Milking device

A kind of equipment and milk technology, which is applied to milking devices, milk containers, dairy products, etc., can solve the problems of high manual labor and low milking efficiency, and achieve the effect of reducing workload and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

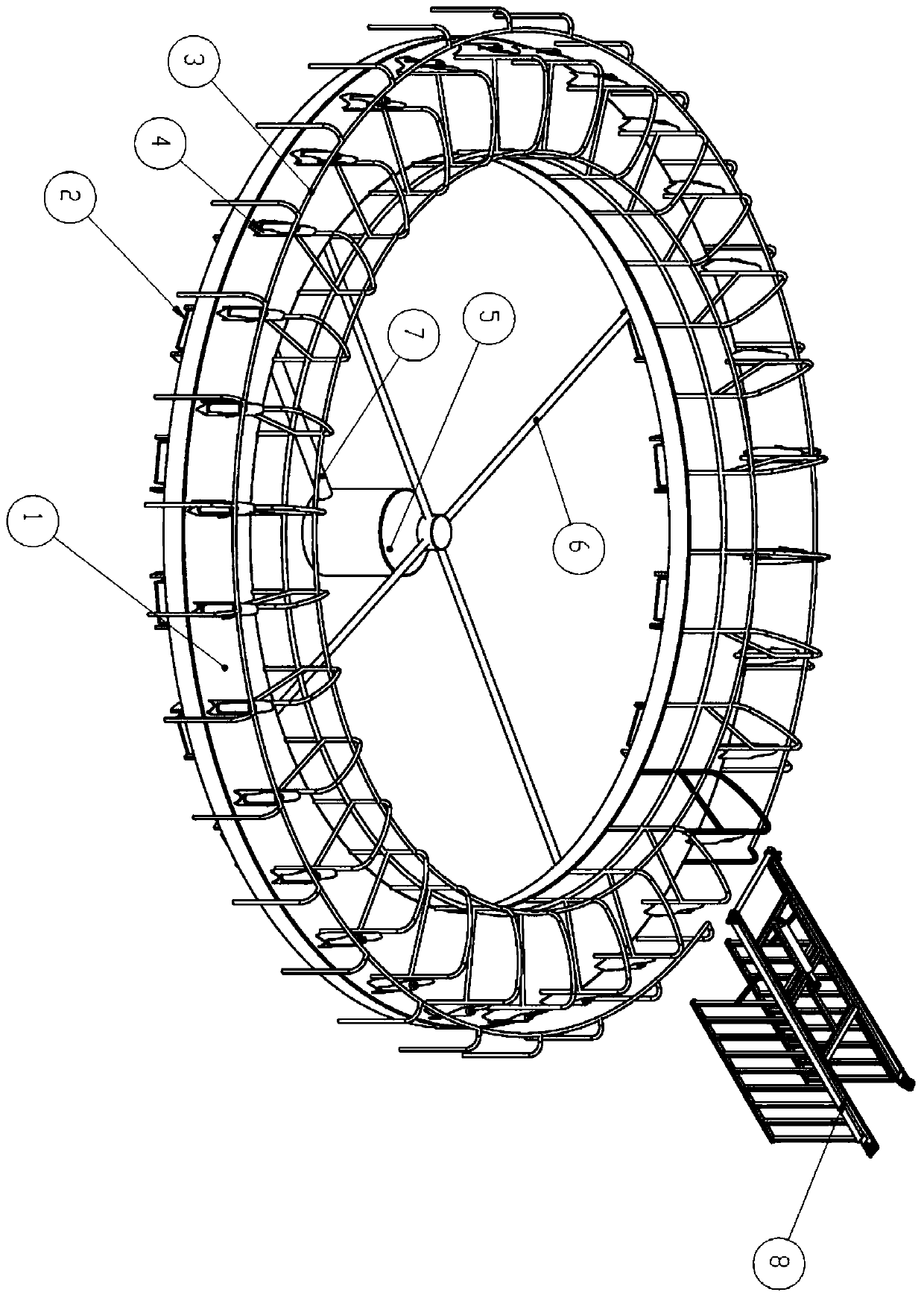

[0026] Such as figure 1 As shown, the present invention provides a milking device, which is suitable for overall milking management of a dairy herd.

[0027] Specifically, the milking equipment includes a turntable track, a cow propeller 8 and a milk collector 5, and the turntable track includes a plurality of track rollers 9, a box track 2 and a turntable 1, and the circular track rollers 9 evenly distributed are installed through shafts. On the support placed on the ground, the axes of multiple track rollers 9 are compared with the center of the circle where the surface of the turntable 1 is, and the turntable 1 rotates along the direction of rotation of the track rollers 9; the disc-shaped box track 2 is placed on the track roller 9 The top is slidably connected with the track roller 9, and the turntable 1 is fixedly installed on the top of the box track 2; the turntable 1 is evenly divided into several milking stations, and each milking station is provided with a milking m...

Embodiment 2

[0032] Such as Figure 1-2 As shown, this embodiment provides a milking device. On the basis of Embodiment 1, the milking device of this embodiment also has the following characteristics:

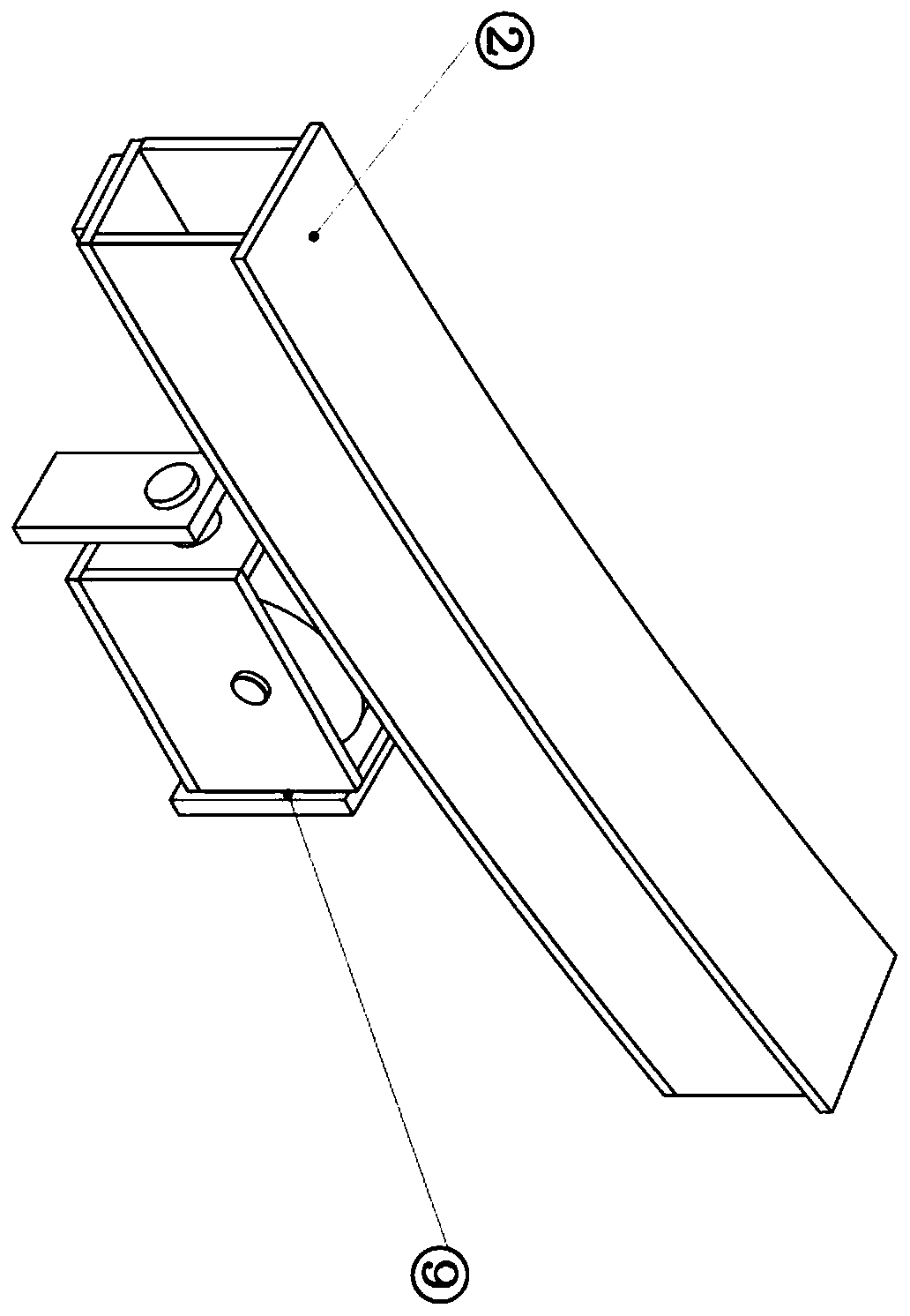

[0033] The track roller 9 is installed in the fixed box through the shaft, and the two ends of the fixed box are fixedly connected with the support through the connecting shaft.

[0034] The box track 2 is a hollow track with a rectangular cross-section. The bottom of the box track 2 is welded symmetrically with grooves. The grooves are connected with the track rollers 9. The top surface of the box track 2 is a plane extending outward on both sides. , The turntable 1 is fixedly installed on the top surface of the box track 2. Both sides of the bottom groove of the box body track 2 are provided with baffle plates fixed on the ground, and the baffle plates are arranged on the circumferential line between two adjacent track rollers 9 at intervals. The setting of the baffle can ensure that th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap