Special-shaped steel pipe, iron-making blast furnace cooling wall, butt-fitting tool and butt-fitting method of special-shaped steel pipe

A technology for special-shaped steel pipes and iron-making blast furnaces, which is applied in the direction of cooling devices, etc., can solve problems such as lack of matching methods, out-of-tolerance diagonals, rework, etc., to solve the problems of matching quality and efficiency, improve work efficiency, and be economical benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

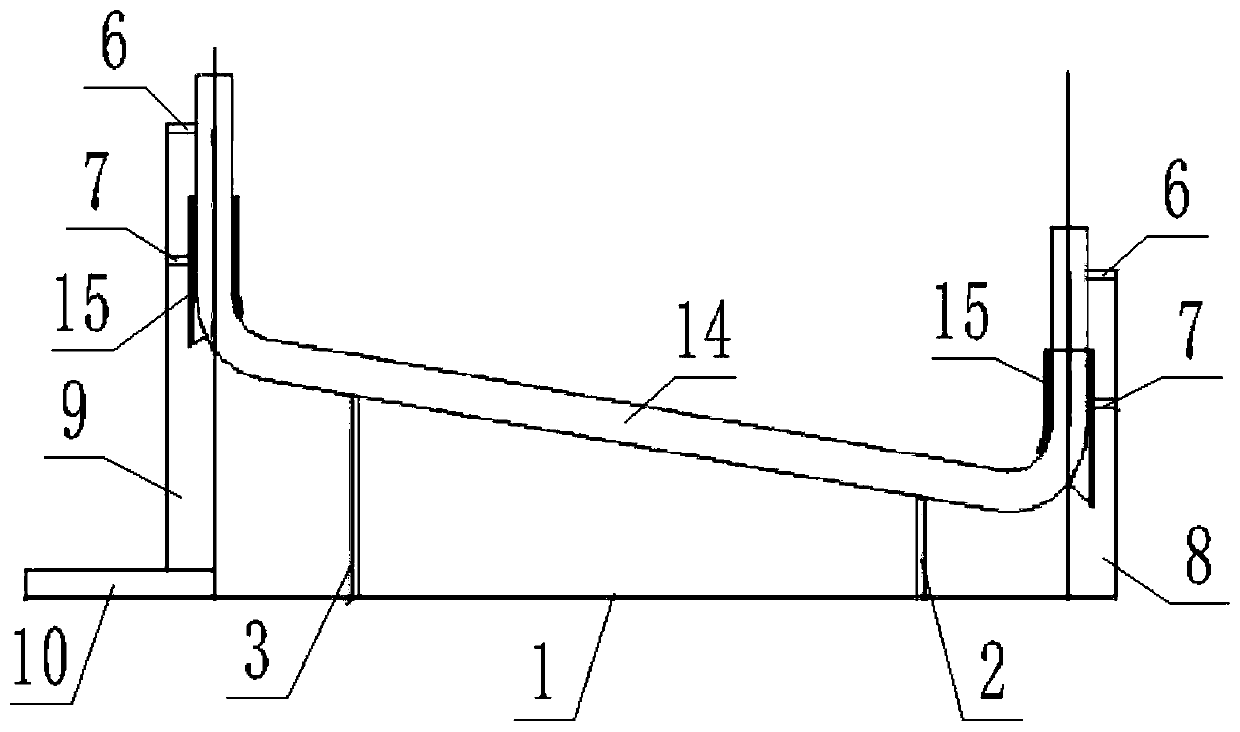

[0036] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0037] For the convenience of description, according to the shape of the special-shaped steel pipe in the cooling wall, the high end of the special-shaped steel pipe is defined as the head end, and the low end is defined as the tail end.

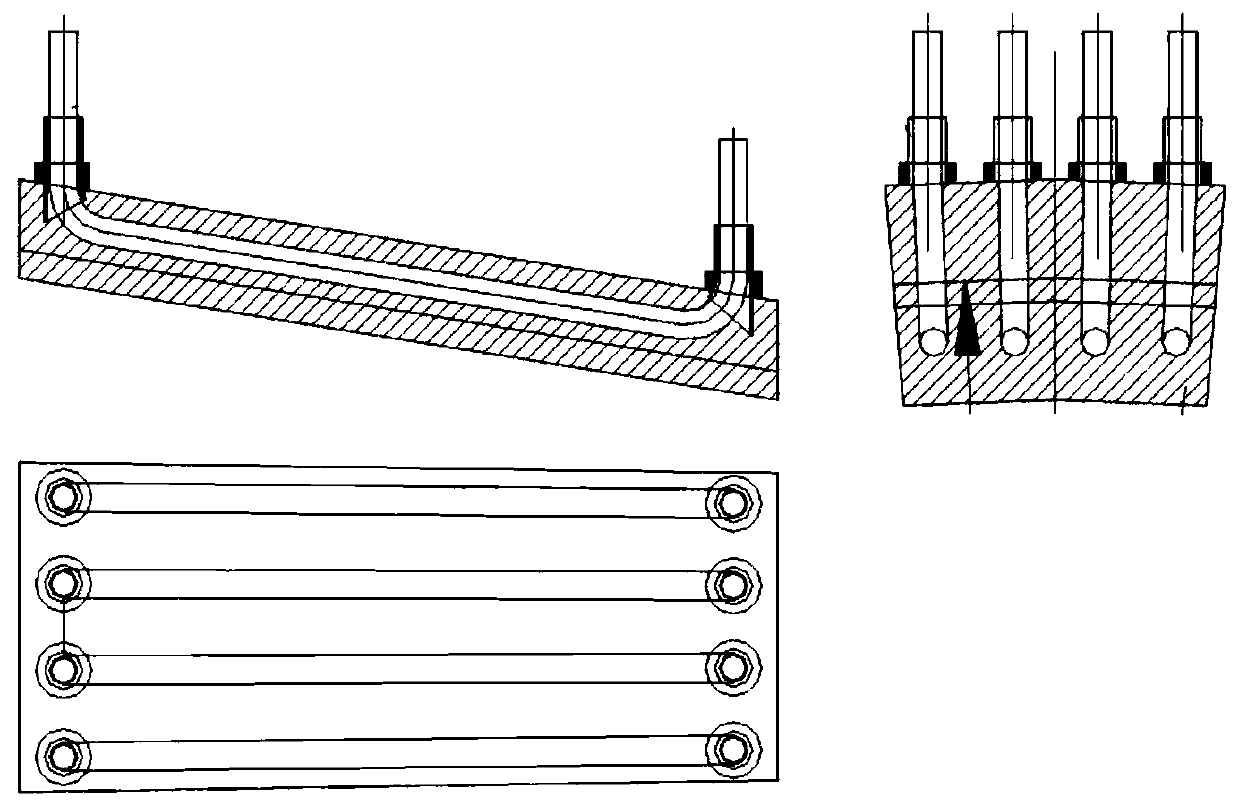

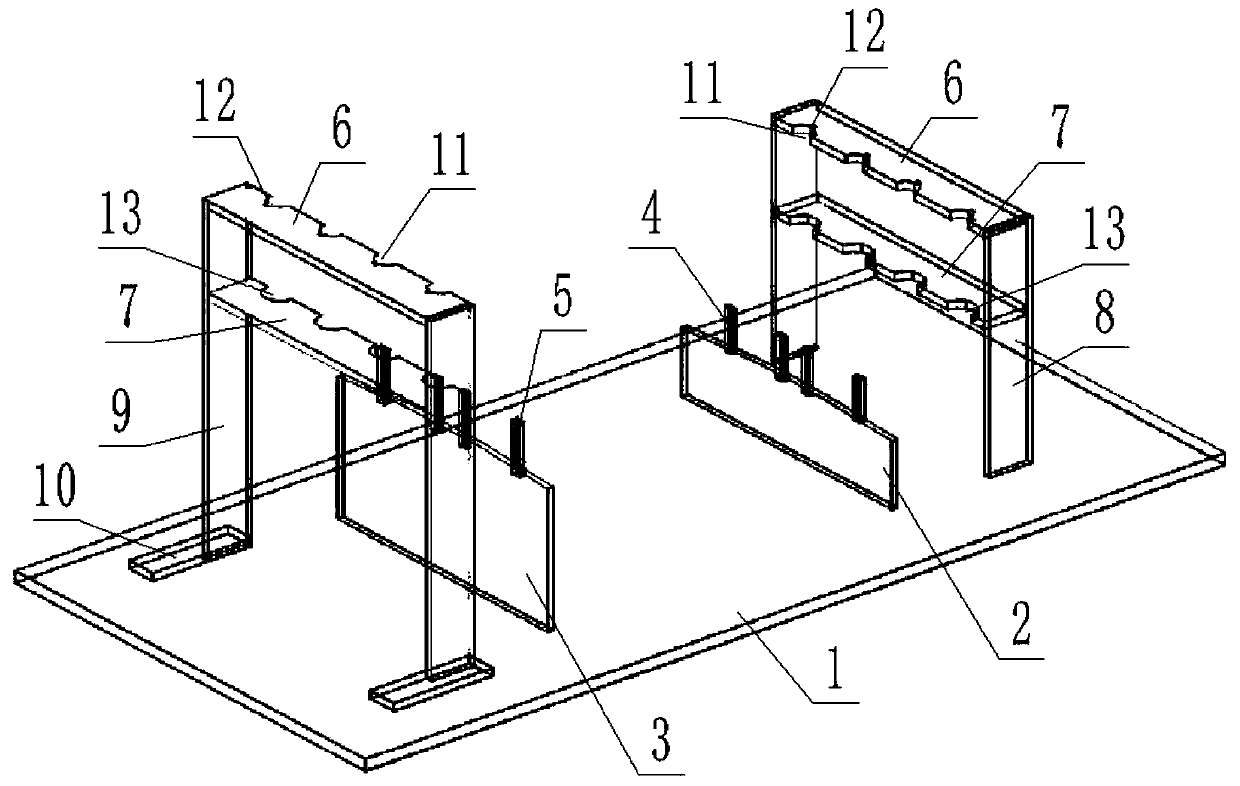

[0038] An iron-making blast furnace cooling wall special-shaped steel pipe matching tool, such as figure 2 , 3 , shown in 4, including the base plate 1, the two ends on the upper surface of the base plate 1 are respectively provided with a head-end pairing device for mounting a plurality of special-shaped steel pipes 14 heads and a tail-end pair for mounting a plurality of special-shaped steel pipes 14 tail ends The mounting device is fixedly connected to the base plate 1, the head mounting device is movably connected to the base plate 1, and the head mounting device can be manually mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com