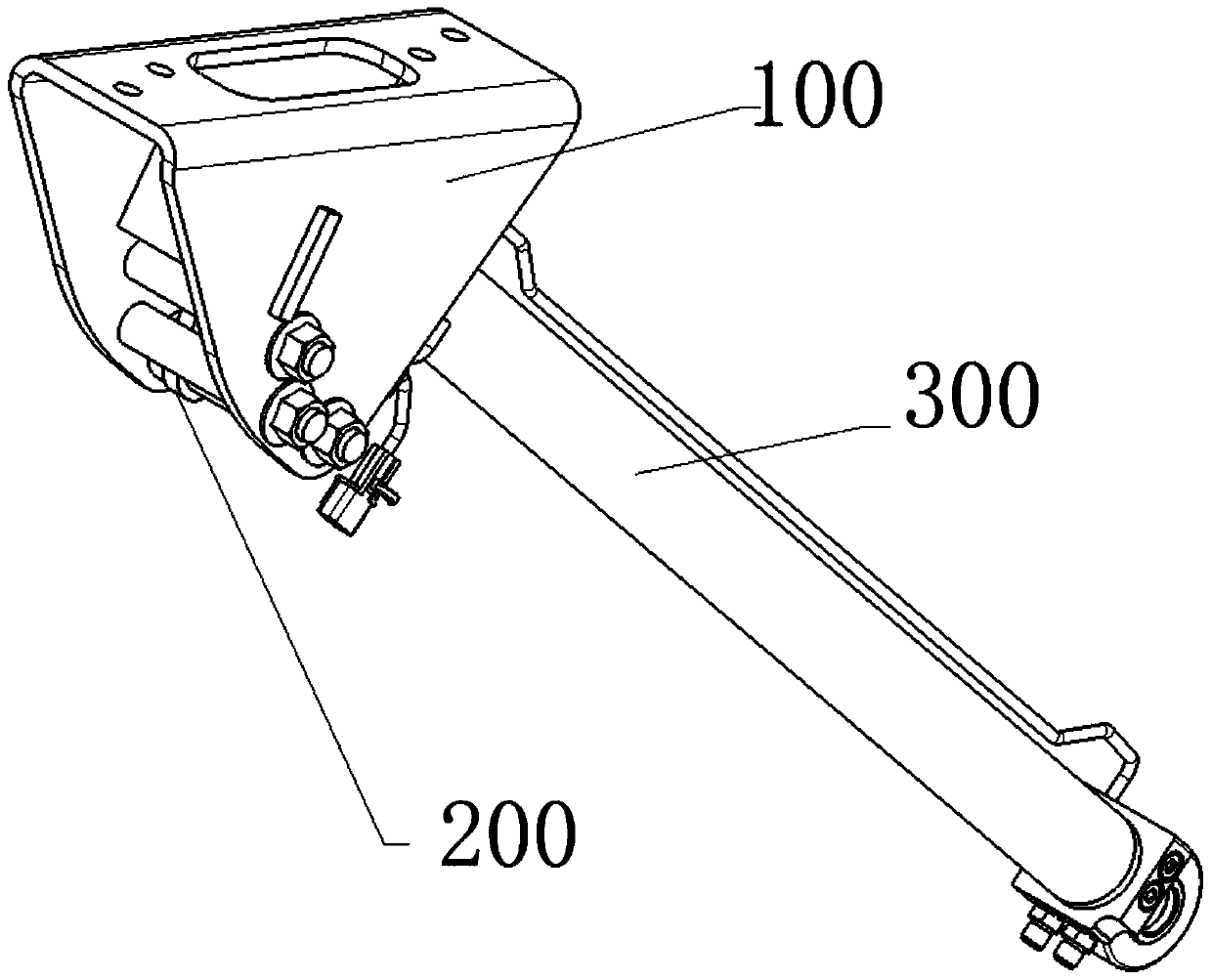

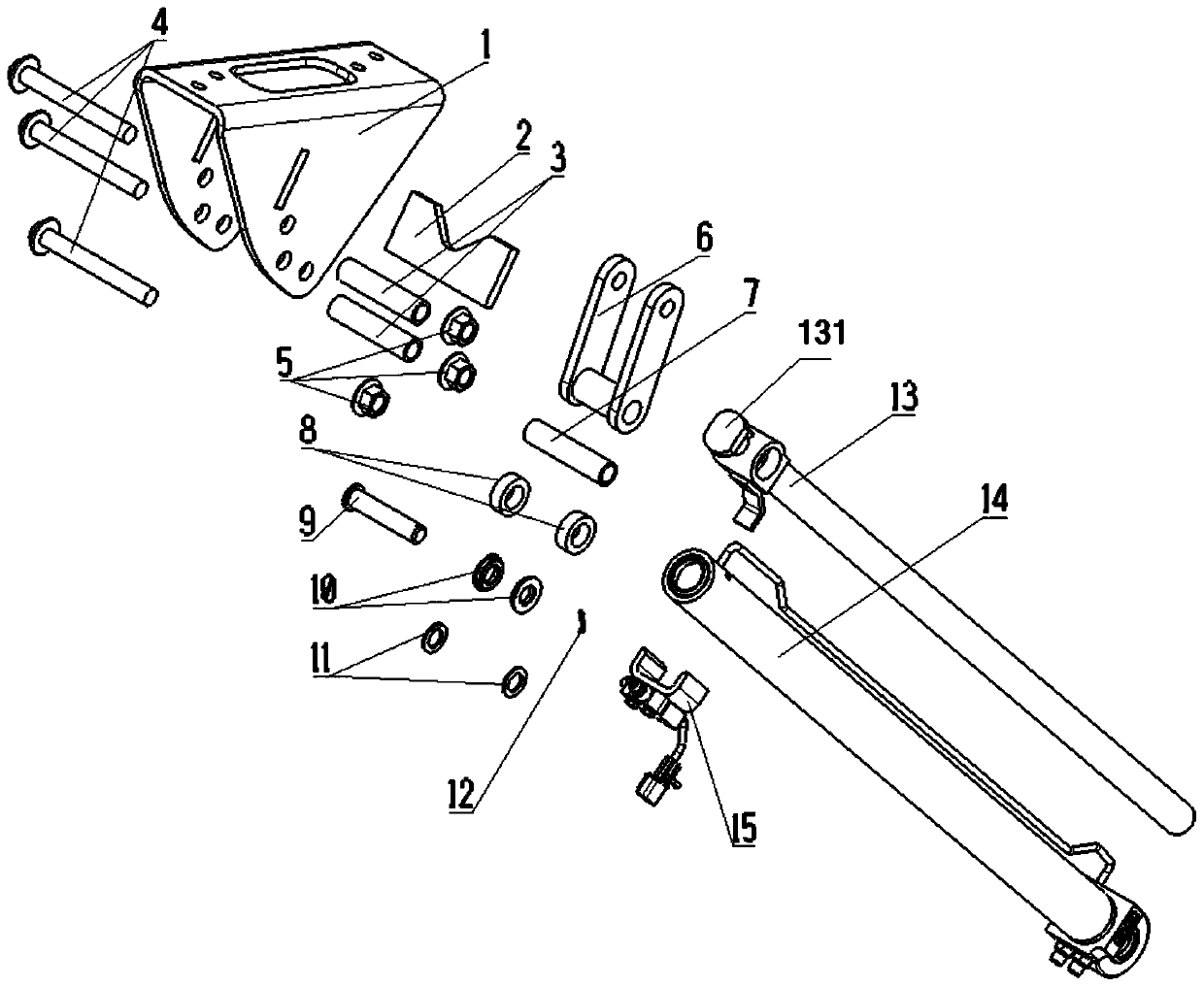

[0027] as attached figure 1 and figure 2 As shown, in this embodiment 1, a vehicle hydraulic cylinder backward tilting mechanical floating assembly assembly includes a bracket assembly 100, a swing arm assembly 200 and a hydraulic cylinder assembly 300, and the bracket assembly 100 and the swing arm The assembly 200 is rotatably connected, and the swing arm assembly 200 is rotatably connected to the hydraulic cylinder assembly 300;

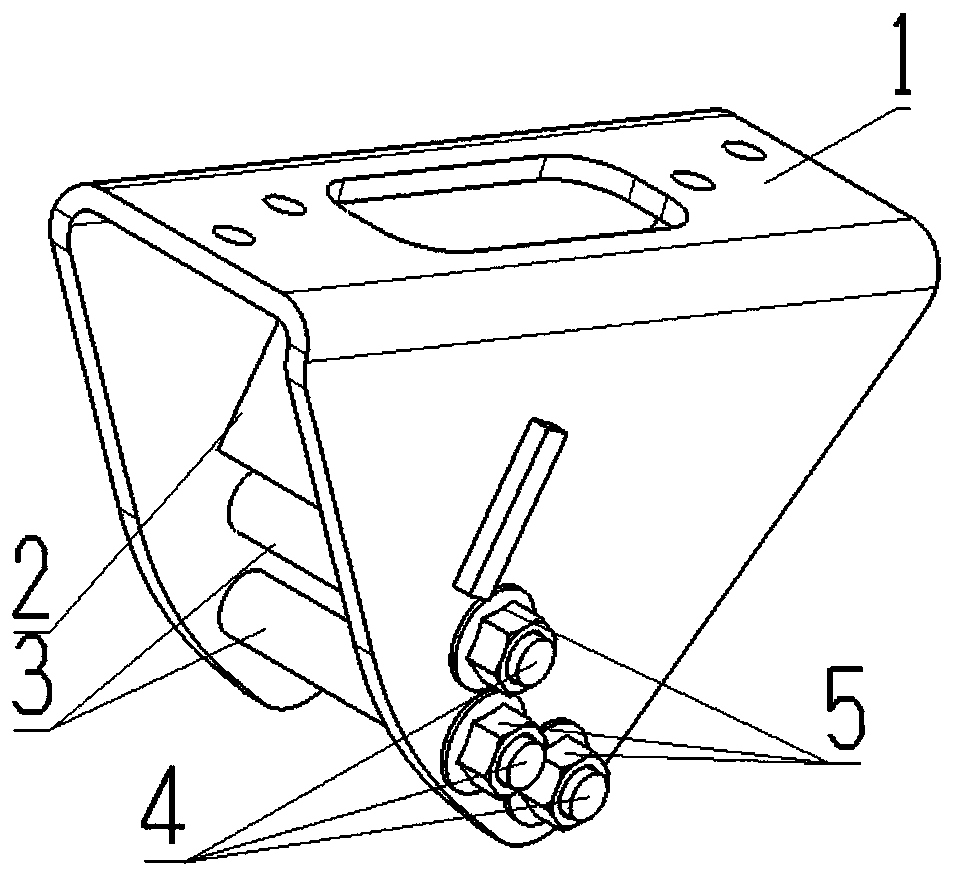

[0028] Such as image 3 As shown, the bracket assembly 100 includes a bracket 1, a turn-over limit block 2, two limit sleeves 3, three bolts 4 and three nuts 5, and the two ends of the turn-over limit block 2 are welded on the bracket 1 In the positioning slots on both sides, two bolts 4 pass through the through holes on the bracket 1 respectively, are inserted into the limit sleeve 3, and are fastened by nuts 5, and the bracket 1 and the swing arm assembly 200 pass through another The bolt 4 is connected, and the upper end of the bracket 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com