Solid engine charging low-temperature stress equivalent acceleration test method

A solid engine and accelerated test technology, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of not meeting the special requirements for model storage and long test periods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The low temperature stress equivalent accelerated test of a NEPE propellant Φ200mm circular tube engine charge (hereinafter referred to as "Type I NEPE charge"), the specific steps are as follows:

[0048] (1) 600 dumbbell-shaped samples of a certain NEPE propellant and 3 rounds of Type I NEPE charges were prepared, wherein the length of Type I NEPE charges was 700mm, the depth of both ends was 20mm, the inner diameter was 20mm, and the outer diameter was 200mm , The shell thickness is 5mm.

[0049] (2) Under the conditions of temperature 20°C±5°C and humidity ≤55%RH., the constant strain fracture test was carried out using NEPE propellant standard dumbbell samples, and the constant strain levels were: 80%, 75%, 70%, 65% %, 60%, and 5 samples under each strain level, the relaxation fracture time of the high strain region of the sample is obtained, see Table 2.

[0050] (3) Use a standard dumbbell-shaped sample of a NEPE propellant, with an aging temperature of 60°C, 3 ...

Embodiment 2

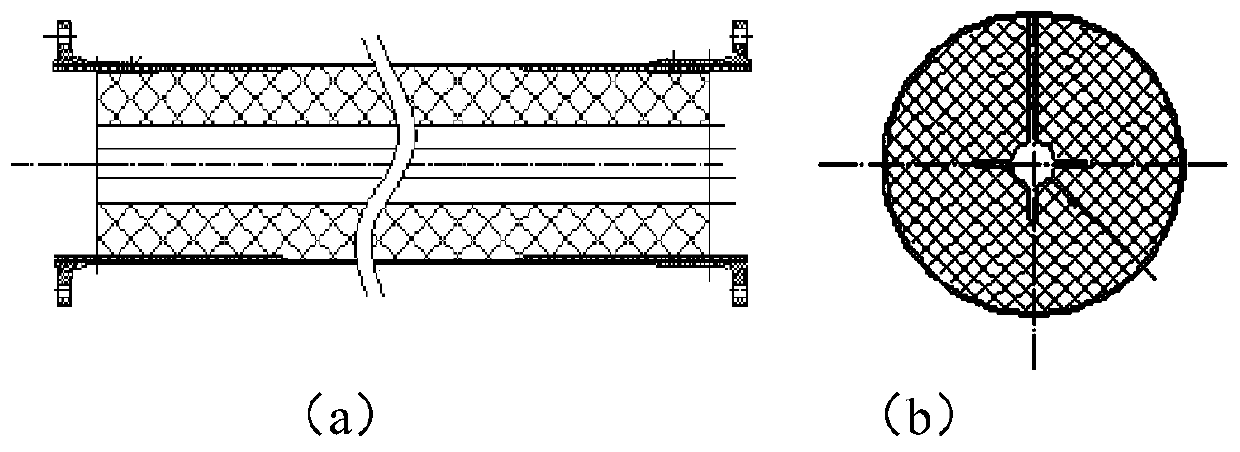

[0075] The low temperature stress equivalent accelerated test of a NEPE propellant Φ200*1100mm star hole type engine charge (hereinafter referred to as "Type II NEPE charge"), the specific steps are as follows:

[0076] (1) Prepared 3 rounds of Type II NEPE charges, the charges are star-shaped, with an inner diameter of 30mm and a length of 1100mm. The structure is as follows image 3 shown.

[0077] (2) Since the NEPE propellant formula adopted by type I NEPE charge and II type NEPE charge is the same, so the NEPE propellant relaxation and fracture time model in this example is the same as that in Example 1, see in Example 1 Formula (11).

[0078] (3) One round of Type II NEPE charge was used to conduct a progressive cooling test. When the charge reached temperature equilibrium at each temperature, its structural integrity was judged by CT flaw detection, and then the ultimate failure temperature of the charge was determined. The test results See Table 5. The test results ...

Embodiment 3

[0086] The low temperature stress equivalent accelerated test of a HTPB propellant Φ200mm circular tube motor charge (hereinafter referred to as "HTPB charge"), the specific steps are as follows:

[0087] (1) 600 dumbbell-shaped samples of a HTPB propellant and 3 rounds of HTPB charges were prepared, wherein the length of the HTPB charges was 600mm, the depth of both ends was 20mm, the inner diameter was 20mm, the outer diameter was 200mm, and the shell thickness is 5mm.

[0088] (2) Under the conditions of temperature 20°C±5°C and humidity ≤55%RH., the constant strain fracture test was carried out using the HTPB propellant standard dumbbell-shaped sample, and the constant strain levels were: 15%, 20%, 25% and 30% %, 5 samples under each strain level, the relaxation fracture time of the high strain region of the sample is obtained, see Table 6.

[0089] (3) Use a standard dumbbell-shaped sample of HTPB propellant, aging temperature 50°C, 3 constant strain levels: 5%, 10%, 15%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com