Spherical vector spray pipe

A vector nozzle and nozzle technology, which is applied in the field of aviation model, can solve the problems such as the inability of the nozzle to rotate and poor maneuverability, and achieve the effect of simple structure and improved maneuverability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

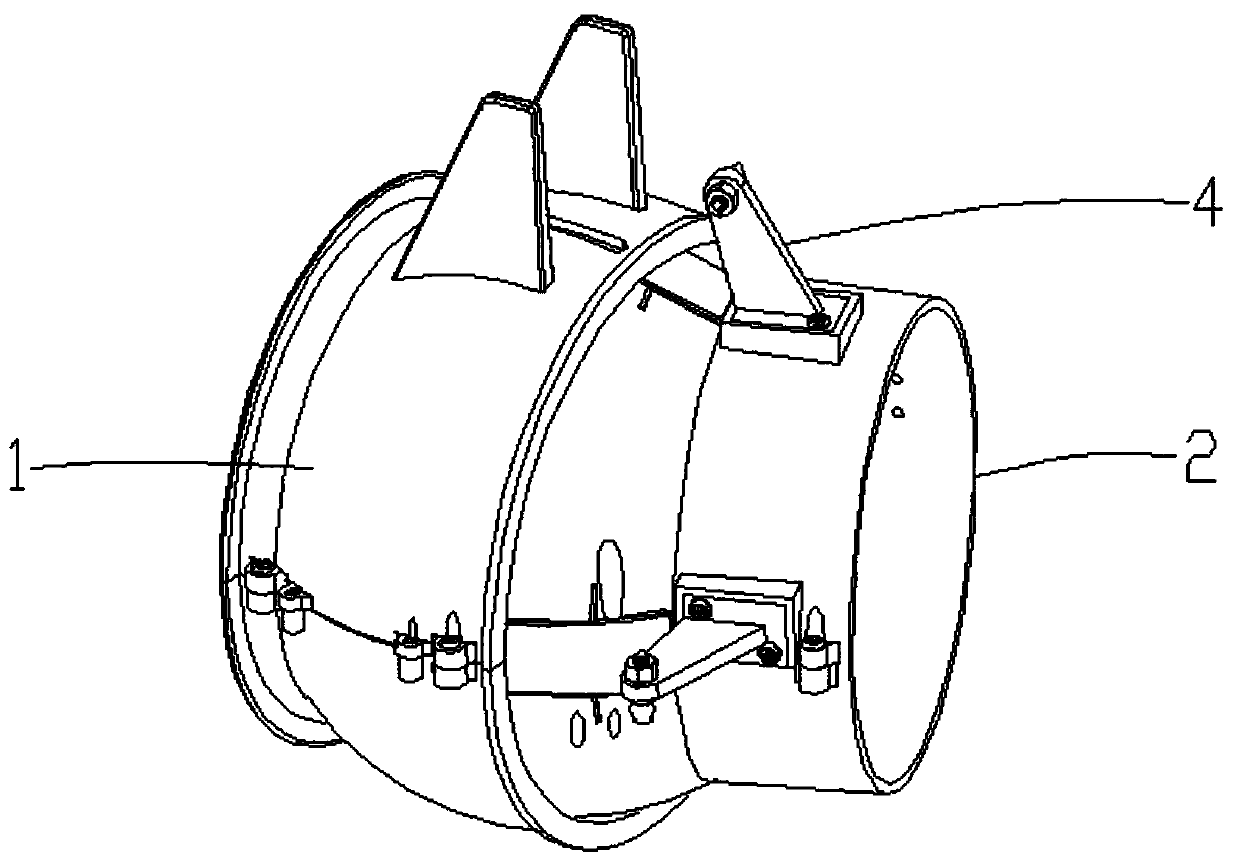

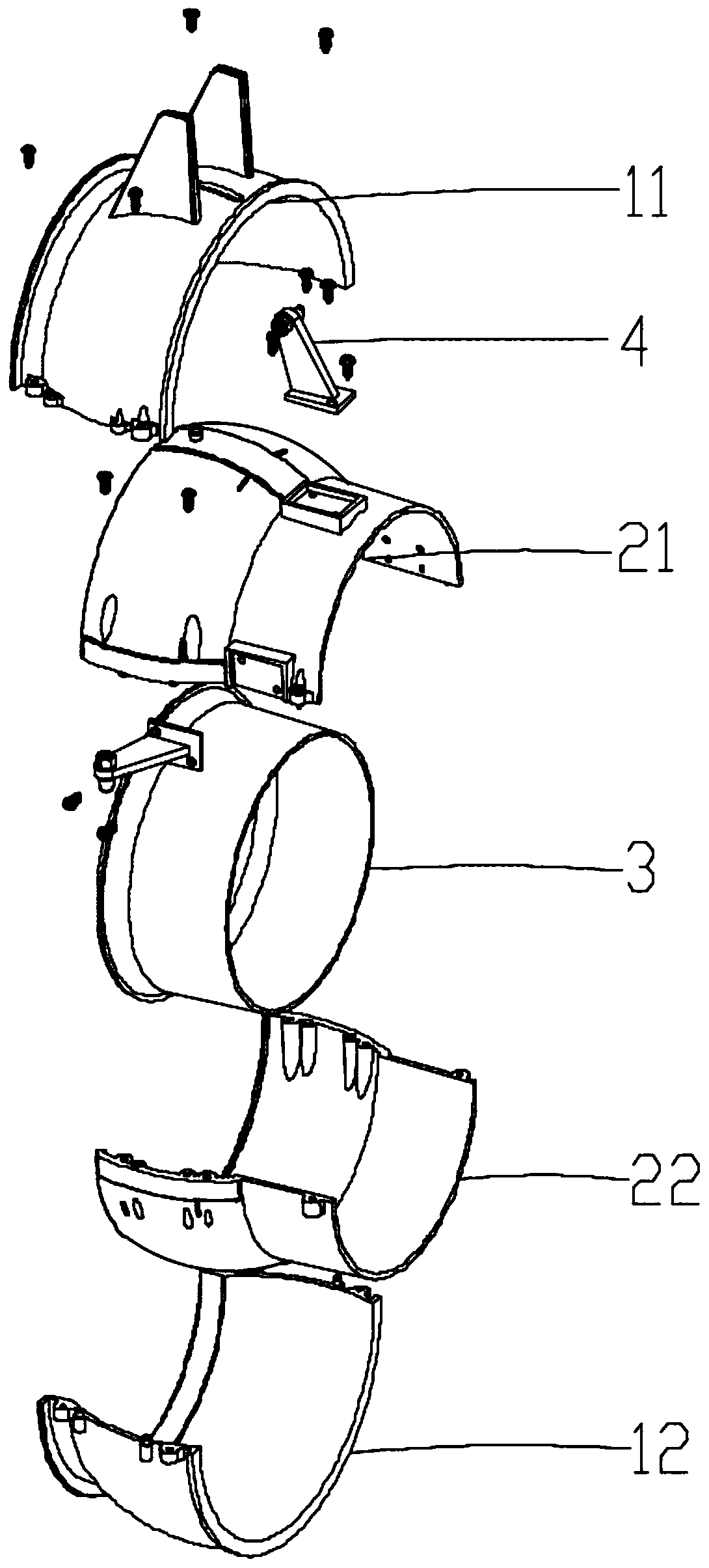

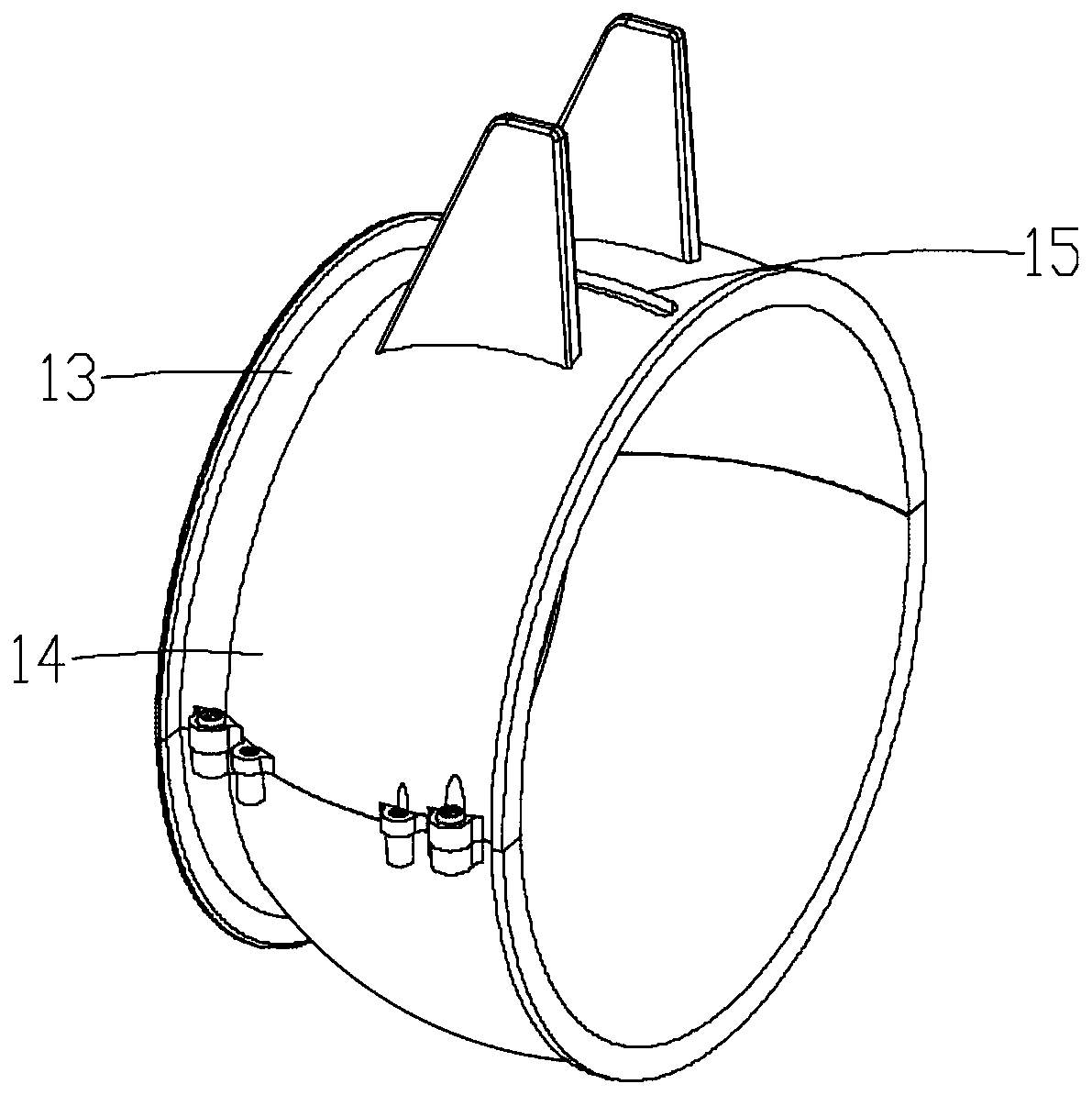

[0019] See Figure 1-7 As shown, the present invention relates to a spherical vector nozzle, which includes a fixed nozzle and a rotating nozzle. The fixed nozzle is used to connect with the jet port and is fixed. The fixed nozzle includes a connecting pipe body and a spherical outer pipe head. The spherical outer pipe head includes a spherical shell structure with two ends passing through, the first end of the connecting pipe body is connected with the exhaust port, the second end of the connecting pipe body is connected with the spherical outer pipe head, and the diameter of the connecting pipe body is Larger than the diameter of the spherical outer pipe head, the fixed nozzle is provided with a first flow passage that penetrates the pipe body and the spherical outer pipe head, and a spherical space is provided in the spherical outer pipe head, and the spherical space has an opening communicating with the first flow passage, A rotating nozzle is provided in the opening, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com