Anti-peeping film

A technology of anti-spy film and anti-spy layer, applied in the field of optics, can solve the problems of low light transmittance of anti-spy film, achieve good anti-spy effect, good light transmittance, and improve visual experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

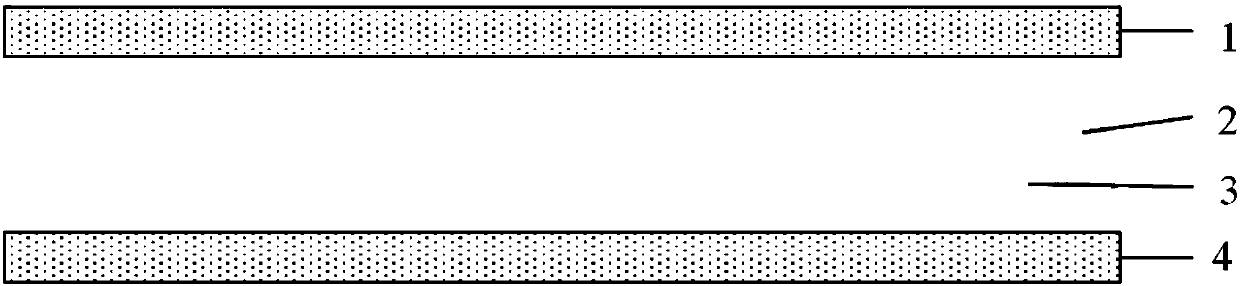

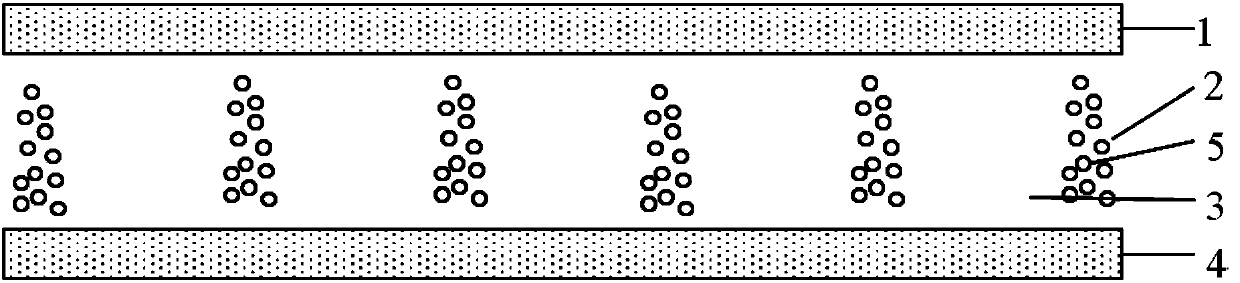

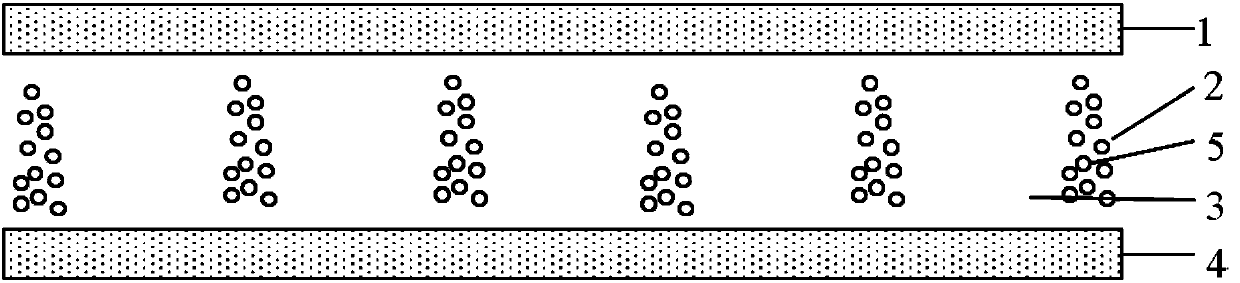

[0045] The invention provides an anti-peeping film. The anti-peeping film includes an upper supporting layer, an anti-peeping layer and a lower supporting layer in sequence. The anti-peeping layer includes a diffusion unit and a light-transmitting unit, and the light-transmitting unit is filled in the diffusion unit. Between, the diffusion unit includes light diffusion particles.

[0046] The content of the light-diffusing particles in the privacy-preventing layer is 1%, and the content is percentage by weight.

[0047] The specific preparation method is as follows:

[0048] Mix PBMA (refractive index: 1.40) particles with an average particle size of 1 μm with UV-cured acrylic resin glue (refractive index: 1.70) at a mass ratio of 3:22, and stir with a high-speed disperser at a speed of 1000 rpm in the dark 60min to prepare the resin mixture for preparing the diffusion unit. Apply the resin mixture on the transparent PET surface (lower support layer) with polyurethane pre-co...

Embodiment 2

[0050] The anti-peeping film provided in Example 1. The content of light-diffusing particles in the anti-peeping layer is 30%.

[0051] Mix PBMA (refractive index: 1.48) particles with an average particle size of 1 μm with UV-cured acrylic resin glue (refractive index: 1.68) at a mass ratio of 3:22, and stir with a high-speed disperser at a speed of 1000 rpm in the dark 60min to prepare the resin mixture for preparing the diffusion unit. The resin mixture is coated on the surface of transparent PET with polyurethane pre-coating on one side, extruded by engraved rollers, and at a speed of 6-20m / min, reaching 450mj / cm 2 The energy high-pressure mercury lamp irradiates to make the diffusion unit solidify and form, and obtain the PET with the diffusion unit on the surface. Then apply UV-cured acrylic resin glue (refractive index: 1.68) on the surface of the diffusion unit, so that the acrylic resin glue completely fills the gap between the diffusion units, and then it is extrude...

Embodiment 3

[0053] The anti-peeping film provided in Example 1. The content of light diffusion particles in the anti-peeping layer is 10%.

[0054] Mix PBMA (refractive index: 1.48) particles with an average particle size of 2 μm with UV-cured acrylic resin glue (refractive index: 1.68) at a mass ratio of 3:22, and stir with a high-speed disperser at a speed of 1000 rpm in the dark 60min to prepare the resin mixture for preparing the diffusion unit. The resin mixture is coated on the surface of transparent PET with polyurethane pre-coating on one side, extruded by engraved rollers, and at a speed of 6-20m / min, reaching 450mj / cm 2 The energy high-pressure mercury lamp irradiates to make the diffusion unit solidify and form, and obtain the PET with the diffusion unit on the surface. Then apply UV-cured acrylic resin glue (refractive index: 1.68) on the surface of the diffusion unit, so that the acrylic resin glue completely fills the gap between the diffusion units, and then it is extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com