A method for handling fault mitigation in a vapour compression system

A technology of vapor compression and compressor, which is applied in the direction of climate sustainability, lighting and heating equipment, fluid circulation arrangement, etc., and can solve the problem of non-optimal operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

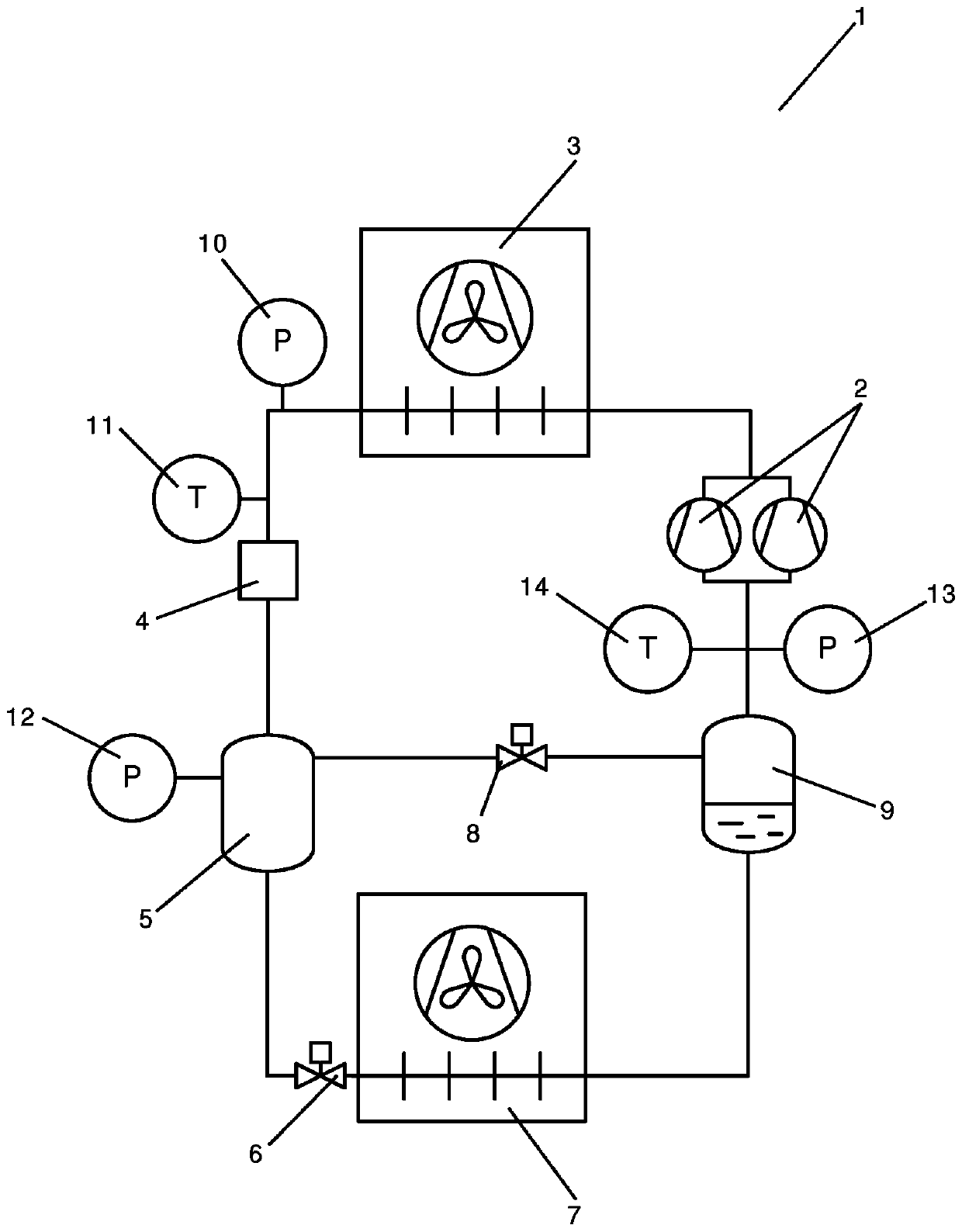

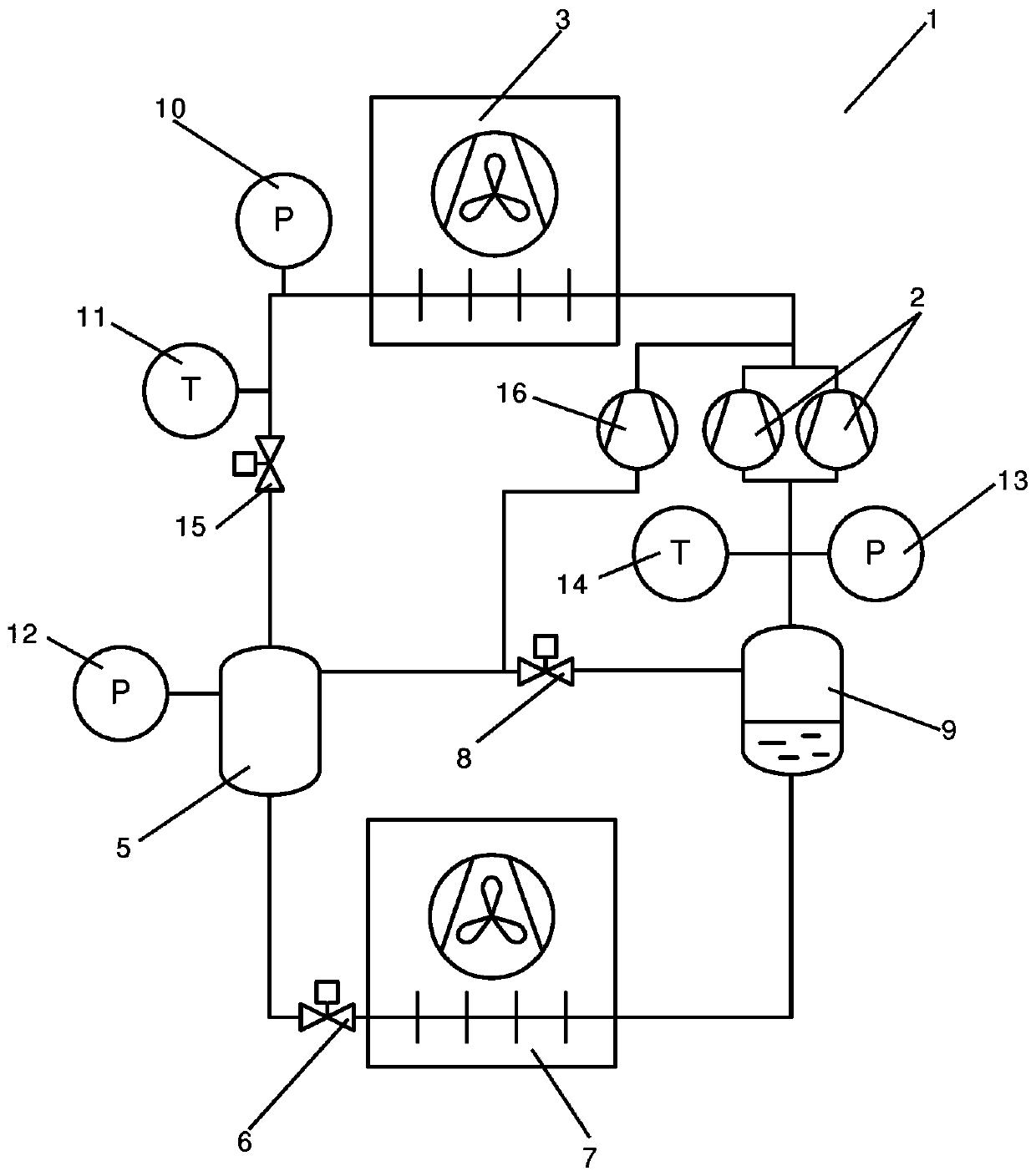

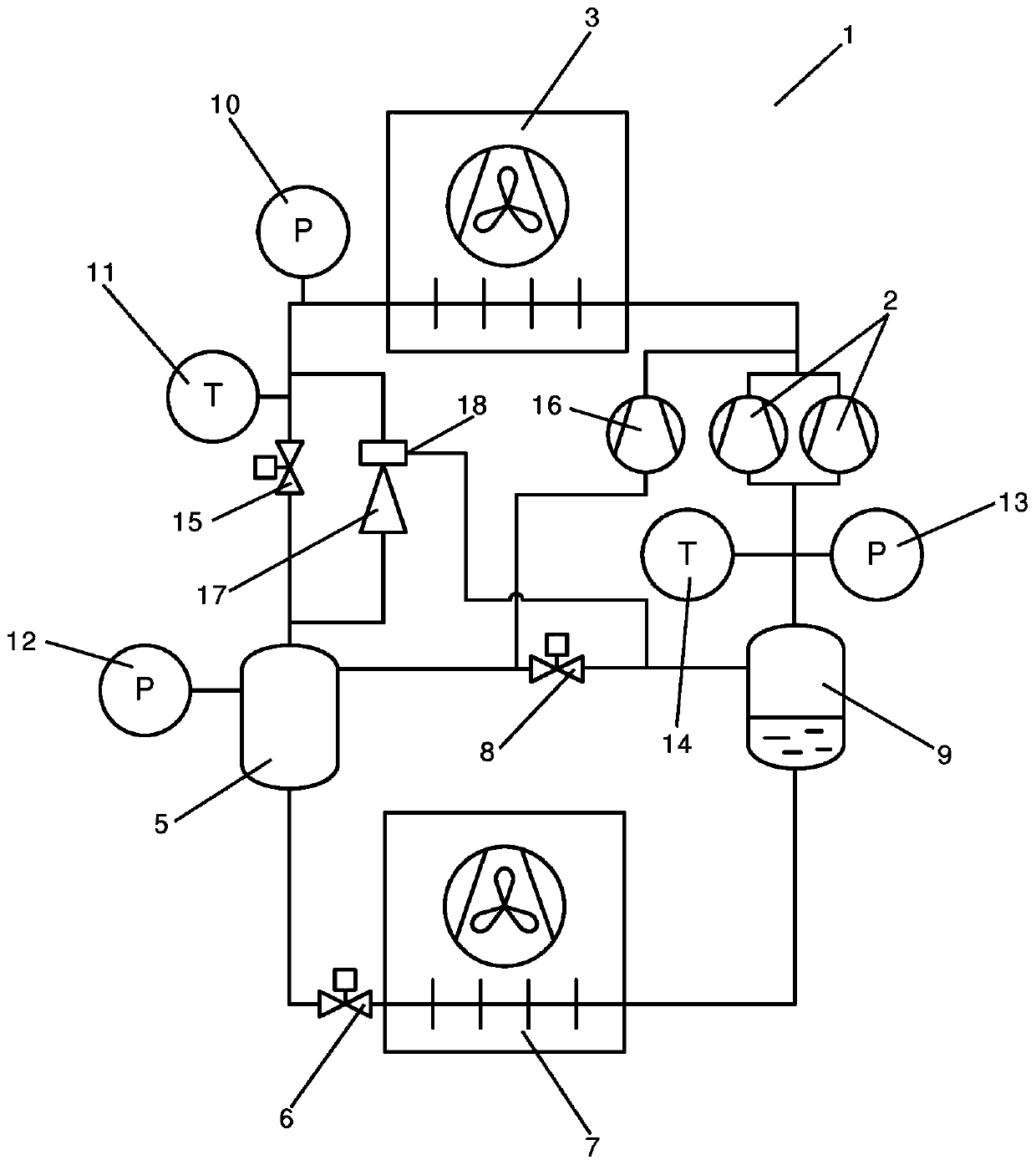

[0048] figure 1 is a simplified diagram of a vapor compression system 1 controlled using a method according to a first embodiment of the invention. A vapor compression system 1 comprises a compressor unit comprising a plurality of compressors 2 (two of which are shown) arranged in a refrigerant path, a heat rejection heat exchanger 3, a high pressure expansion device 4, a receiving 5, an evaporator expansion device 6 in the form of an expansion valve, an evaporator 7, a gas bypass valve 8, and a suction line receiver 9.

[0049] The refrigerant flowing in the refrigerant path is compressed by the compressor 2 before being supplied to the heat rejection heat exchanger 3 . In the heat rejection heat exchanger 3, heat exchange takes place with the auxiliary fluid flow flowing through the heat rejection heat exchanger 3 by removing heat from the refrigerant. In case the heat rejection heat exchanger 3 is in the form of a condenser, the refrigerant passing through the heat reject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com