Power battery heat-preservation control method and system for electric vehicle, and vehicle

A power battery and electric vehicle technology, applied in the automotive field, can solve the problems that the heating and holding time does not meet the actual needs, affects the performance of the battery, and cannot be guaranteed, so as to improve the service life and cruising range, solve the limited power, and guarantee performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

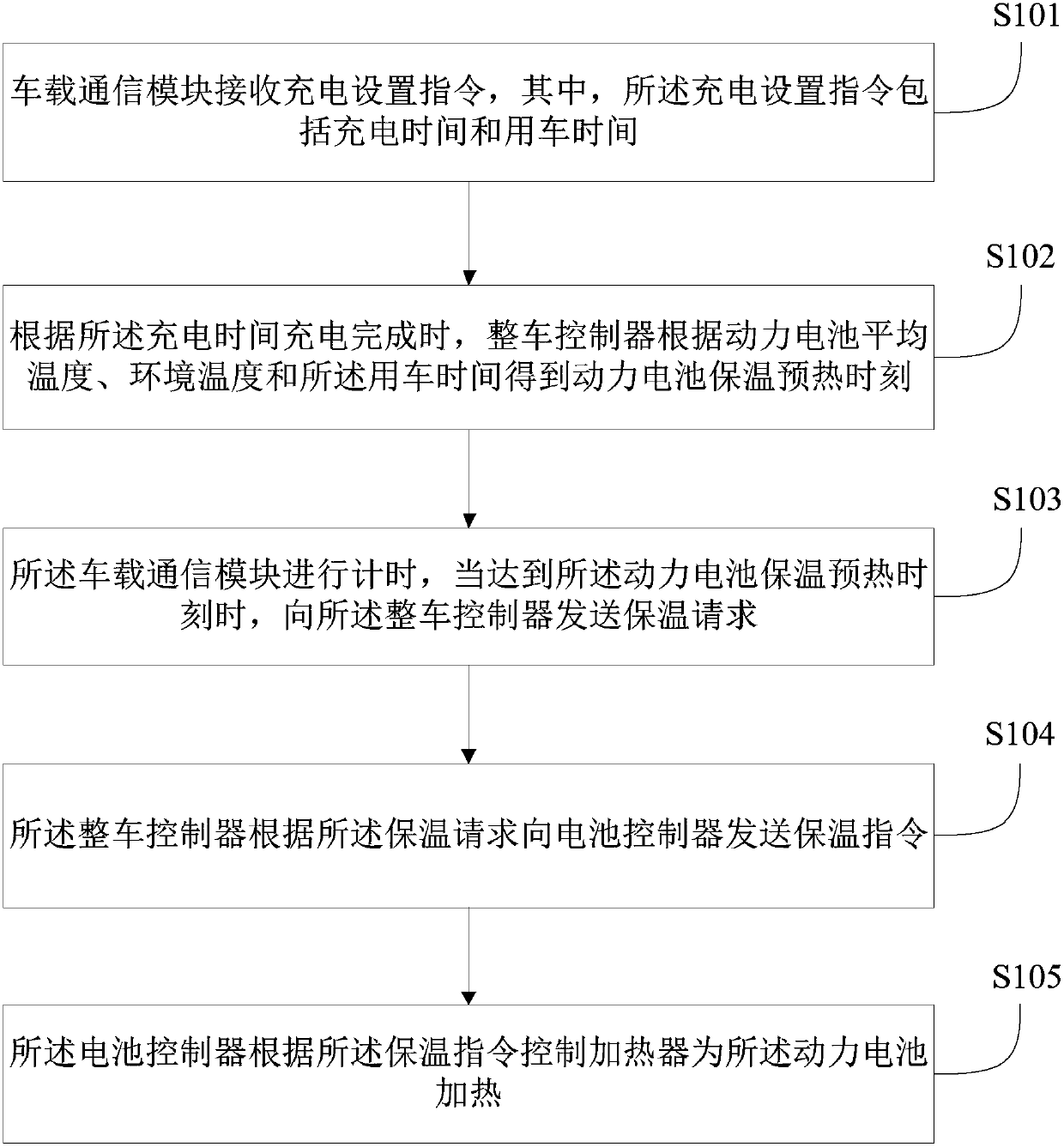

[0032] figure 1 It is a flow chart of a power battery heat preservation control method for an electric vehicle according to an embodiment of the present invention.

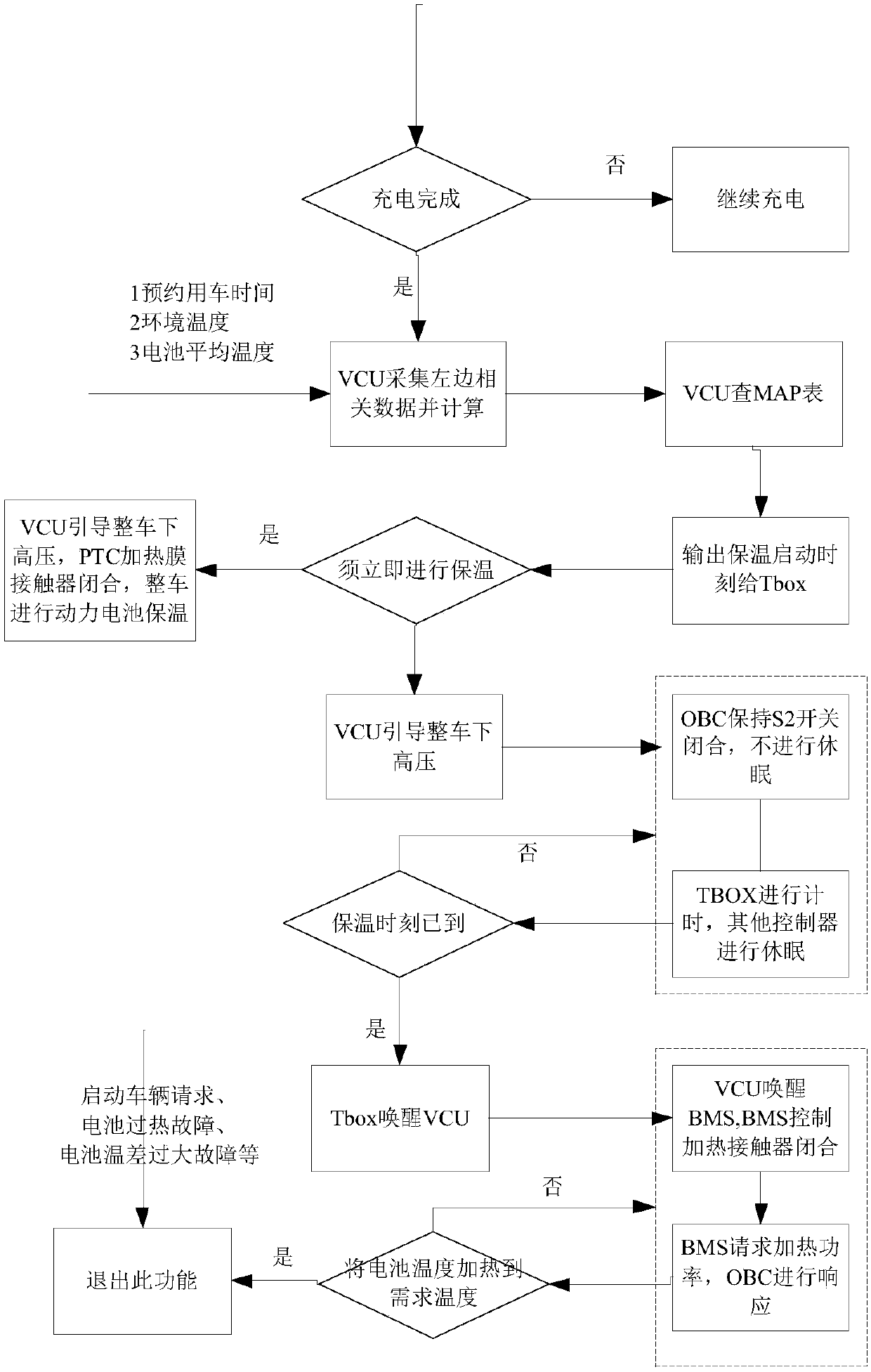

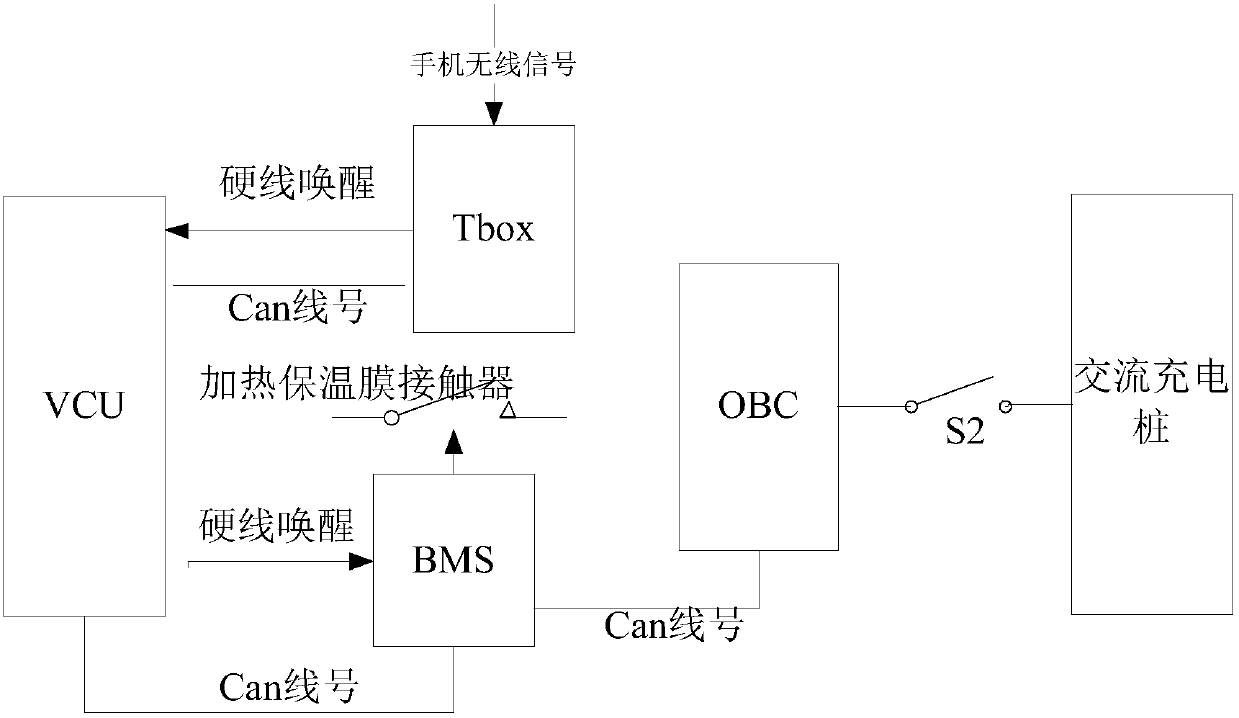

[0033] like figure 1 shown, combined with figure 2 According to an embodiment of the present invention, a power battery heat preservation control method for an electric vehicle includes the following steps:

[0034] S101: The on-vehicle communication module receives a charging setting instruction, wherein the charging setting instruction includes charging time and car usage time.

[0035] The on-vehicle communication module is, for example, the TBOX of the vehicle. As a specific example, the on-vehicle communication mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com