Substation secondary equipment intelligent control system

A technology for secondary equipment and control systems, applied in information technology support systems, electrical components, circuit devices, etc., can solve the problems of reduced reliability of protection devices, impact of plug-in performance, failure to obtain fault recording and fault information of protection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

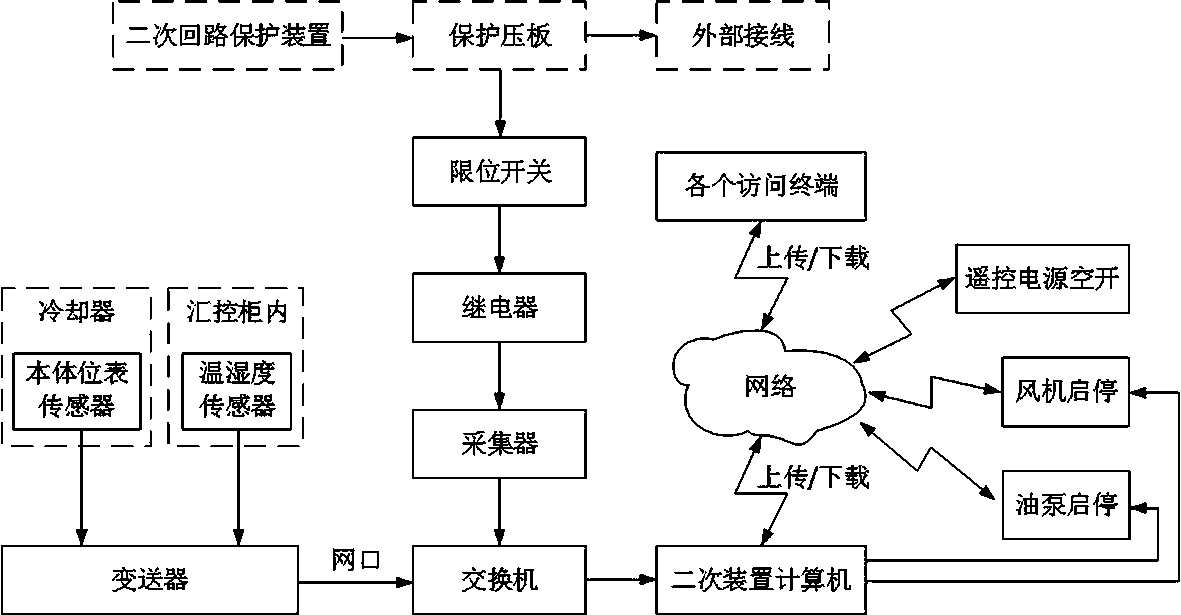

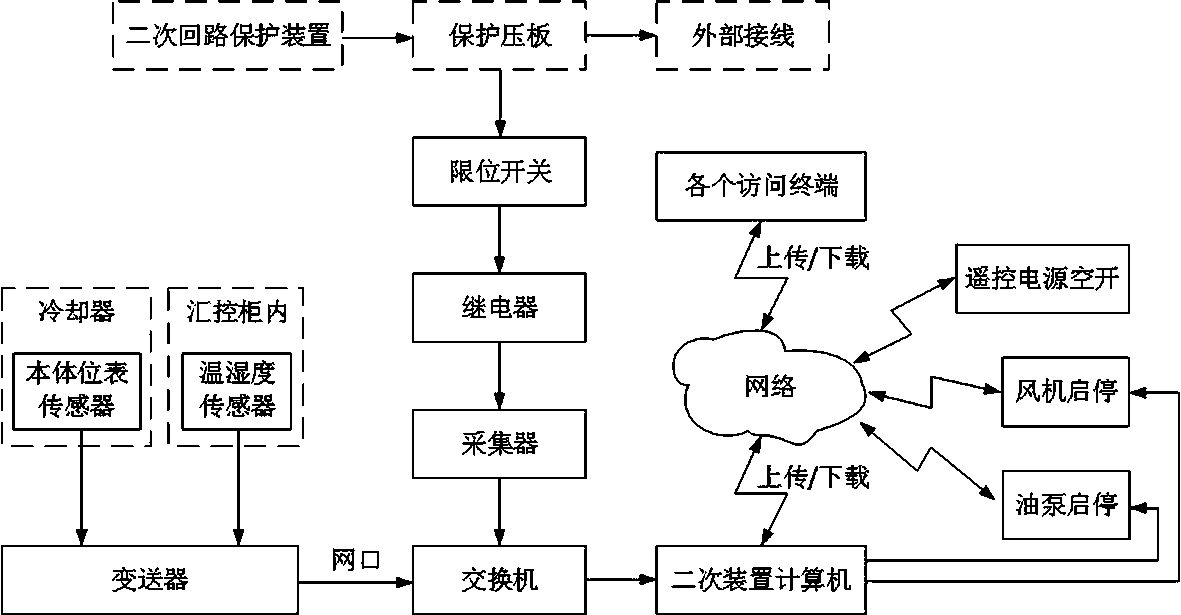

[0027] In order to make the object, technical scheme and advantages of the present invention clearer, the following in conjunction with the attached figure 1 and specific examples to clearly and completely describe the invention.

[0028] Such as figure 1 As shown, this embodiment relates to an intelligent management and control system for substation secondary equipment. The temperature and humidity sensor inside; the circuit where the limit switch is located has a relay coil in series, and the relay contacts are connected in series on the input end of the collector, and the output signal of the collector is sent to the secondary device computer through the switch, so The output signals of the body position meter sensor and the temperature and humidity sensor are sent to the secondary device computer through the transmitter and the switch in sequence, and the secondary device computer is connected to the network through the network port.

[0029] Further, the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com