Drilling design method for steel building materials

A design method and building material technology, applied in metal processing equipment, drilling/drilling equipment, boring/drilling, etc., can solve problems such as lack of legibility, difficulty in rechecking program correctness, inconvenient use, etc. Achieve the effect of easy and rapid design and easy review

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

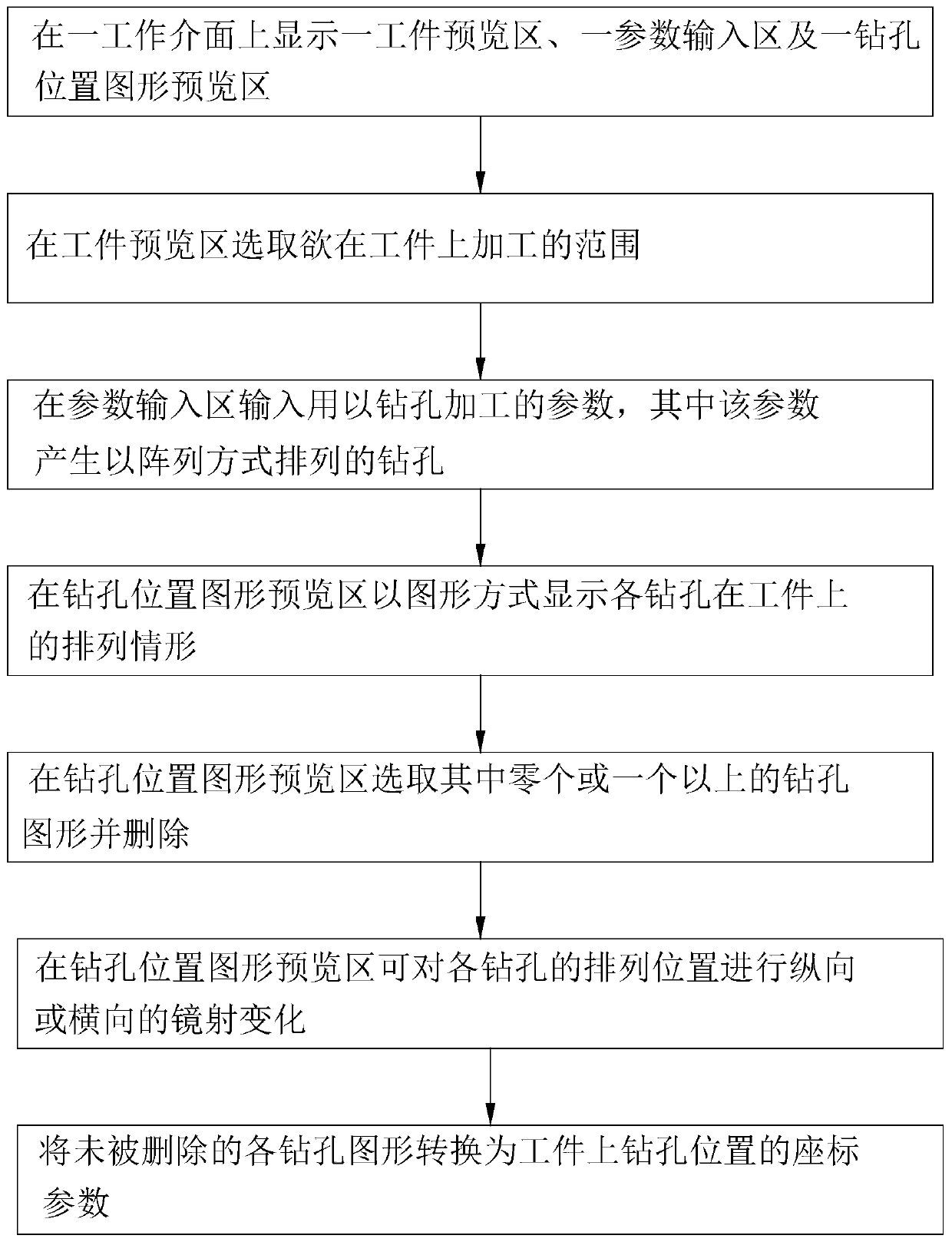

[0019] see figure 1 , the one shown is the drilling design method of the steel building material provided by the present invention, which includes:

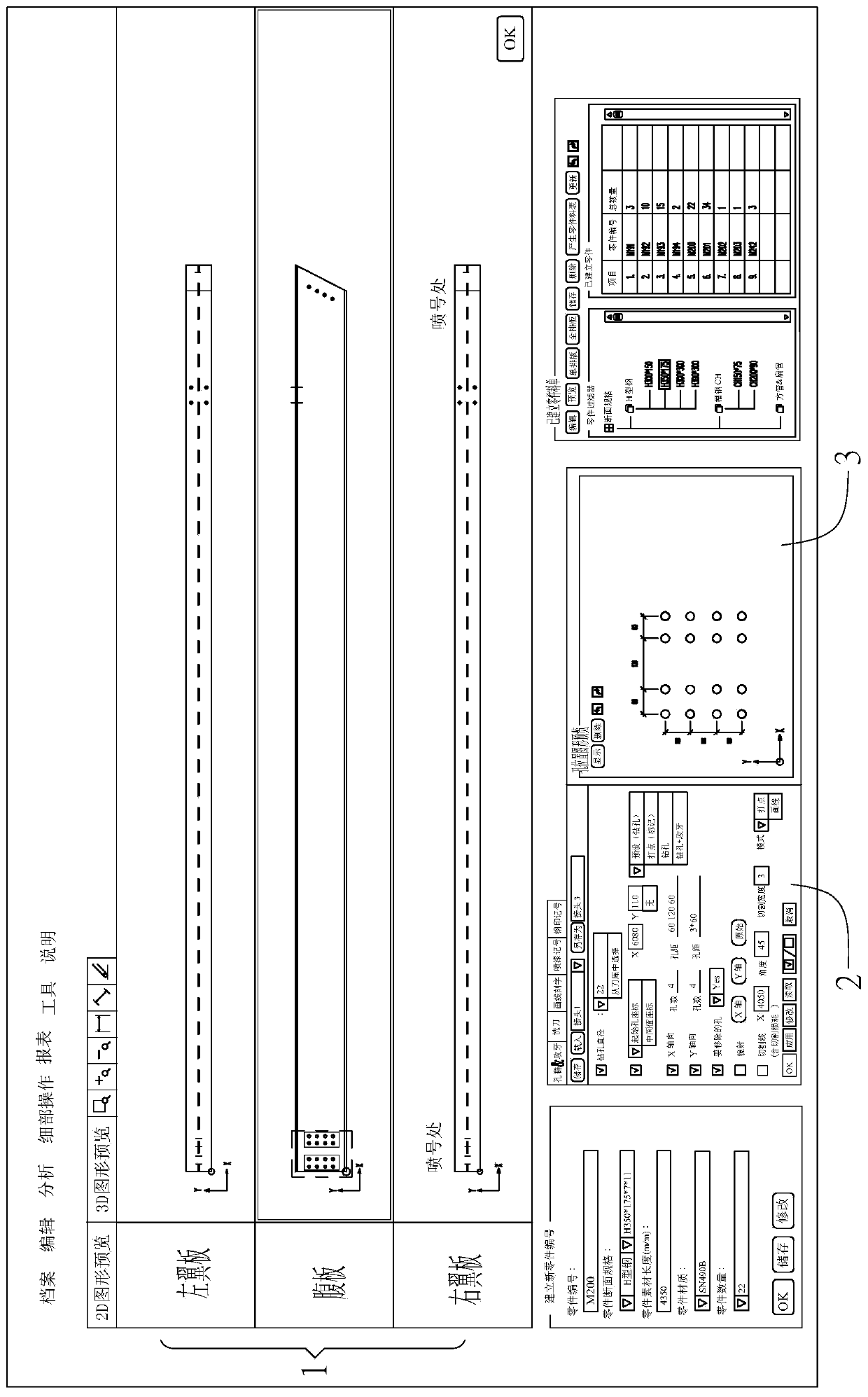

[0020] Displaying a workpiece preview area, a parameter input area and a drilling position graphic preview area on a working interface;

[0021] Select the area to be processed on the workpiece in the workpiece preview area;

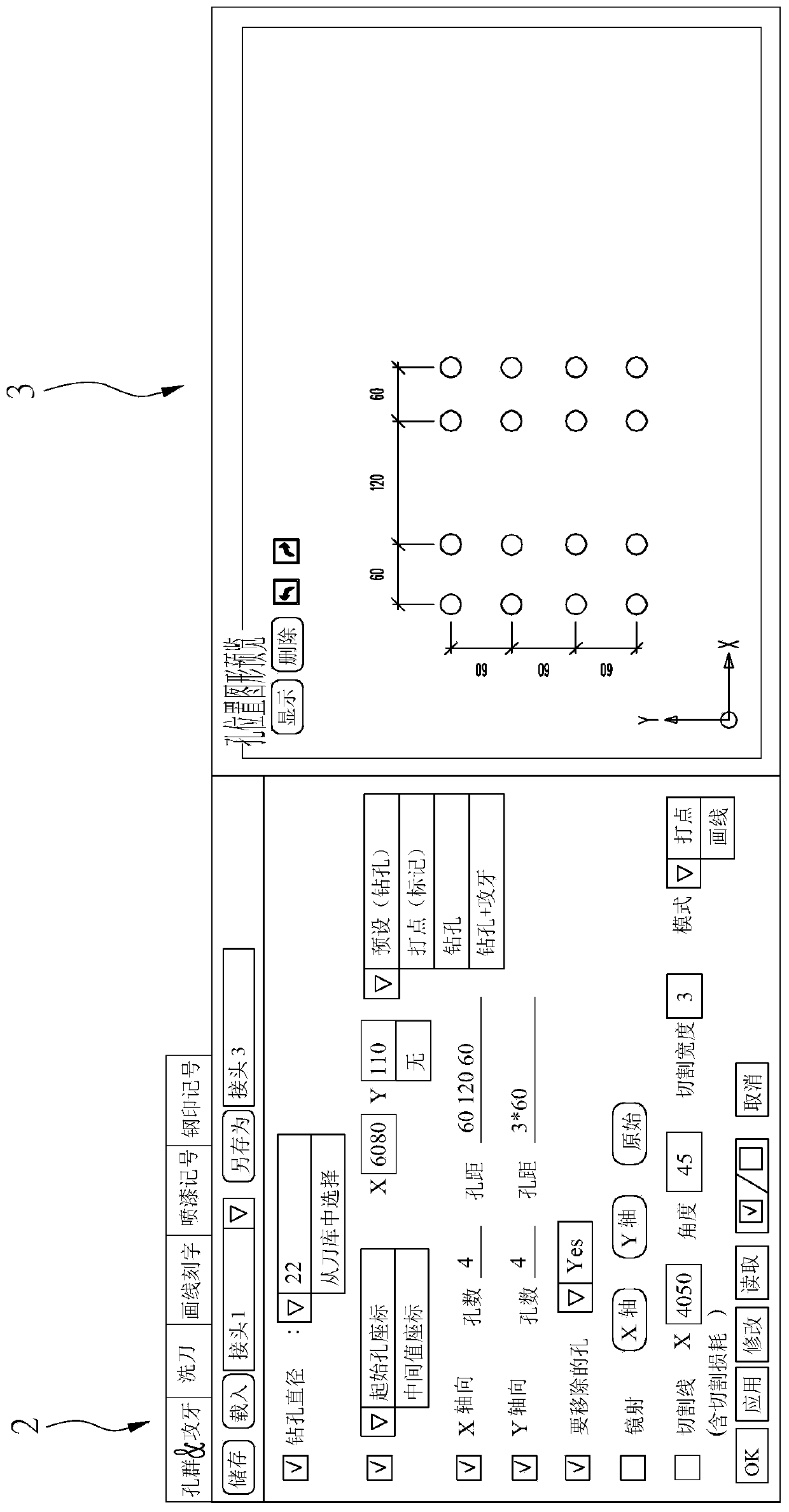

[0022] Input the parameters used for drilling in the parameter input area, wherein the parameters generate drilling holes arranged in an array;

[0023] The arrangement of each drill hole on the workpiece is displayed graphically in the drill hole position graphic preview area;

[0024] Select zero or more than one drilling pattern in the drilling position pattern preview area and delete it;

[0025] In the drill hole position graphics preview area, the arrangement position of each drill hole can be mirrored vertically or horizontally;

[0026] Convert each drilling pattern that has not been deleted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com