A textile disinfection device

A disinfection device and textile technology, applied in the field of textile processing, can solve the problems of affecting the disinfection effect, low efficiency, and affecting the contact between ozone and textiles, so as to improve the disinfection effect, improve fluidity, and improve the disinfection effect of ozone and ultraviolet rays. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

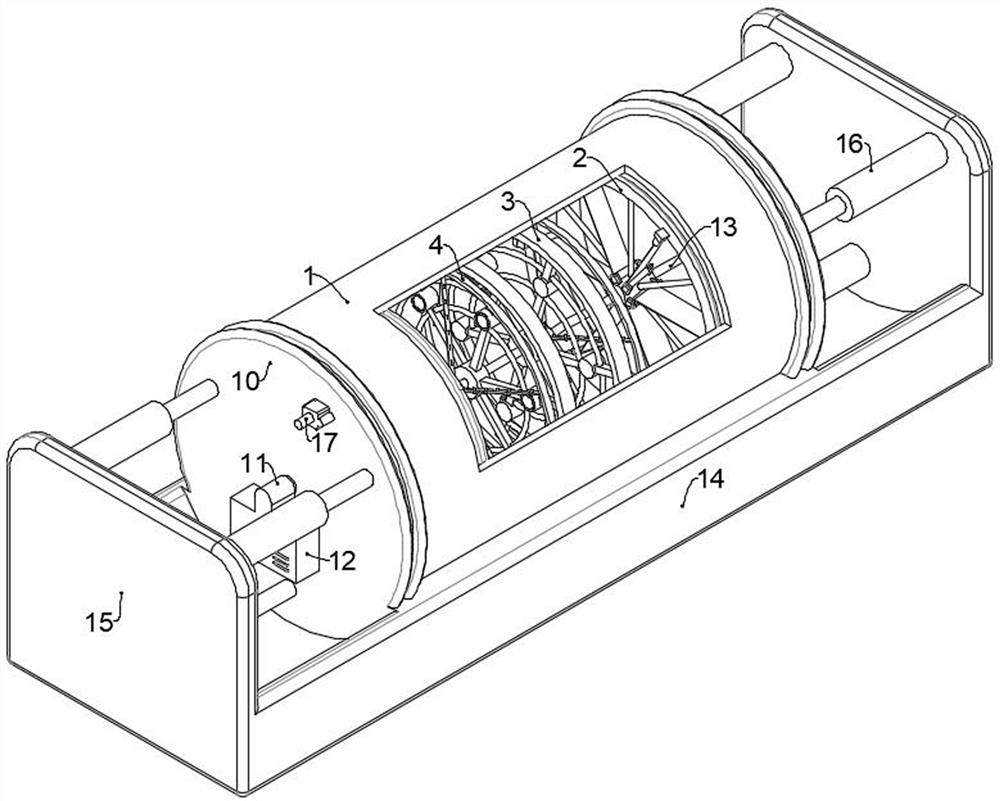

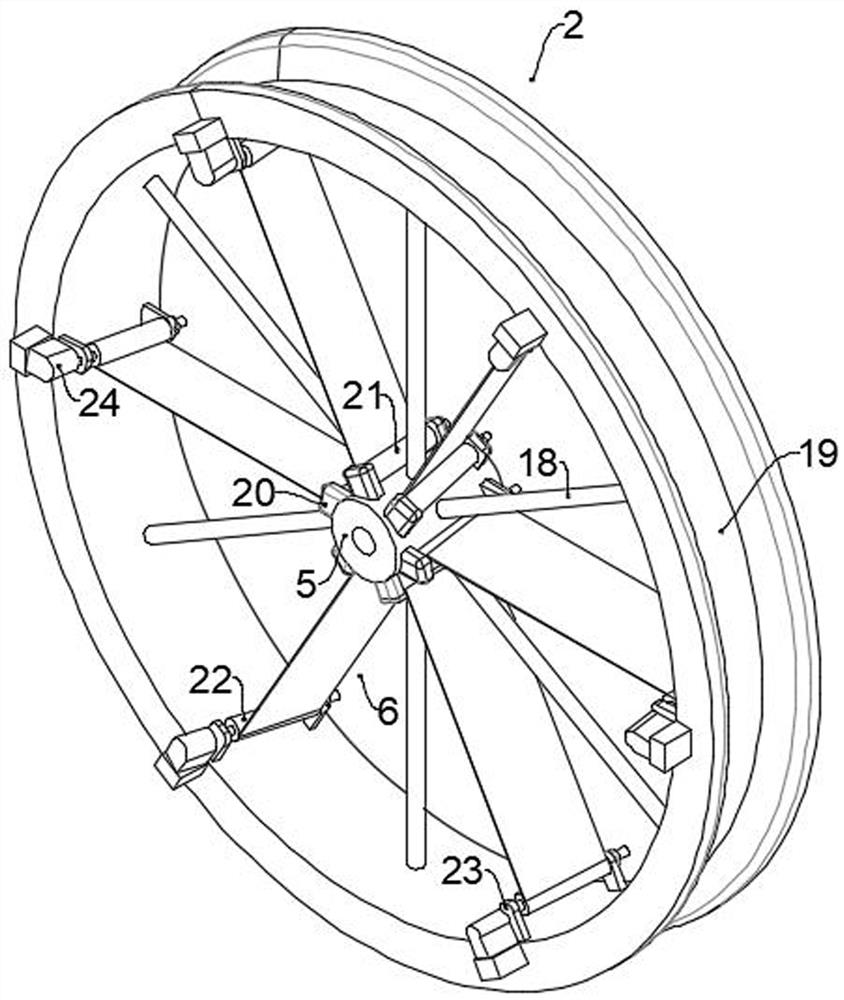

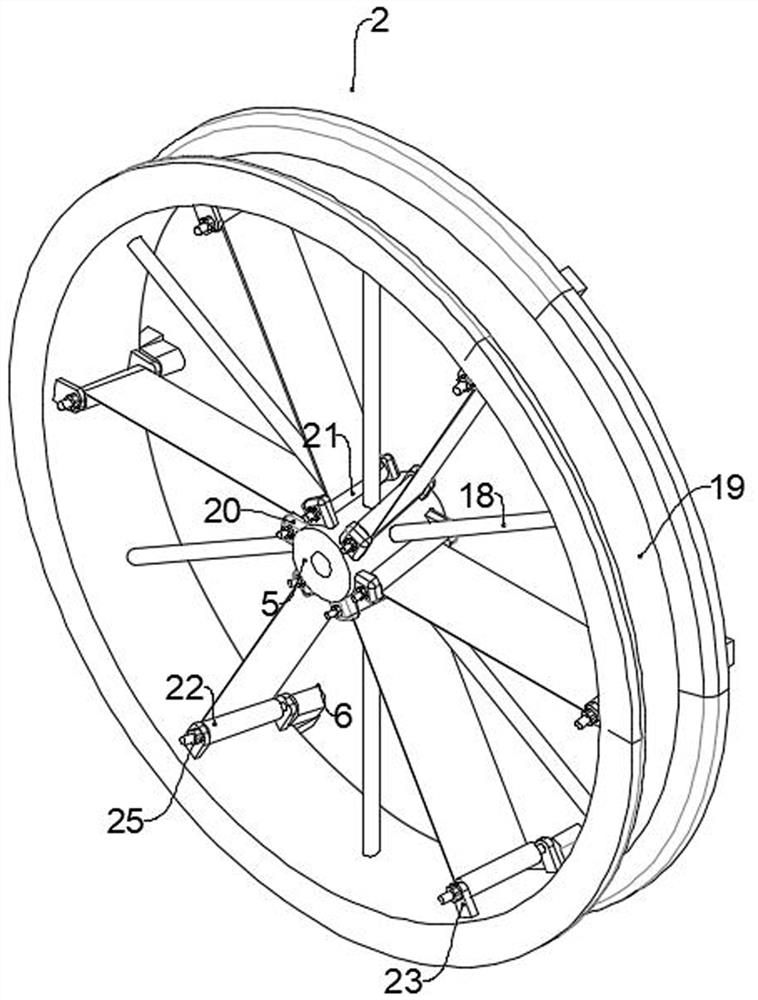

[0028] Such as Figure 1-6 As shown, a textile disinfection device includes a disinfection box 1 and a support mechanism 2 arranged inside the disinfection box 1 for supporting textiles, a disinfection mechanism 3 for ultraviolet disinfection and ozone production, and a refraction mechanism 4 for refracting ultraviolet rays , the quantity of supporting mechanism 2 is two, the quantity of sterilizing mechanism 3 is four, and sterilizing mechanism 3 is arranged on the front and back sides of supporting mechanism 2 in pairs, can all carry out disinfection to the both sides of textiles, refracting mechanism 4 is arranged on the disinfection The mechanism 3 is close to the side of the support mechanism 2. The support mechanism 2 includes a first center block 5 and a roller cloth assembly 6 arranged on the ring side of the first center block 5 for transporting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com