Cushion package and assembling method

A technology of cushioning packaging and cushioning parts, applied in the field of packaging, can solve problems such as high damage rate, poor environmental protection properties, anti-turbulence and compressive strength, etc., and achieve the effect of stable and reliable structure, good protection, beautiful appearance and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention are described with reference to the above drawings.

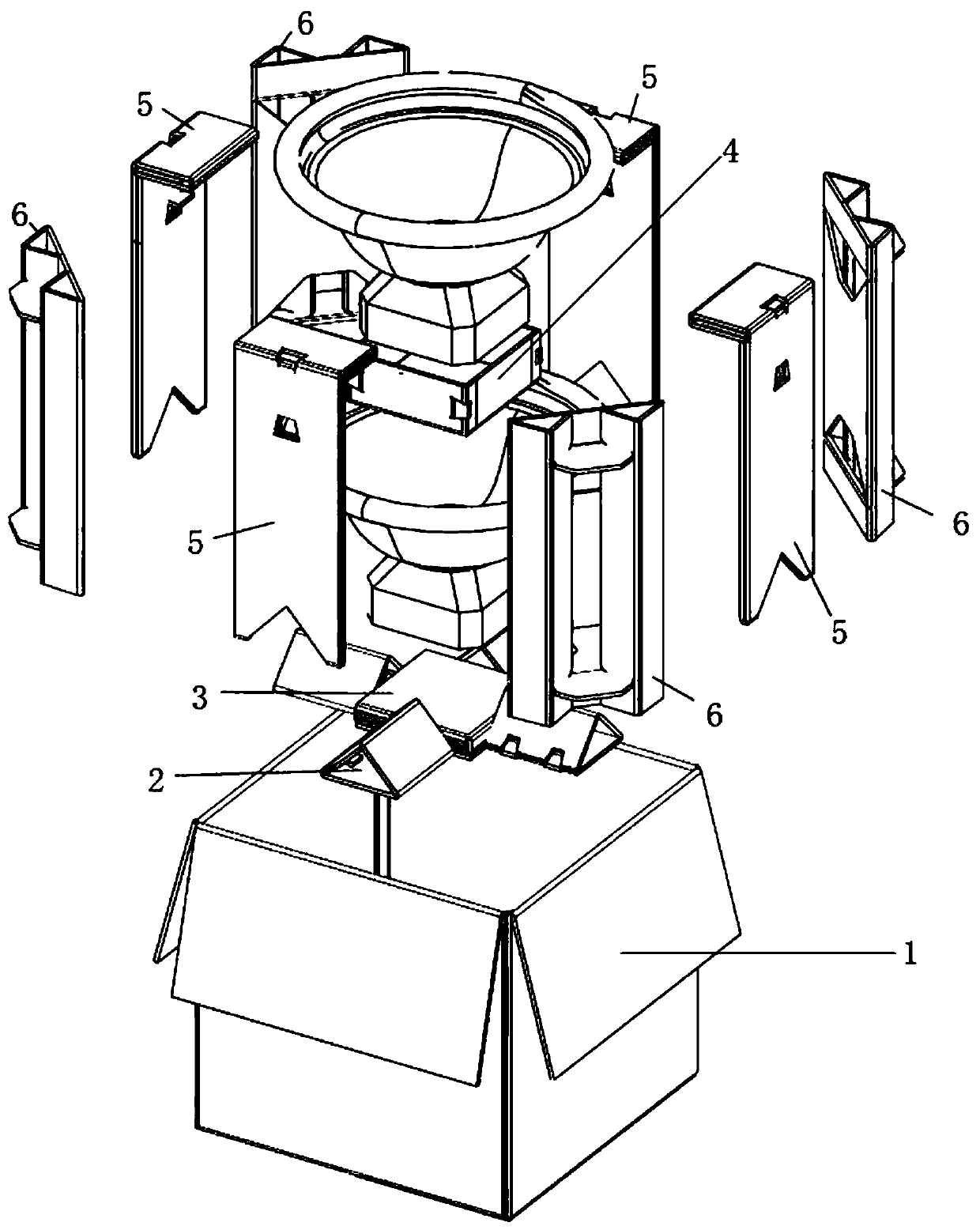

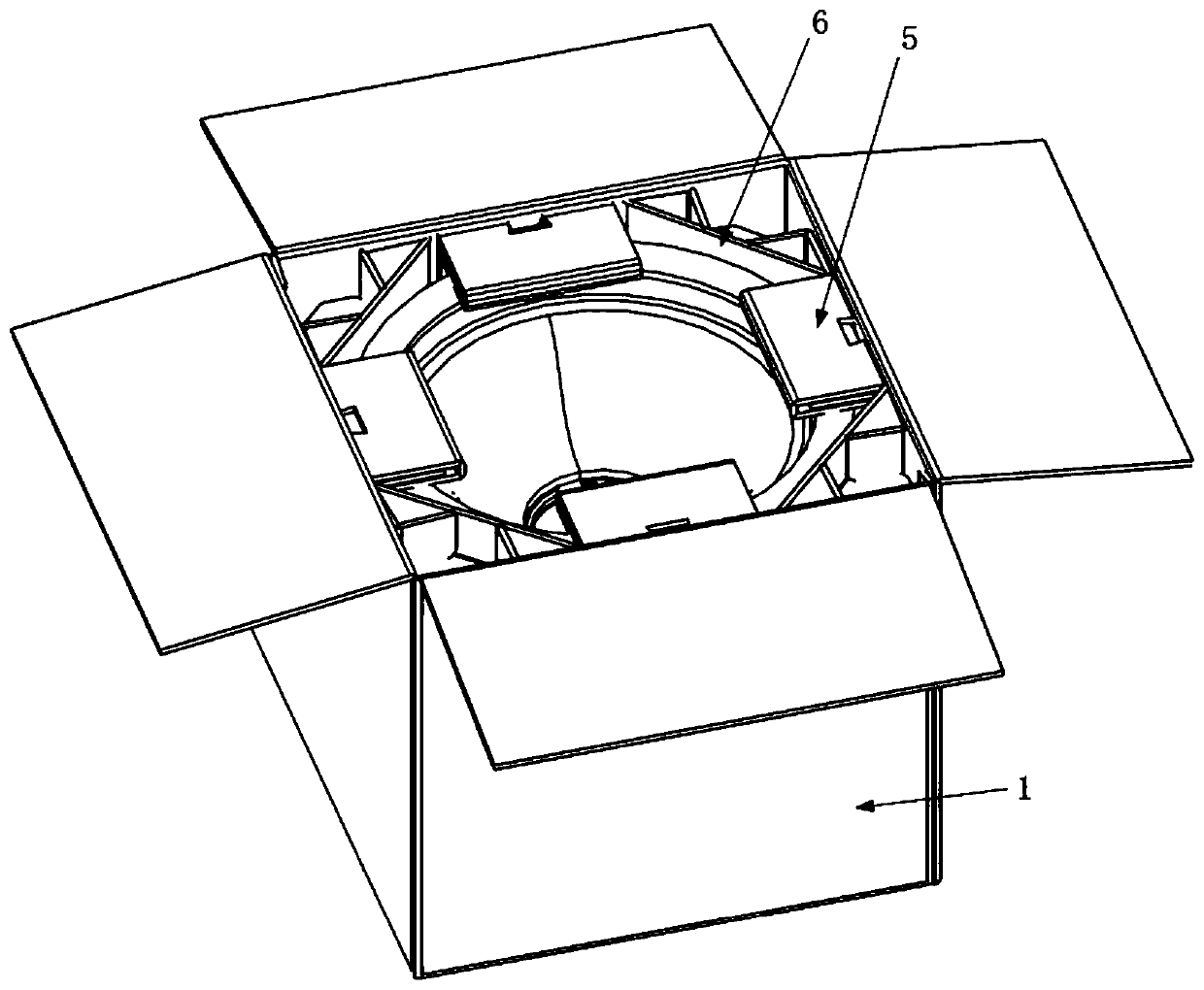

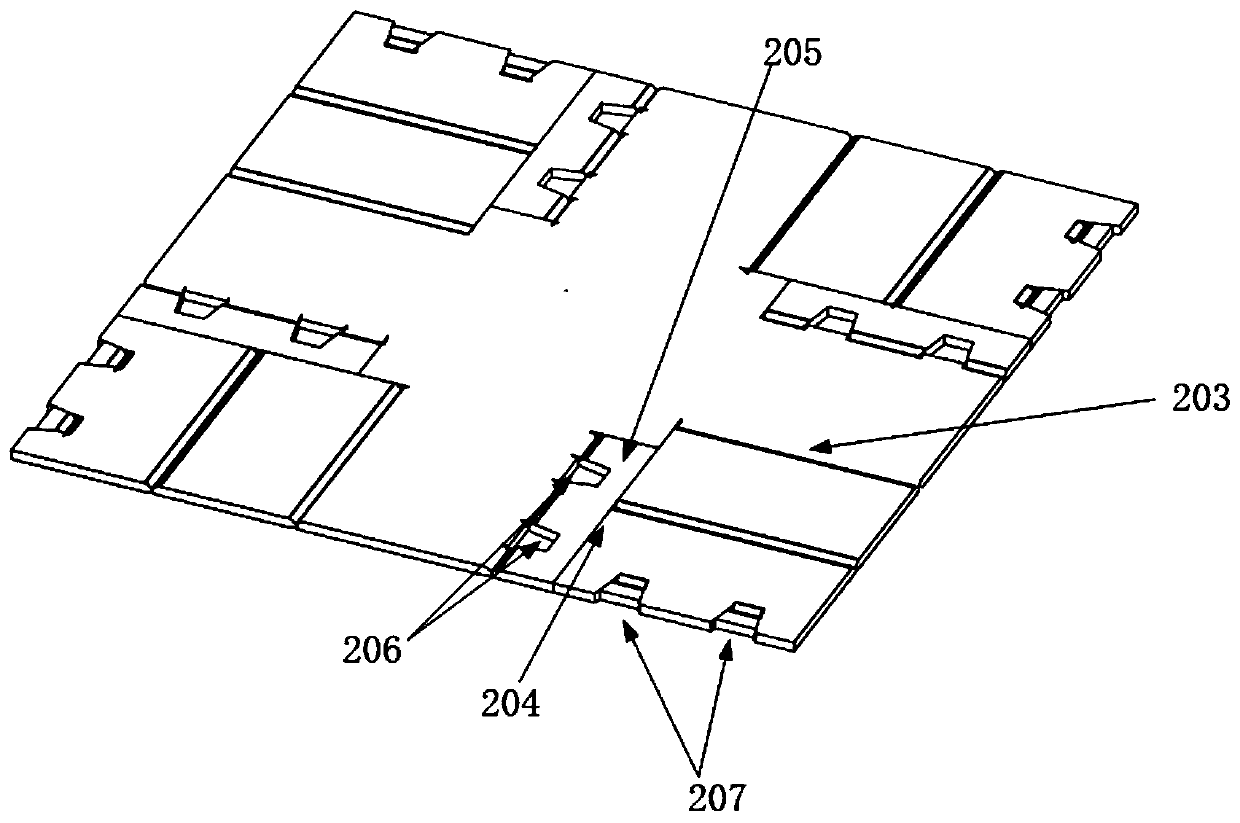

[0028] like figure 1 and figure 2 As shown, the present invention provides a cushioning package, including an outer box 1, a bottom fixing part 2, a bottom buffering part 3, a partition 4, an insert card 5, and a corner protector 6, and the bottom fixing part 2 is arranged on the outer At the bottom of the box 1, the bottom buffer 3 is arranged on the upper surface of the middle part of the bottom fixing part 2, and the card 5 is arranged on the inside of the four walls of the outer box 1, and the opening at the bottom of the card 5 is connected to the bottom. The fixing part 2 is engaged, the corner protectors 6 are arranged at the four corners inside the outer box 1, and the bottom fixing part 2, the insert card 5, and the corner protectors 6 are spliced into a hollow frame , the outer walls of the bottom fixing part 2, the plug-in card 5, and the corner protector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com