Exploder eliminating vehicle and exploder eliminating method

A vehicle body and hydraulic rod technology, applied in the field of dangerous goods handling equipment, can solve problems such as poor environmental applicability, low efficiency, and poor safety, and achieve the effects of improving protection capability, ensuring safety, and improving removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

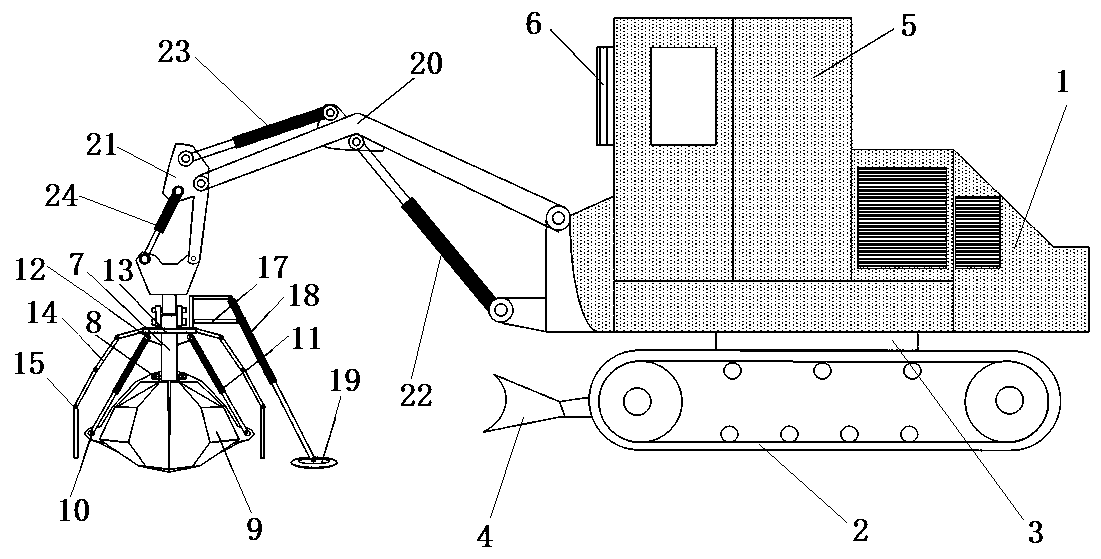

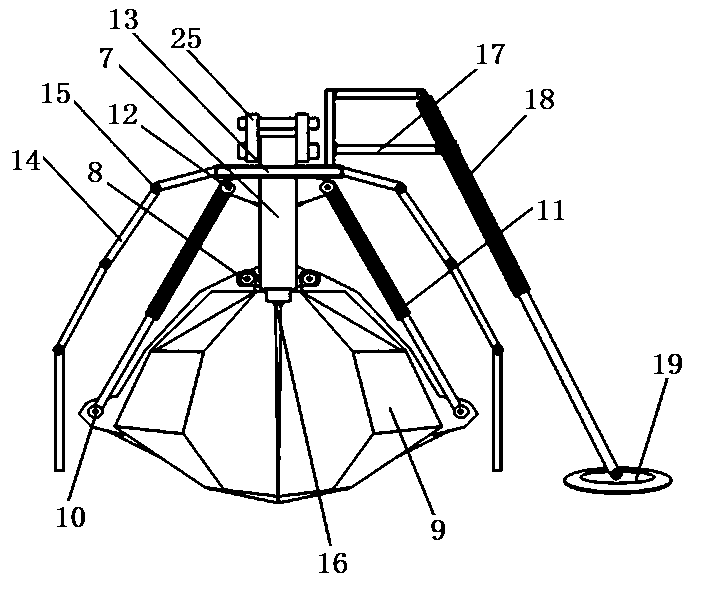

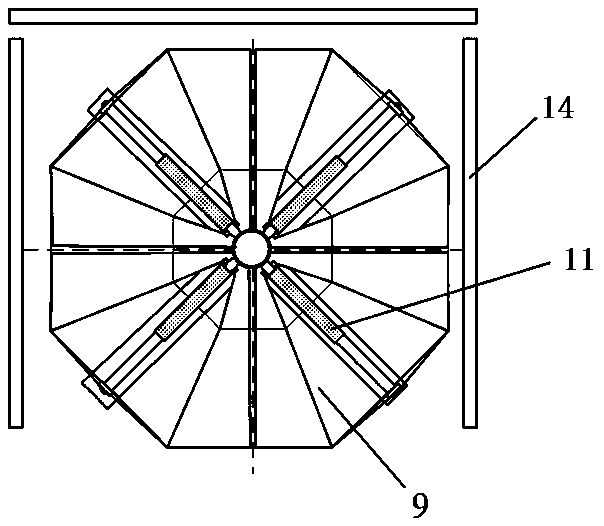

[0024] Such as Figure 1 to Figure 3 As shown, the EOD vehicle of the present invention includes a car body 1 and an EOD grab bucket arranged in front of the car body. The chassis of the car body is a crawler walking device 2, and a revolving device is provided between the car body 1 and the crawler walking device 2. The device 3 is provided with a flat blade 4 at the front end of the crawler walking device 3. The car body 1 is equipped with a cockpit 5. The fuel tank and engine of the car body 1 and the front, rear and both sides of the cockpit are respectively equipped with explosion-proof shields. The explosion-proof shields are metal steel plates with a certain thickness (about 1.6cm). In order to improve the cockpit 5’s ability to defend against unexploded ordnance fragments and shock waves, an explosion-proof window 6 is provided at the front end of the cockpit 5. The explosion-proof window 6 is composed of multiple explosion-proof glass, and the cockpit 5 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com