A segmented dye pretreatment tube for printing and dyeing

A segmented, pretreatment technology, applied in filtration treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of segmented treatment of fibrous materials that cannot be filamentous and fluffy, affecting advanced treatment, etc. problems, to achieve the effect of improving the interception effect, avoiding shaking off, and avoiding detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

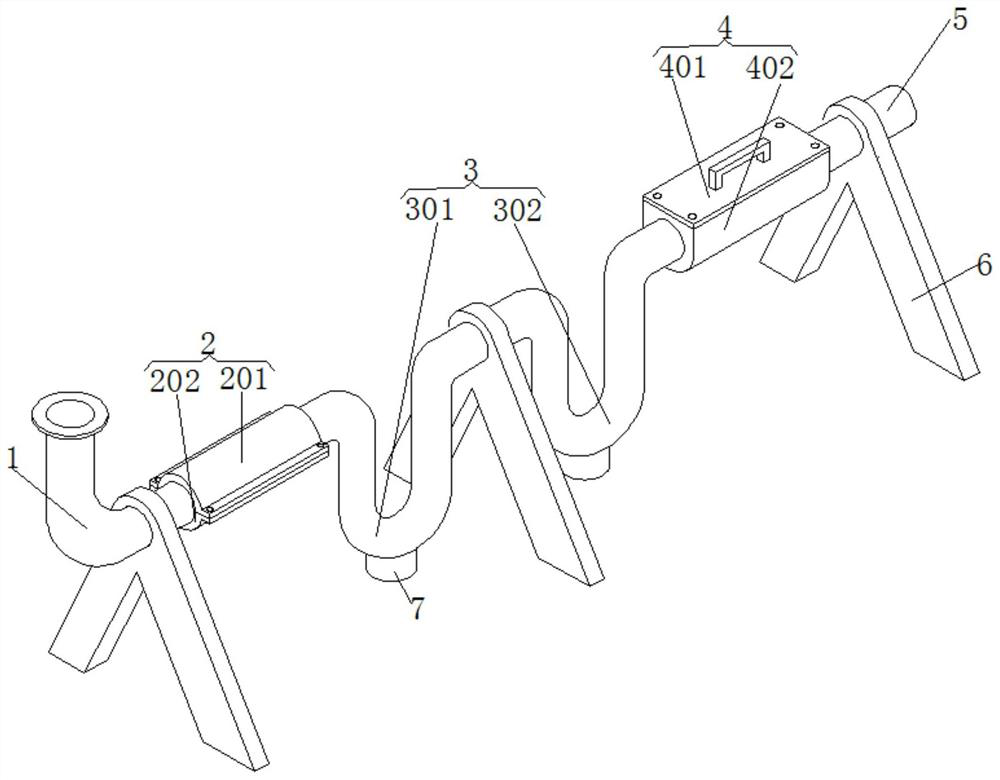

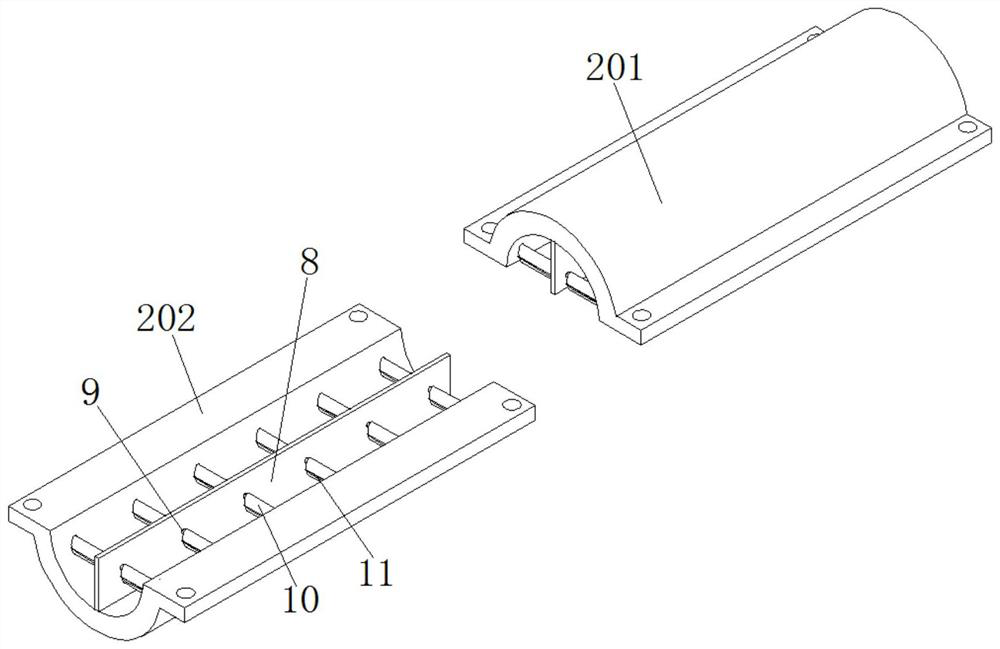

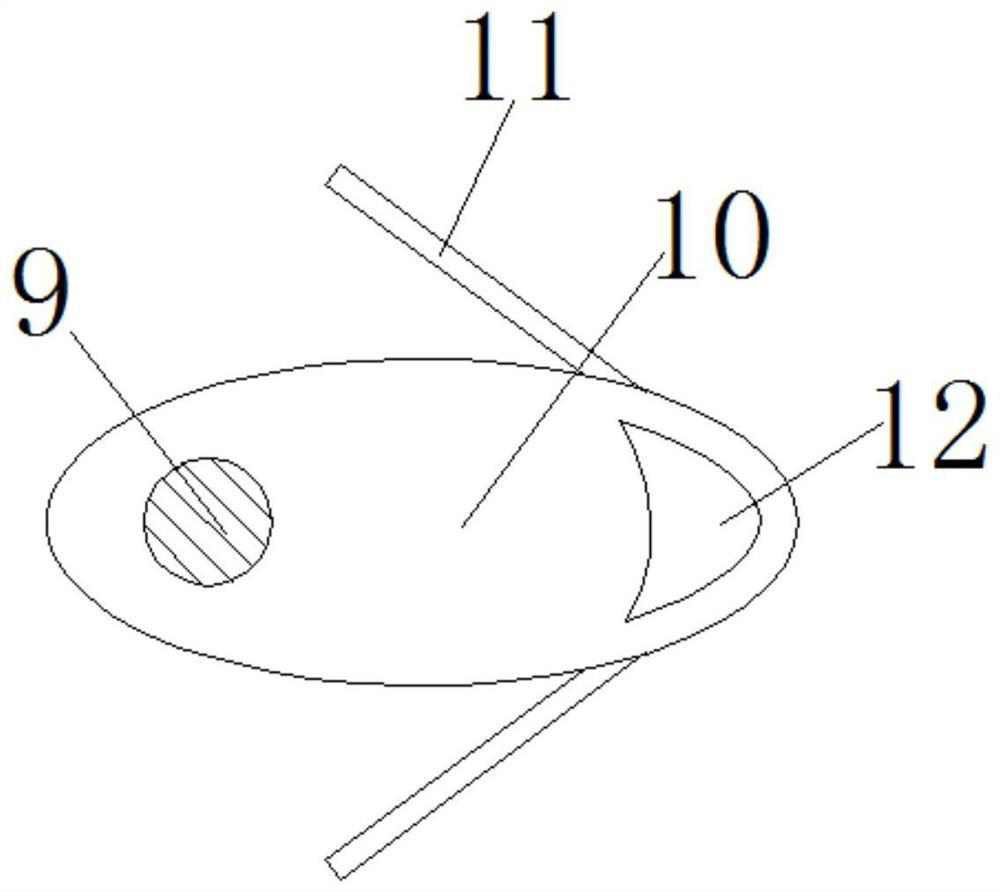

[0024] Embodiment: A dye segmented pretreatment pipe for printing and dyeing, as shown in Figures 1-8, includes a water inlet pipe 1, and one side of the water inlet pipe 1 is equipped with a fiber retaining pipe-2, and a fiber retaining pipe-2 It includes an upper tube shell 201 and a lower tube shell 202, the upper tube shell 201 and the lower tube shell 202 are fixedly connected to one side of the water inlet pipe 1 by bolts, the upper tube shell 201 is located at the top of the lower tube shell 202, and the upper tube A vertical plate 8 is installed at the center of the shell 201 and the lower tube shell 202. A rotating shaft 9 is installed on the vertical plate 8. The two ends of the rotating shaft 9 are respectively fixedly connected with a retaining plate 10. The cross section of the retaining plate 10 is elliptical. Shaped structure, and the end of the intercepting plate 10 away from the rotating shaft 9 is provided with a cavity 12, the surface of the elliptical struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com