Silica gel part forming equipment

A technology for molding equipment and silicone parts, applied in the field of silicone parts molding equipment, can solve the problems of uneven shape of plugging parts, increase of enterprise cost, irregular operation, etc., so as to facilitate later maintenance, increase production rate, and facilitate operation quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

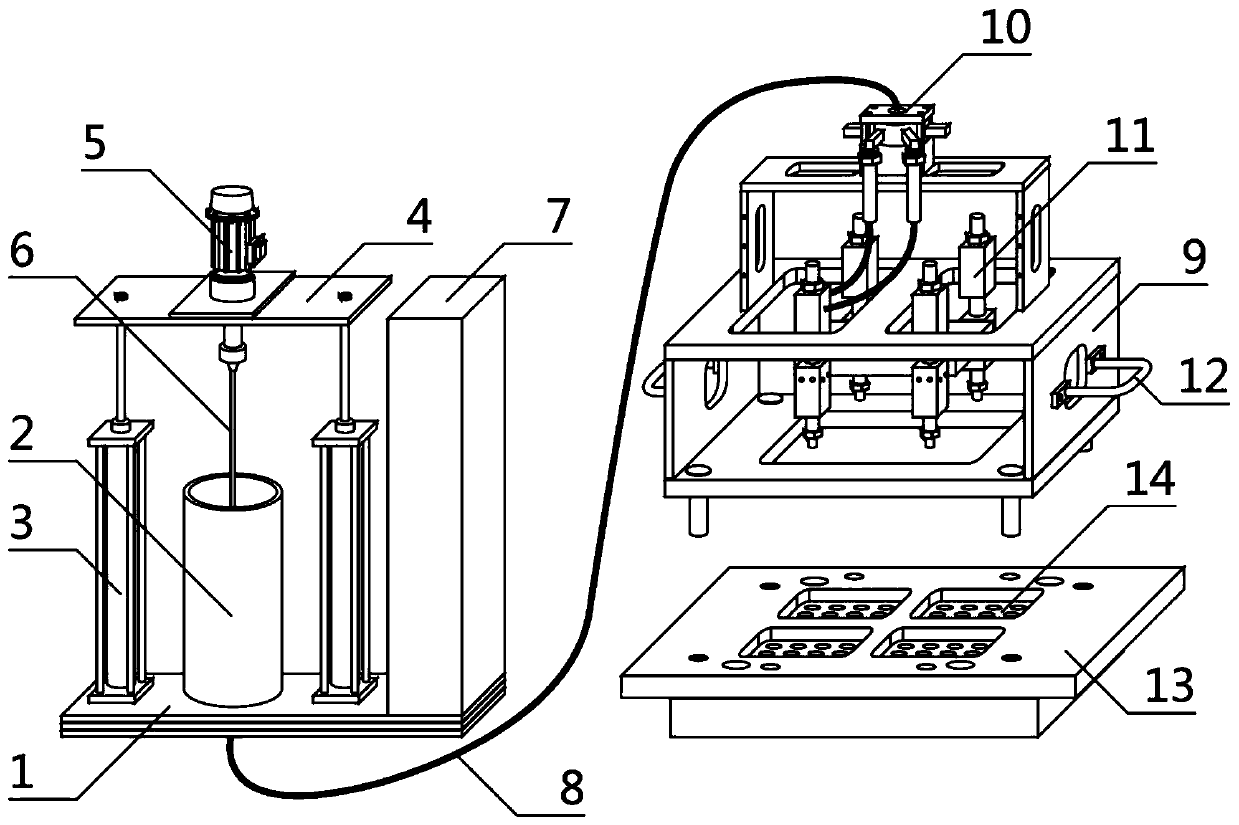

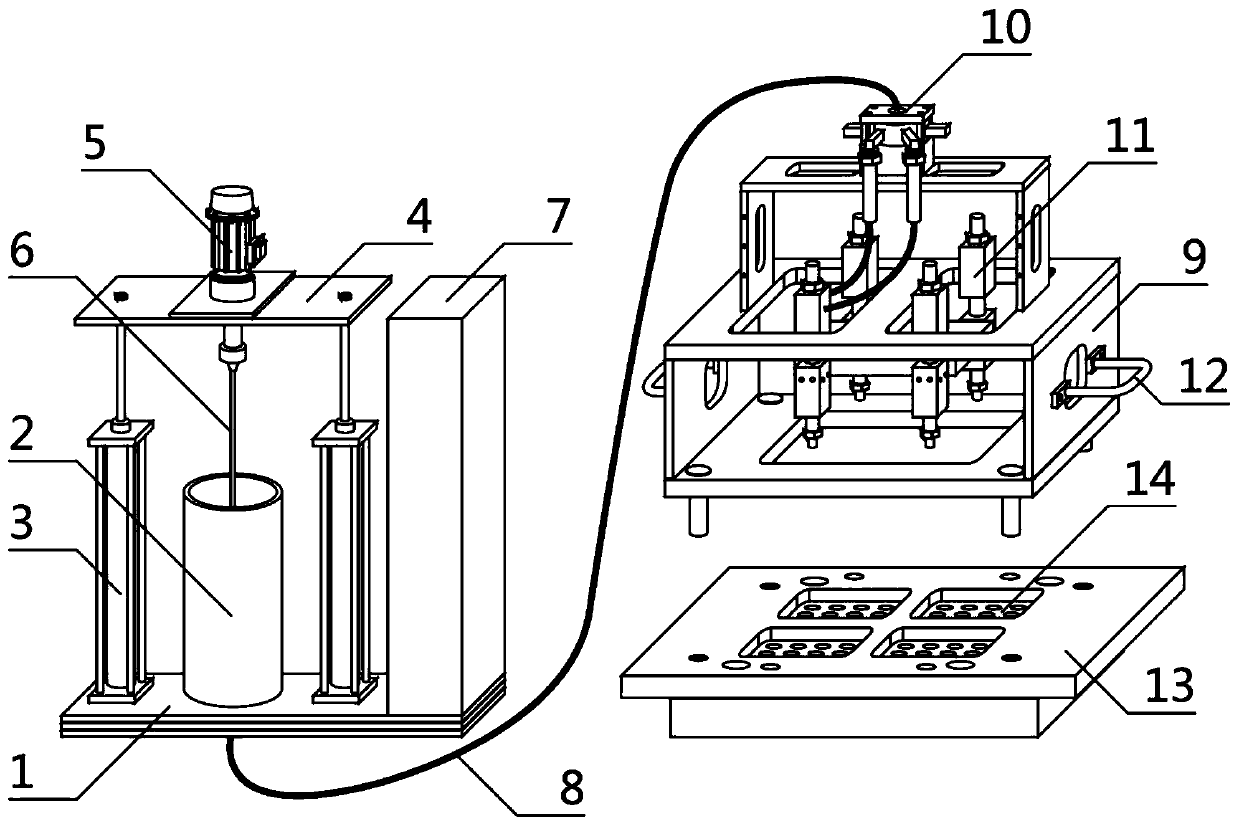

[0020] Such as figure 1 A molding equipment for silicone parts shown is characterized in that it consists of a frame 1, a barrel 2, two lifting devices 3, a lifting platform 4, an electric control box 7, a glue injection frame 9 and a molding template 13. The cylinder 2 is located on the top of the frame 1, the material cylinder 2 is fixedly connected to the frame 1, and the two lifting devices 3 are respectively located on both sides of the material cylinder 2 in parallel, and the two lifting devices 3 are connected to the frame. 1 is a fixed connection, the lifting platform 4 is located on the top of the two lifting devices 3 and the barrel 2, the lifting platform 4 is fixedly connected with the two lifting devices 3, and the lifting platform 4 is also provided with a stirring drive 5 And stirring rod 6, described stirring driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com