Patents

Literature

33results about How to "Avoid Insufficient Grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

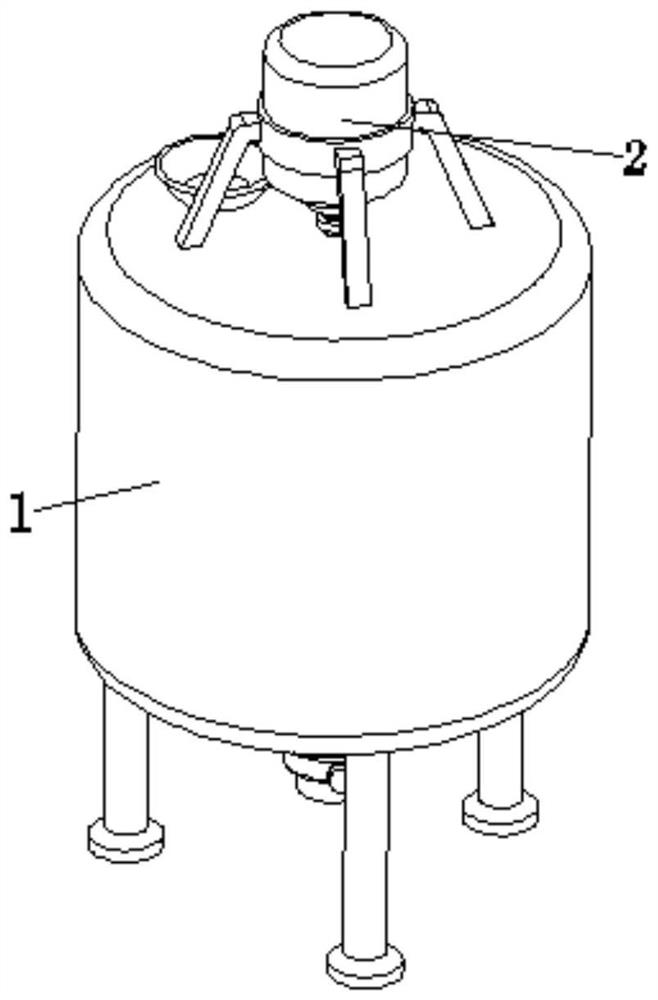

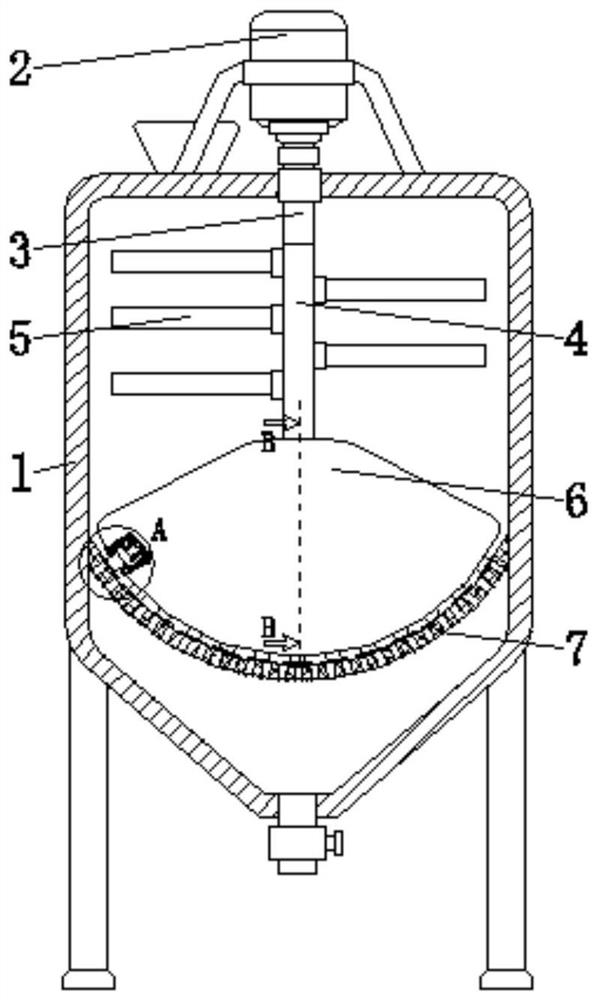

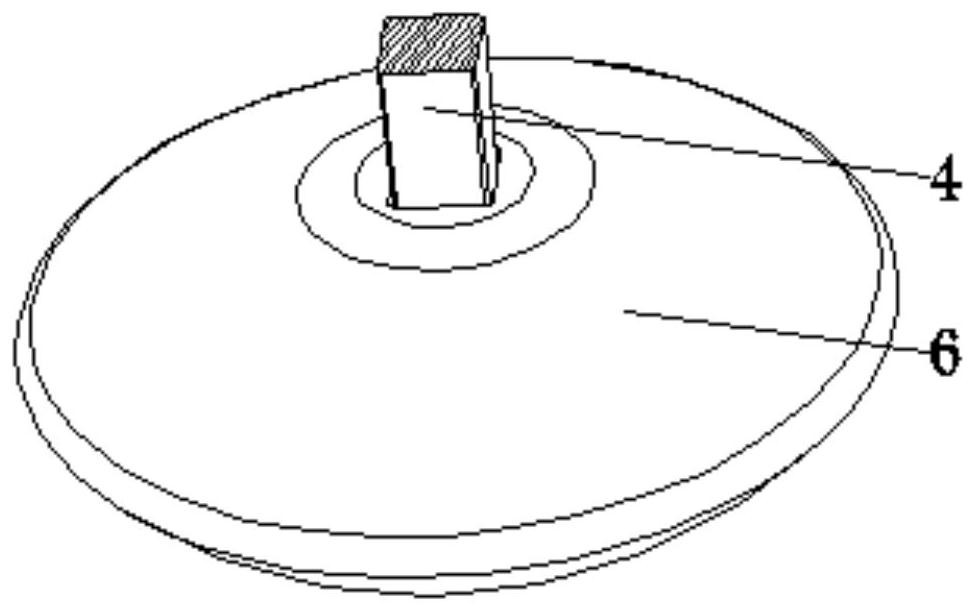

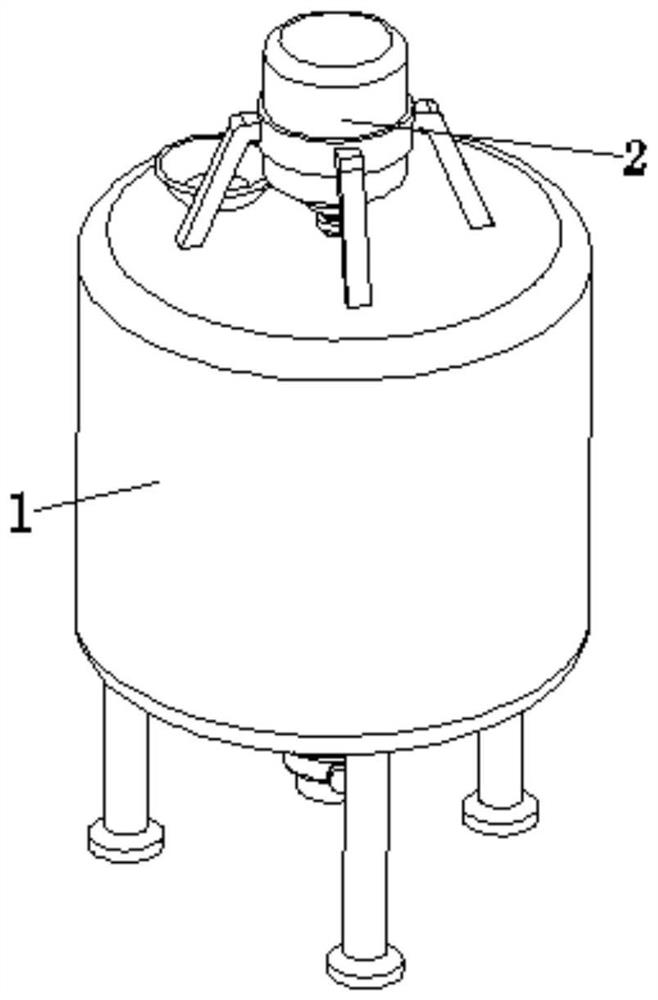

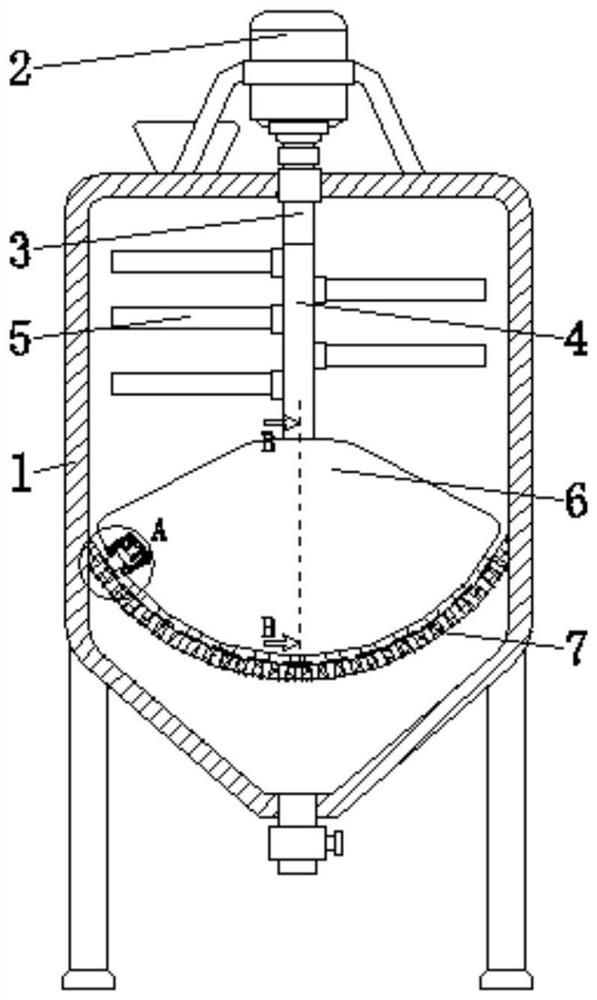

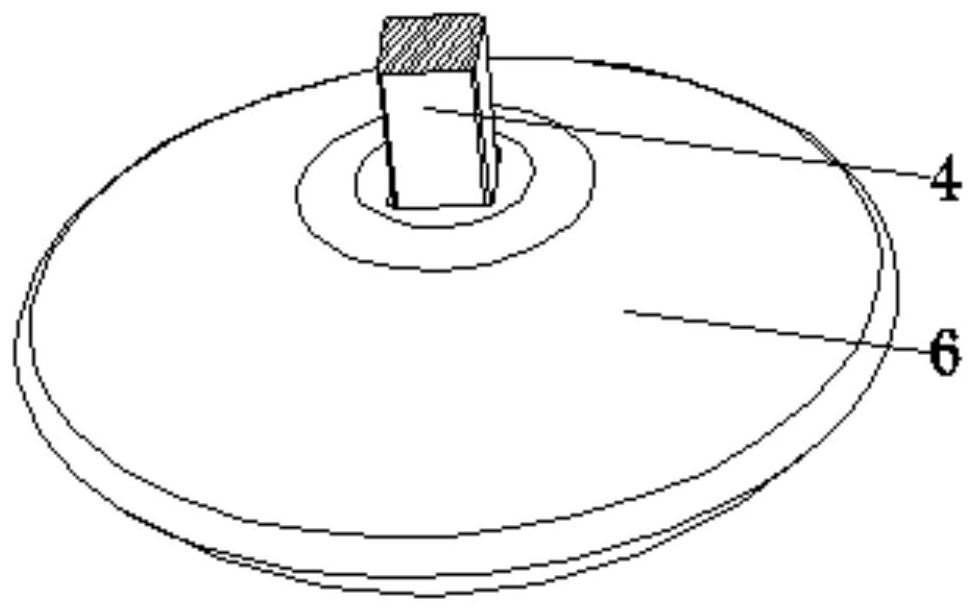

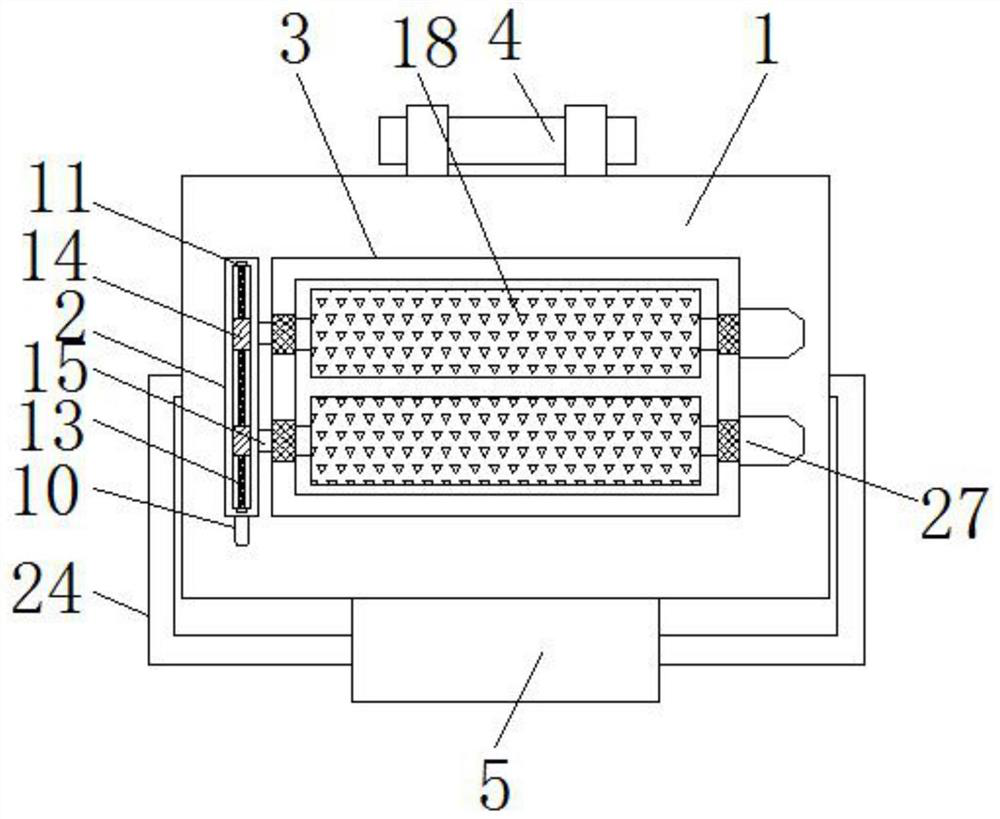

Feed processing equipment

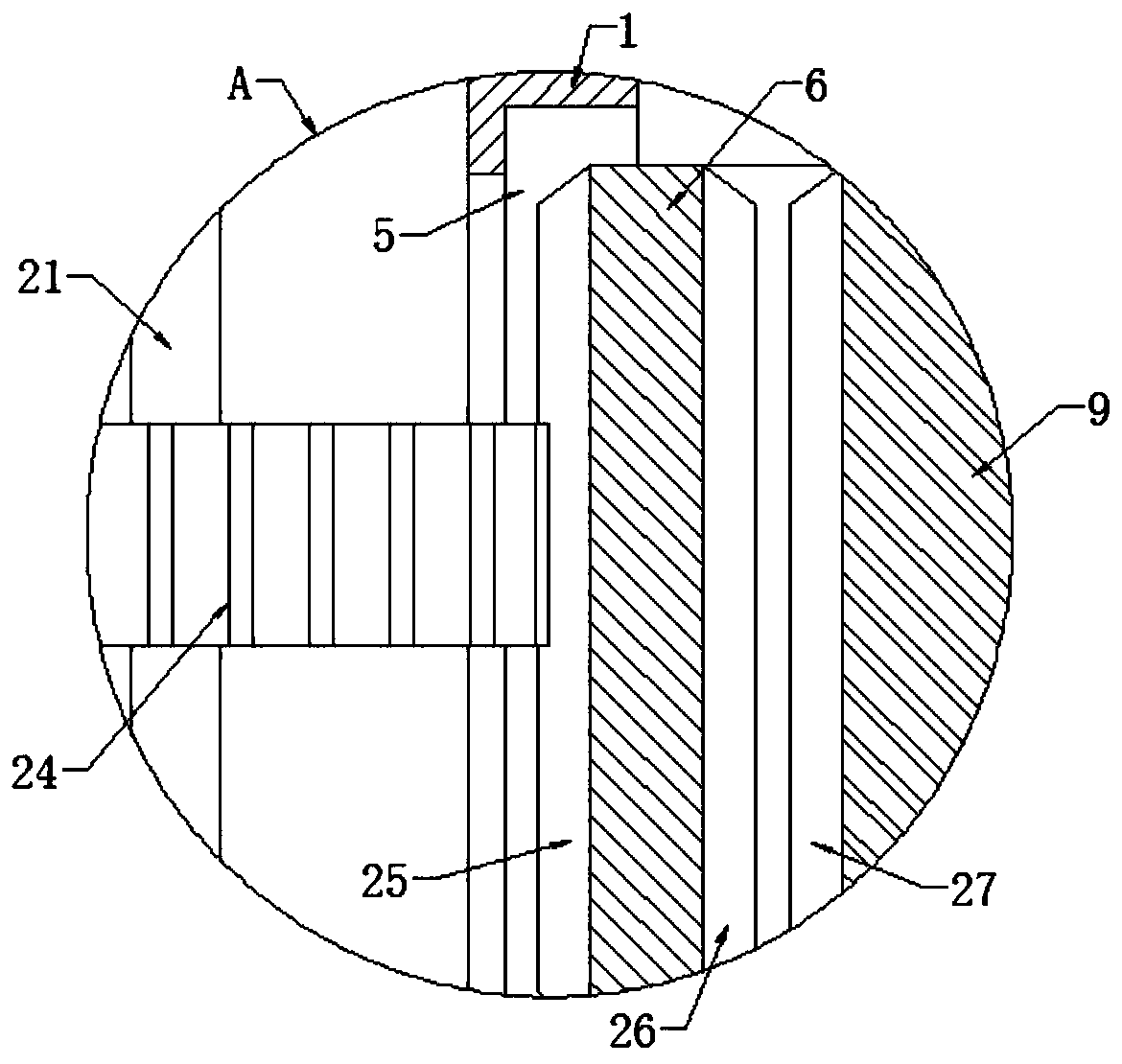

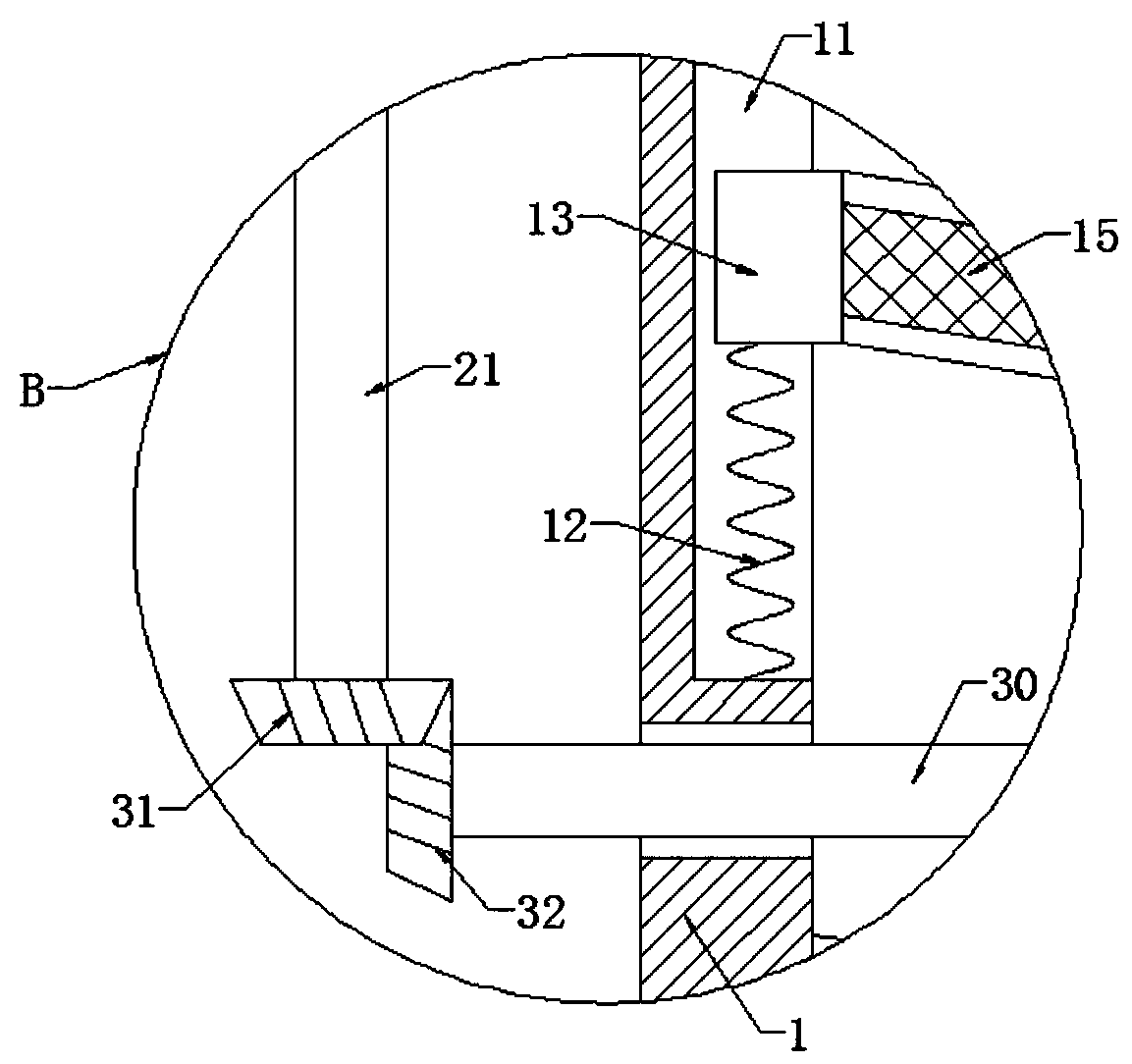

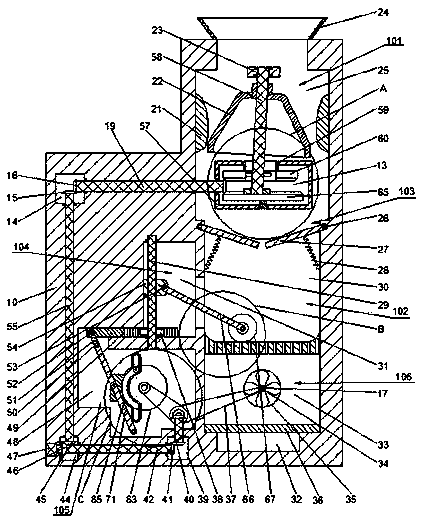

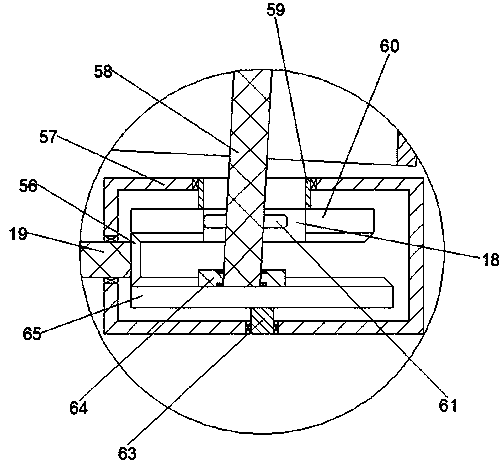

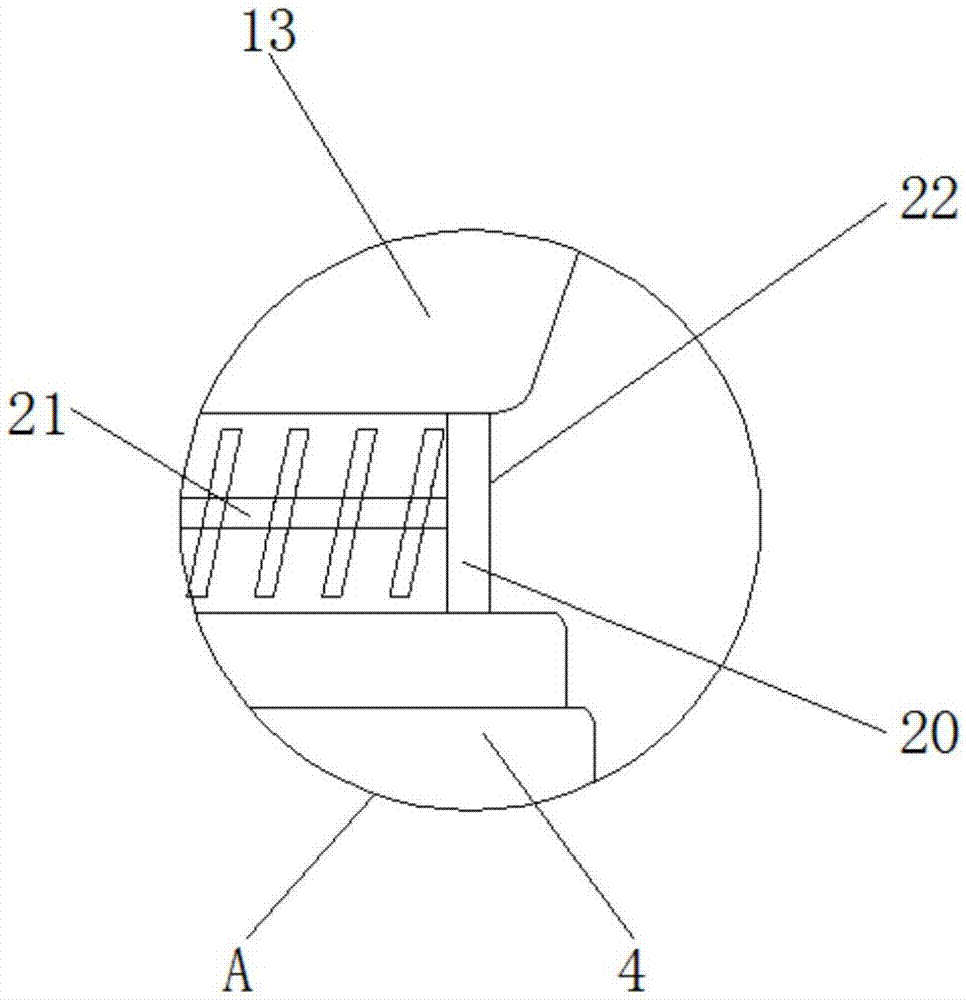

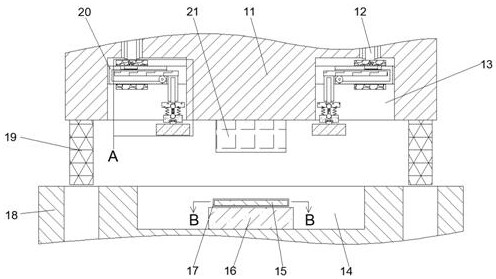

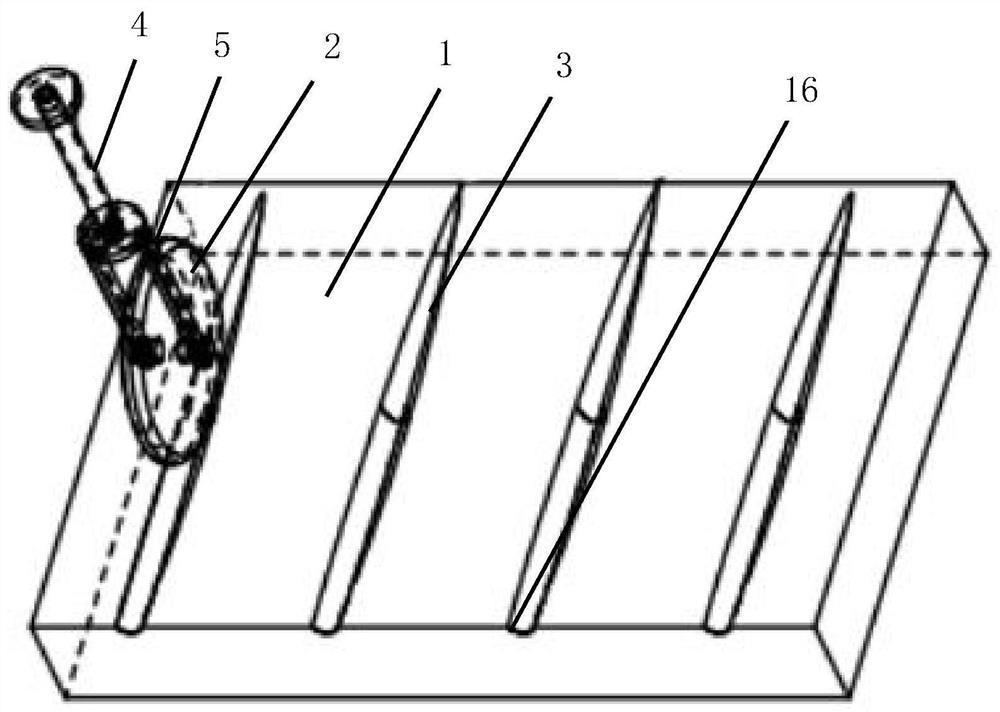

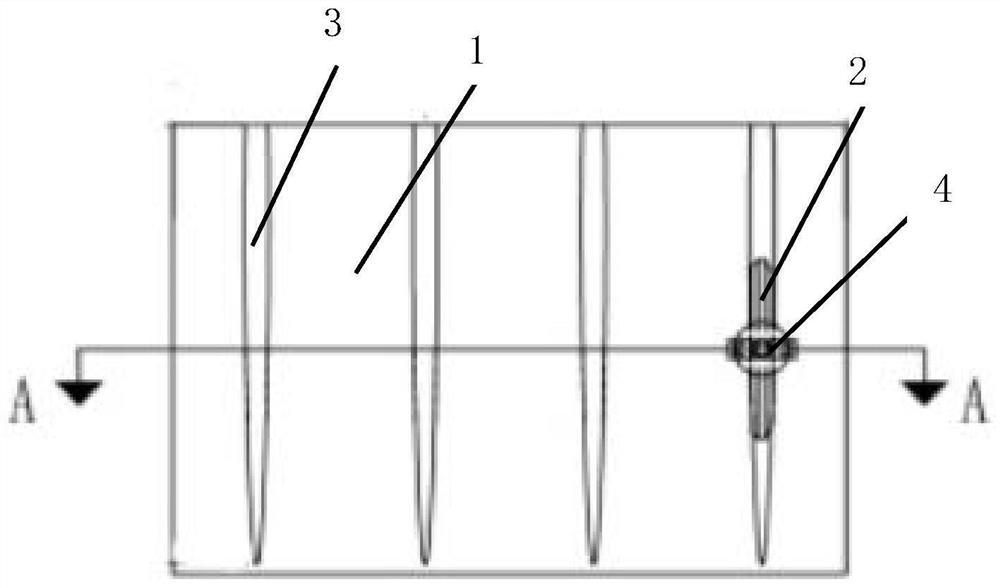

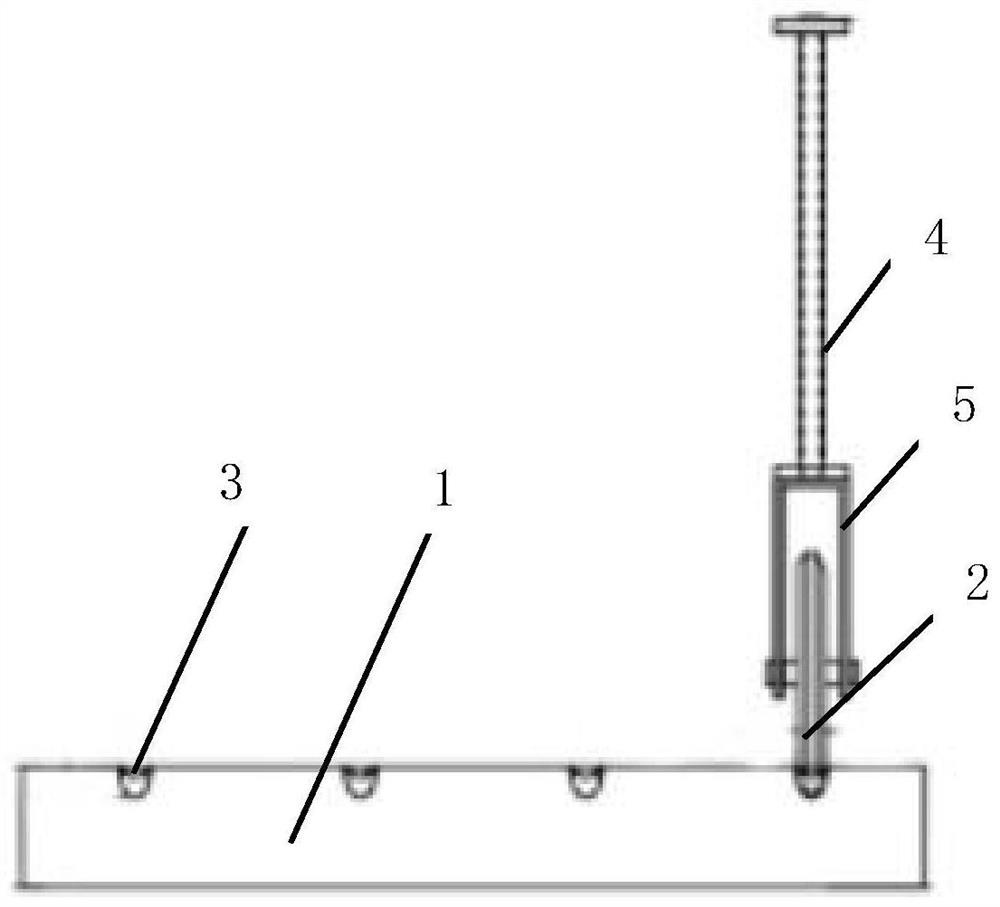

The invention discloses feed processing equipment. The feed processing equipment comprises a grinding tank and a driving motor, wherein a rotating shaft is rotatably connected to the center of the topof the grinding tank; the top end of the rotating shaft is fixedly connected with an output shaft of the driving motor through a coupling; a square connecting rod is fixed to the bottom end of the rotating shaft and located in the center of the interior of the rotating shaft; deflector rods are fixed to the surface of the square connecting rod; a grinding device is arranged at the bottom end of the square connecting rod, the grinding device is in sliding connection with the square connecting rod; and a sieve plate is fixed to the position, close to the bottom of the grinding device, in the grinding tank. The invention relates to the technical field of feed processing. According to the feed processing equipment, the effects of uniform grinding and adhesion prevention are achieved; elasticpressing can be carried out, and the grinding space is automatically and moderately increased, so that large and small granular materials uniformly leak, and grinding is rapid and uniform; and meanwhile, sticky materials on the inner wall can be automatically scraped off, so that the working efficiency and the use performance are improved.

Owner:莱阳和美华饲料有限公司

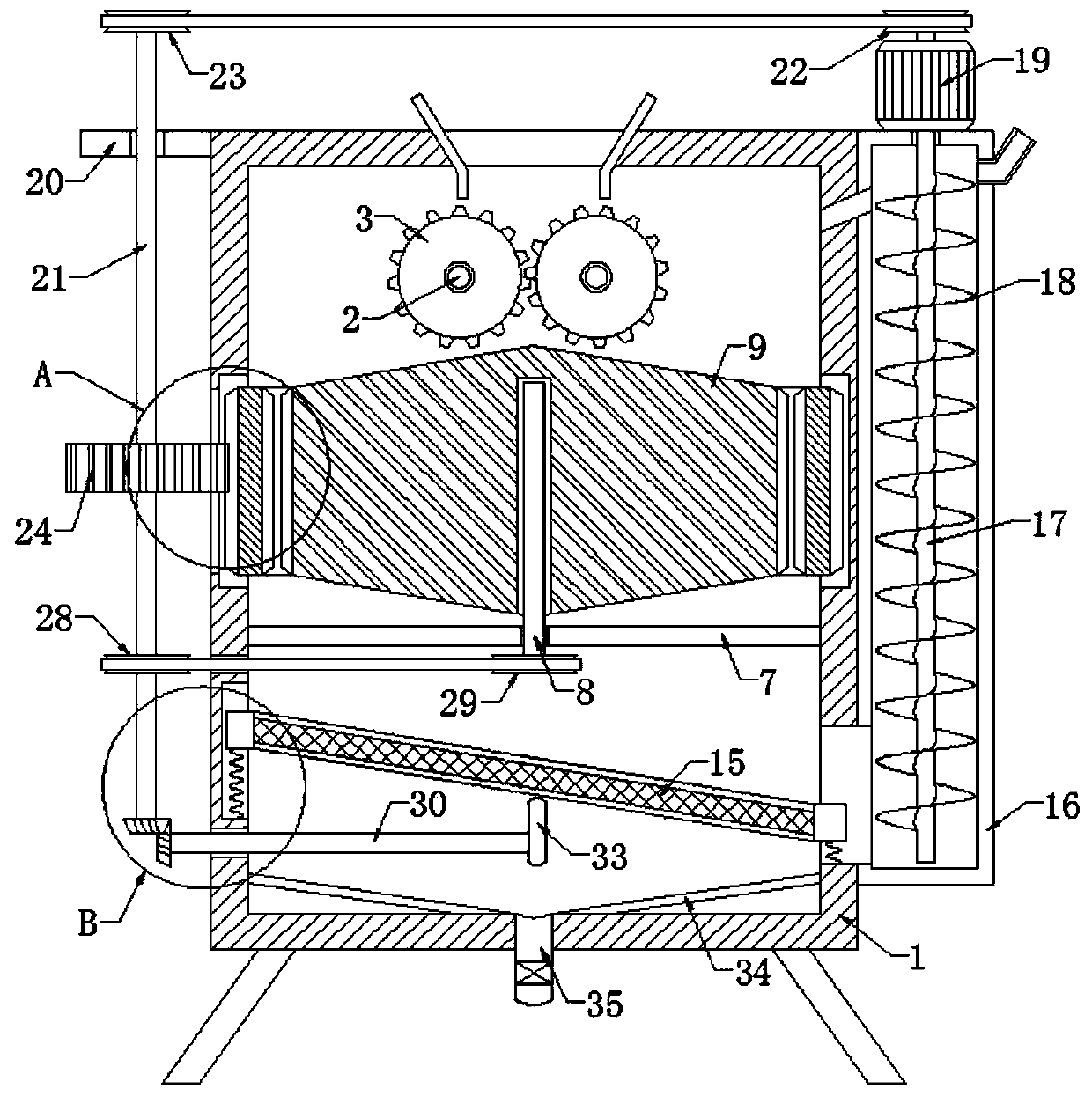

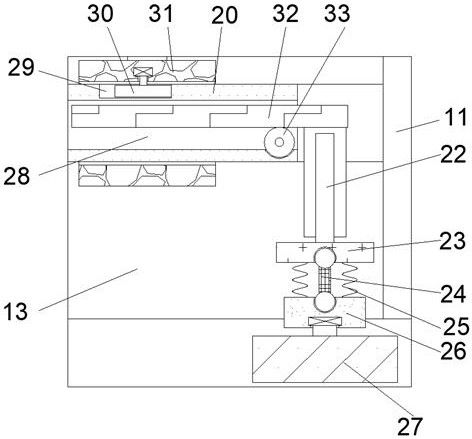

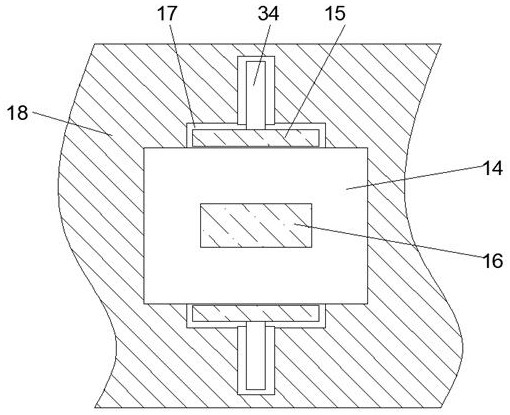

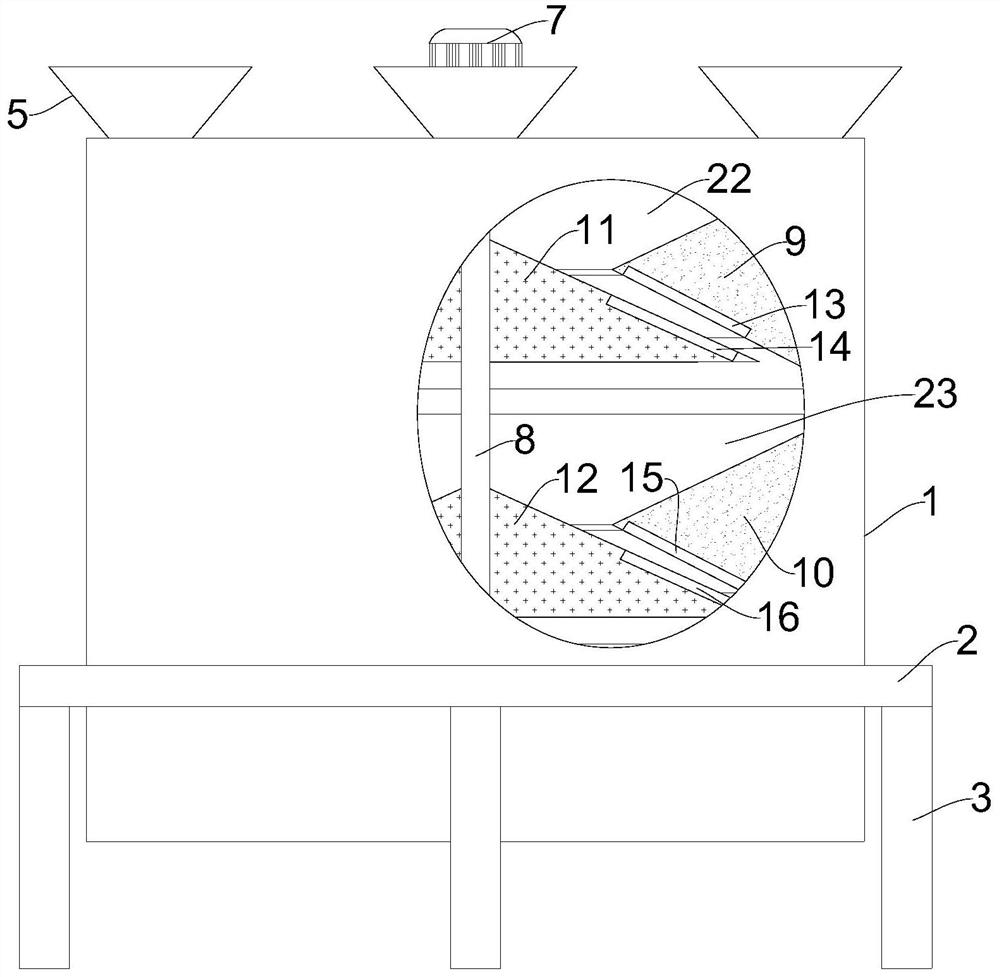

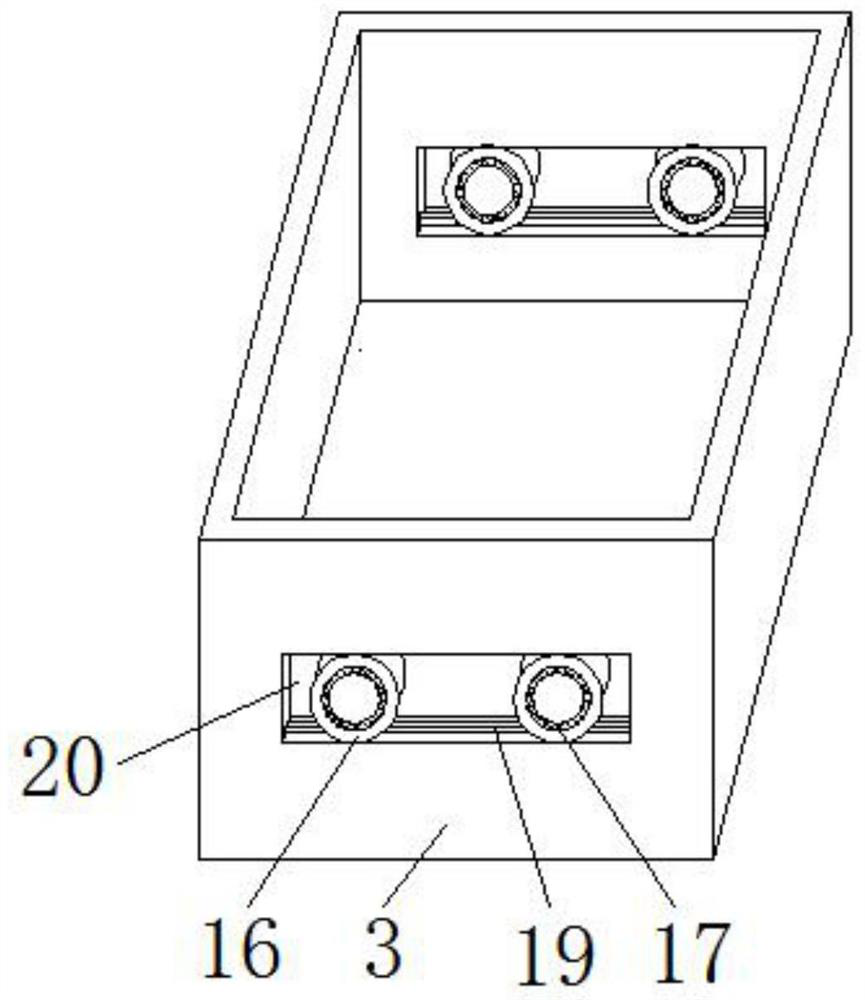

Ball-milling mixer for producing drilling-milling-integration hard alloy

The invention discloses a ball-milling mixer for producing a drilling-milling-integration hard alloy. The ball-milling mixer comprises a barrel, wherein two grinding rollers are rotationally connectedto the upper portion of the inner wall of the barrel through two rotating shafts correspondingly, a first annular groove is formed in the inner wall of the barrel, a first circular ring is slidably connected to the inner wall of the first annular groove, a transverse plate is fixedly connected to the inner wall of the barrel, the upper end of the transverse plate is rotationally connected with acylinder through a connecting rod, and the upper end and the lower end of the cylinder are conical. According to the mixer, by arranging the grinding rollers, first grinding teeth and second grindingteeth, materials can be fully and finely ground, a cam collides with a transverse rod in a clearance mode through rotation of a transverse column, the materials ground again can be filtered, large particles in the ground materials are removed, through rotation of a spiral blade of an auger, the large particles filtered by a filter screen can be conveyed, manual conveying of the large particles isnot needed, and the working intensity is reduced.

Owner:北京享云智汇科技有限公司

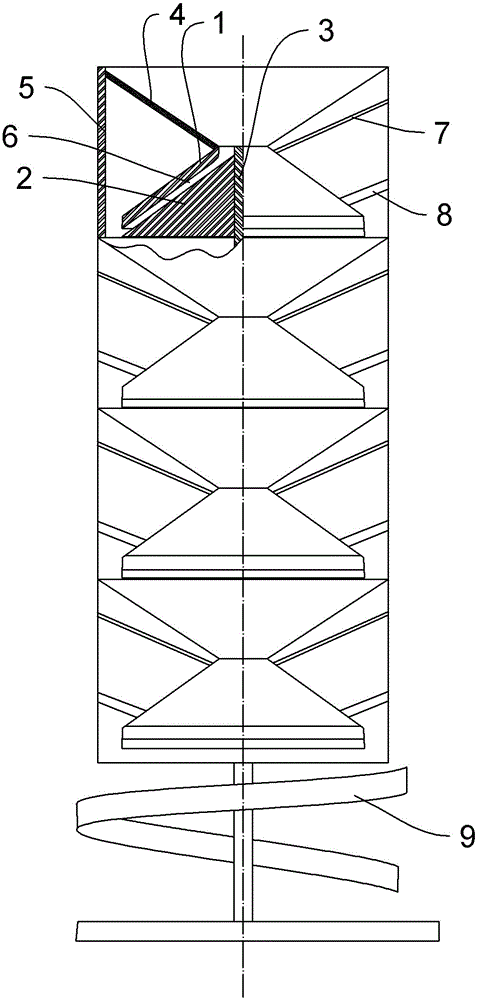

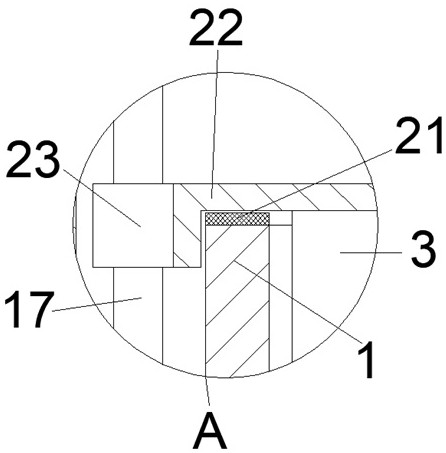

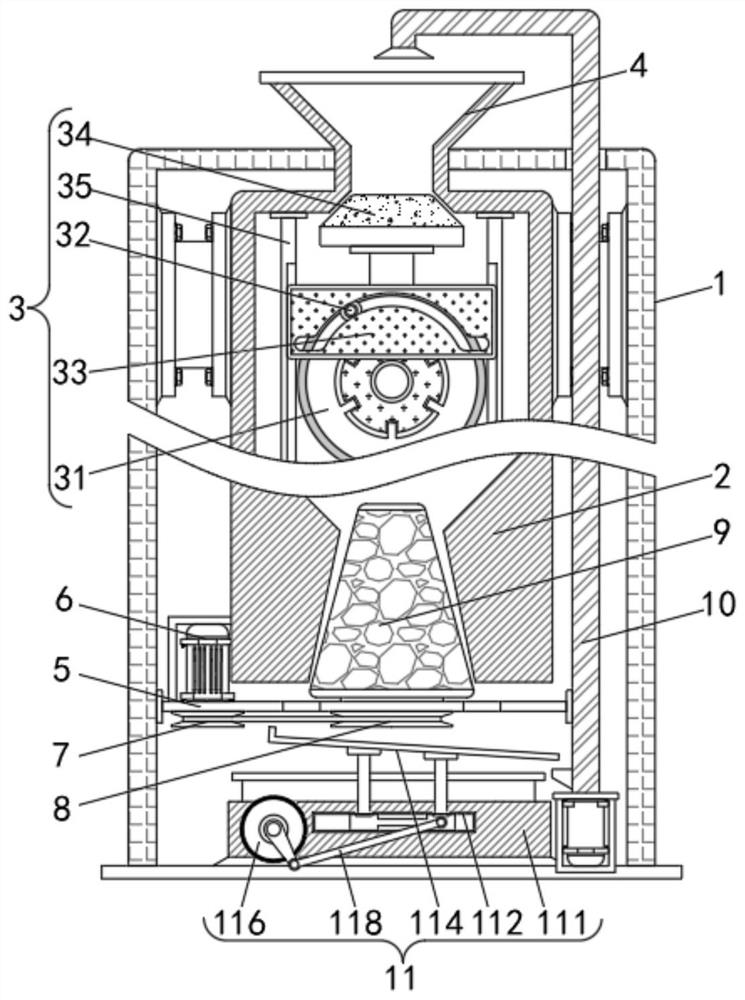

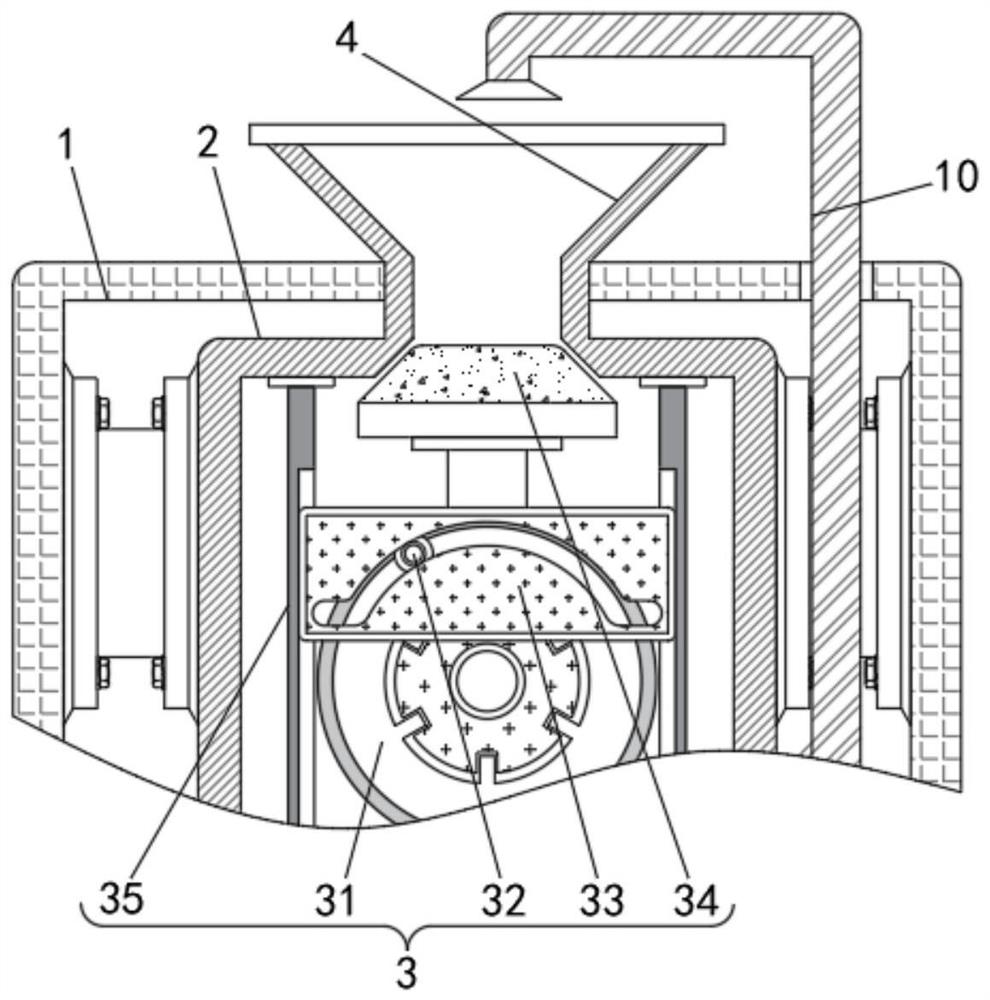

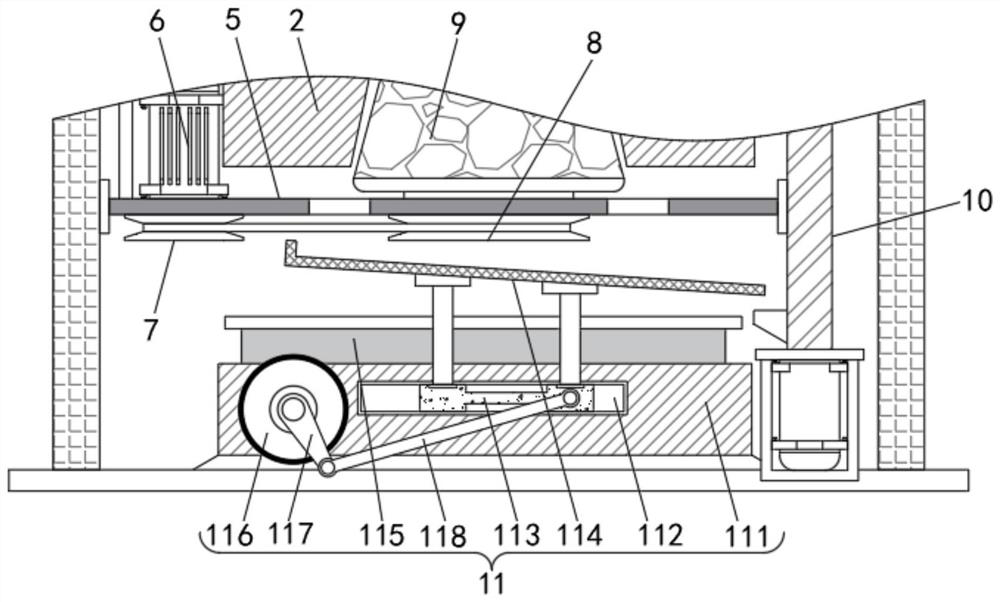

Grinding device for chemical processing of materials

InactiveCN110882816AAvoid insufficient grindingImprove quality and efficiencyGrain treatmentsEngineeringCrusher

The invention discloses a grinding device for chemical processing of materials. The grinding device comprises a base body and a fixing block, wherein the fixing block is internally provided with a transmission groove with an upward opening, the base body is internally provided with a crushing cavity with an upward opening, the crushing cavity is internally provided with a crushing mechanism, a fine grinding cavity communicating with the crushing cavity is formed under the crushing cavity, the fine grinding cavity is internally provided with a fine grinding mechanism, and storage mechanisms arearranged at the wall body positions, located at the left end and the right end, of the fine grinding cavity. A driven cavity communicating with the fine grinding cavity is formed in the left side ofthe fine grinding cavity, the driven cavity is internally provided with a driven mechanism, a driving cavity is formed below the driven cavity, the driving cavity is internally provided with a drivingmechanism, an aggregate cavity is formed in the right side of the driving cavity, the aggregate cavity is internally provided with an aggregate mechanism, a first rectangular groove is formed below the driving cavity, a second rectangular groove is formed in the left side of the first rectangular groove, and a first rotating shaft is rotatably installed between the second rectangular groove and the first rectangular groove.

Owner:东阳鸿松机械科技有限公司

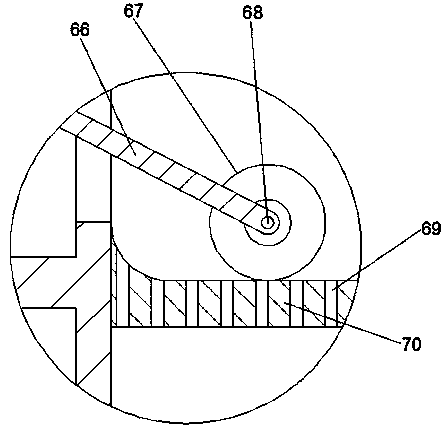

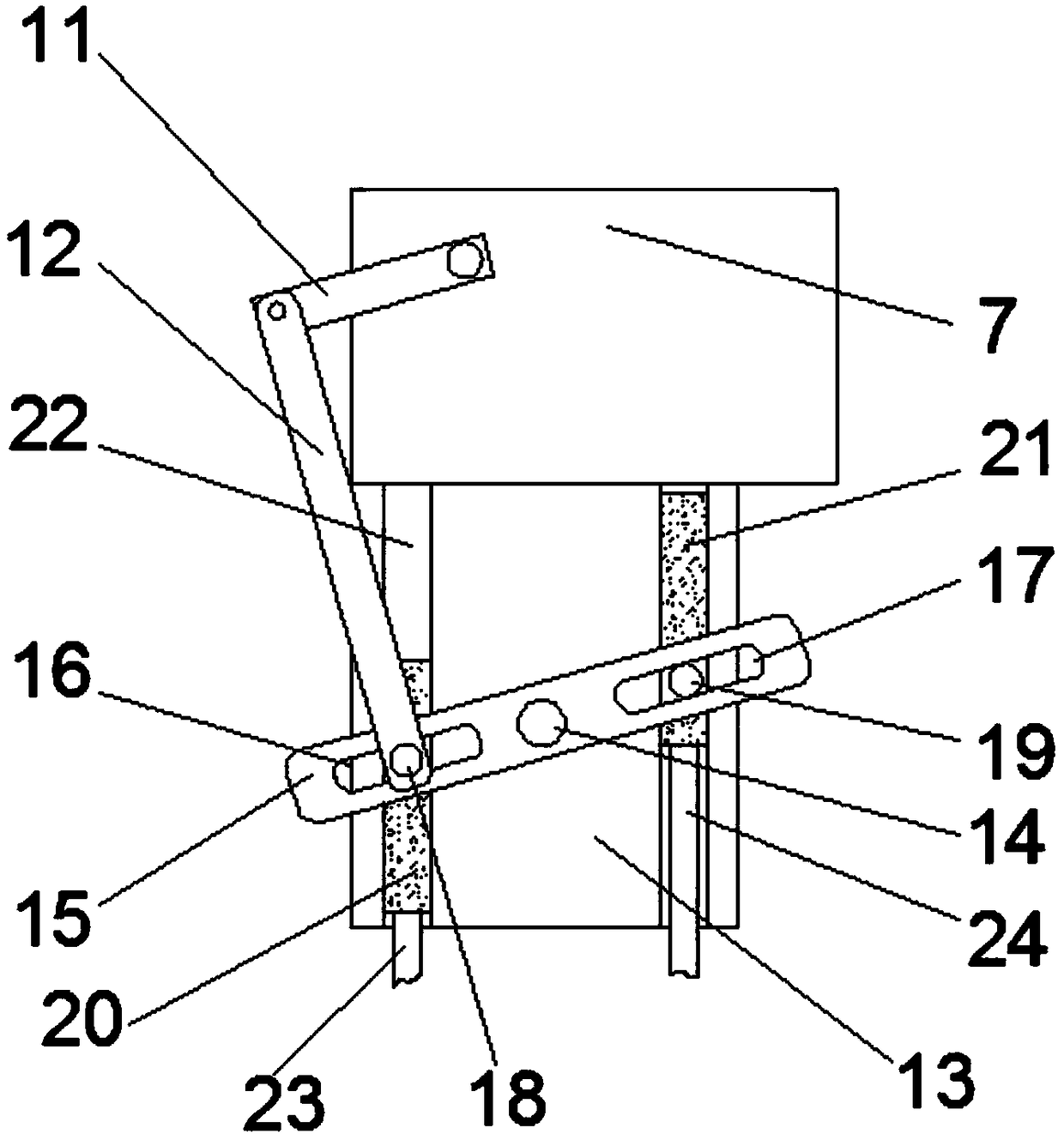

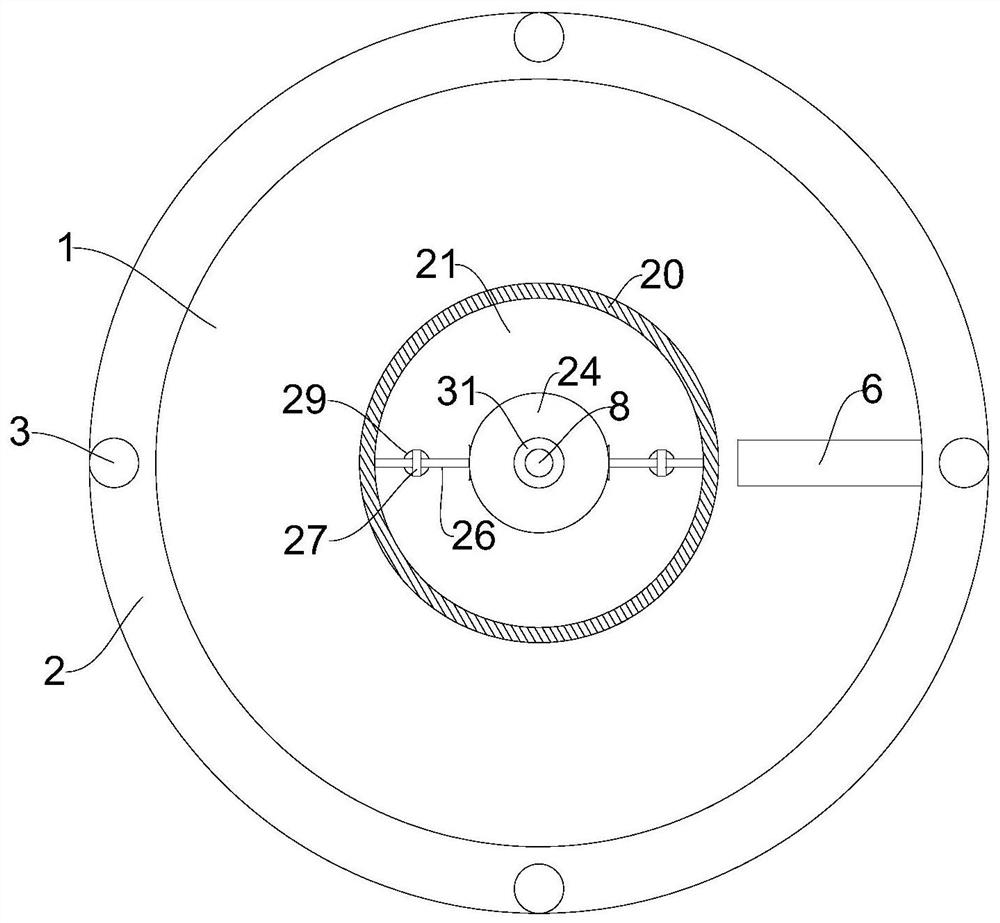

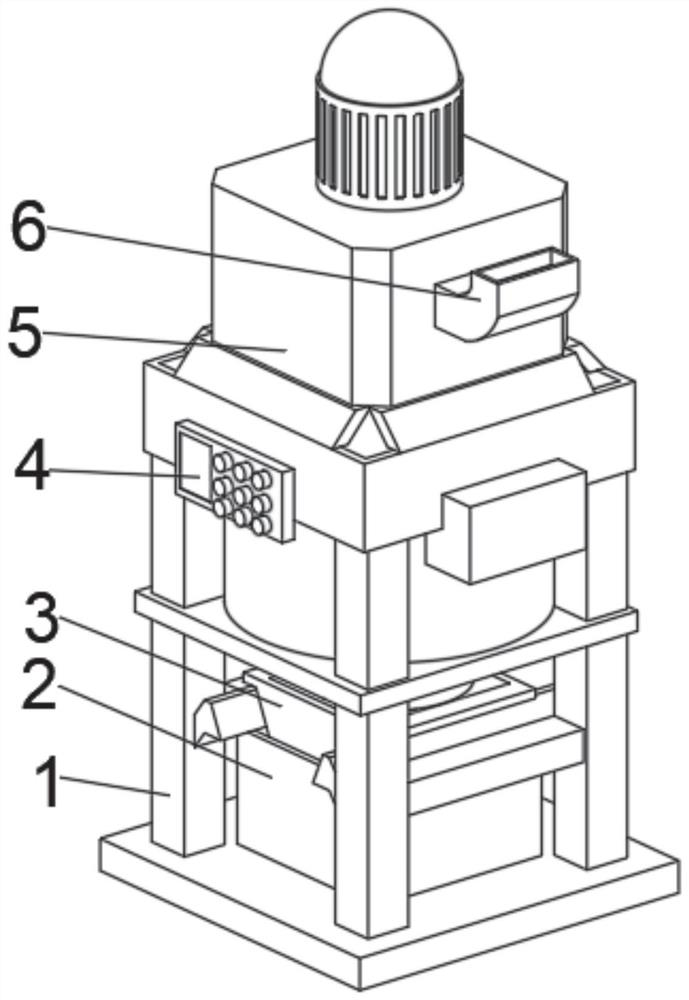

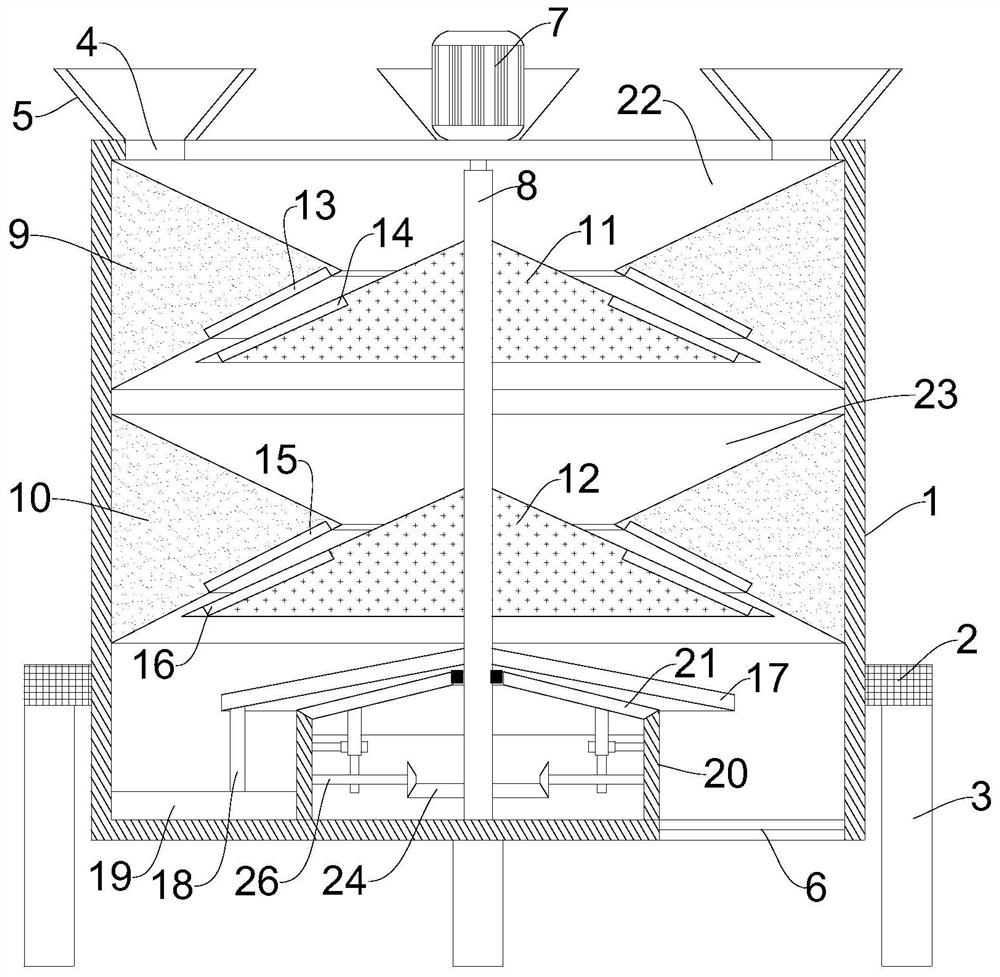

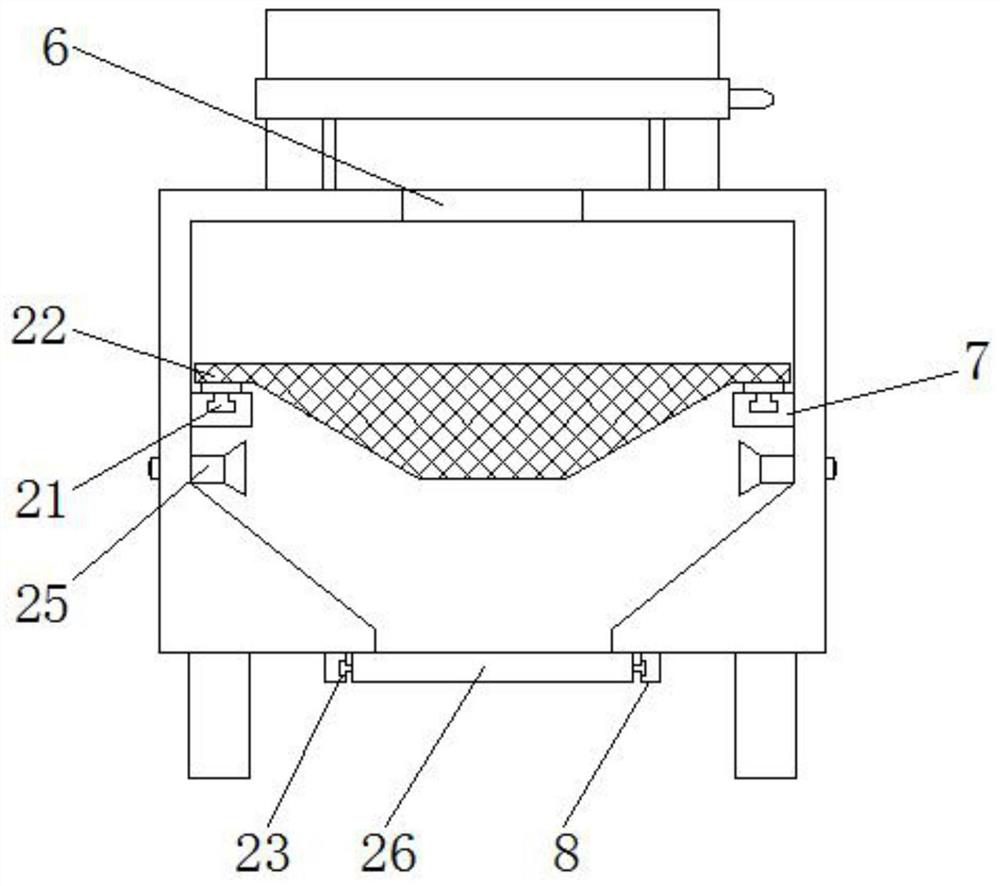

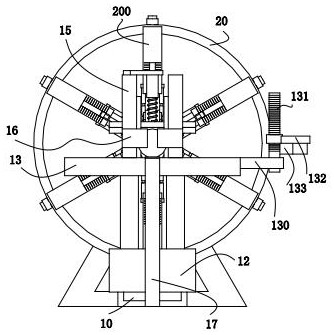

Classified grinding device

InactiveCN105107600AAvoid insufficient grindingImprove stabilityGrain treatmentsEngineeringFunnel shape

The invention relates to medicine grinding equipment, in particular to a classified grinding device. The classified grinding device comprises a vertically arranged rotating drum. A fixing shaft is coaxially arranged in the rotating drum, and grinding mechanisms are arranged between the fixing shaft and the rotating drum. Each grinding mechanism comprises a movable grinding piece and a fixed grinding piece, wherein each fixed grinding piece is conical, and the fixed grinding pieces are coaxial with the fixing shaft. The fixed grinding pieces are arranged on the fixing shaft in a sleeving mode and fixedly connected with the fixing shaft, and material channels are arranged between the fixed grinding pieces and the rotating drum; each movable grinding piece is conical, and a conical cavity matched with the corresponding fixed grinding piece is formed in each movable grinding piece; the movable grinding pieces are fixedly connected with the rotating drum, feeding inlets are formed in the tops of the movable grinding pieces, and funnel-shaped guiding hoppers are arranged on the tops of the movable grinding pieces; the vertical projective plane of each guiding hopper is larger than that of the corresponding fixed grinding piece; the multiple grinding mechanisms are provided, and grinding gaps between the movable grinding pieces and the fixed grinding pieces are gradually reduced from top to bottom. The classified grinding device has the beneficial effect that the production efficiency is improved.

Owner:CHONGQING KANGLE PHARMA

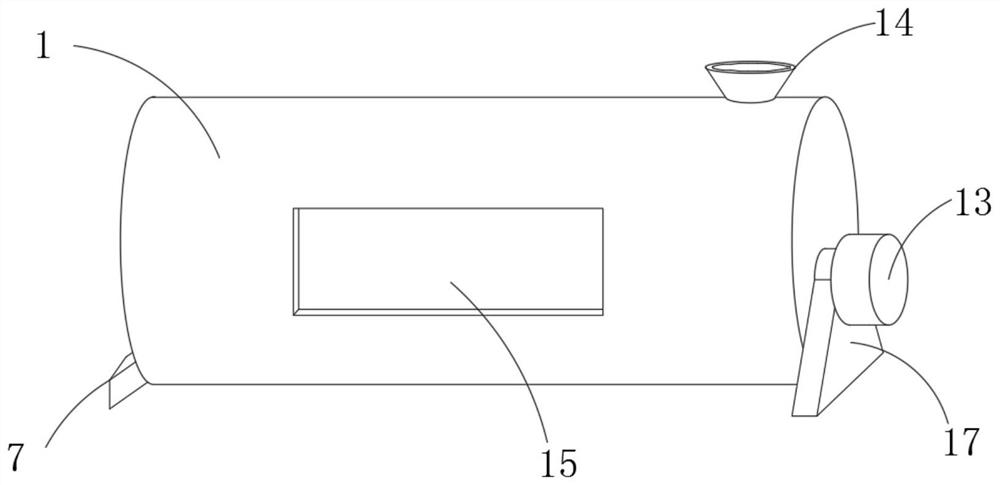

Furnace slag grinding device easy to clean

The invention discloses an easy-to-clean slag grinding device, comprising a first support base and a second support base, the lower surfaces of the first support base and the second support base are connected with vibration damping plates, and the first support base and the upper surface of the second support base are connected with a support column, the upper surface of the second support base is equipped with a drive motor, and the front end of the drive motor is set on the connecting frame, and the outer surface of the front end of the drive motor is nested with The first gear and the second gear, and the first gear and the second gear are respectively connected with the grinding cylinder and the scraper through the third gear and the fourth gear, and the left and right ends of the grinding cylinder are respectively connected with a feeding drum and a The discharge drum is provided with a feed groove at the upper end of the feed drum. The easy-to-clean slag grinding device adopts the design of scraper, partition net, dustproof cover and second bearing, which can scrape off the slag adhered to the inner wall of the grinding cylinder in real time, and prevent it from becoming difficult to remove after long-term accumulation.

Owner:开阳浩洋环保科技开发有限公司

Device used for deburring of stamping workpiece

InactiveCN112935843AAvoid manual grindingAvoid scratchesEdge grinding machinesOther manufacturing equipments/toolsEngineeringMachine

The invention relates to the technical field of machine tools, in particular to a device used for deburring of a stamping workpiece. The device comprises a moving block, a stamping block is fixedly arranged at the lower end of the moving block, a buffer block is fixedly arranged at the lower end of the moving block, a base is fixedly arranged on the lower side of the buffer block, a stamping cavity with an upward opening is formed in the base, and a die block is fixedly arranged in the stamping cavity. Burrs on the periphery of the stamping workpiece are rotationally ground out through a clamping device and a grinding disc, then fingers are prevented from being scratched by the burrs when people take out the workpiece, manual grinding removal to the burrs by people in the later period is avoided, the burrs at different positions of the workpiece are fully ground to be removed through a fine adjustment device and a bearing plate, and the condition of insufficient grinding removal is avoided.

Owner:潍坊江仿机械设备销售有限公司

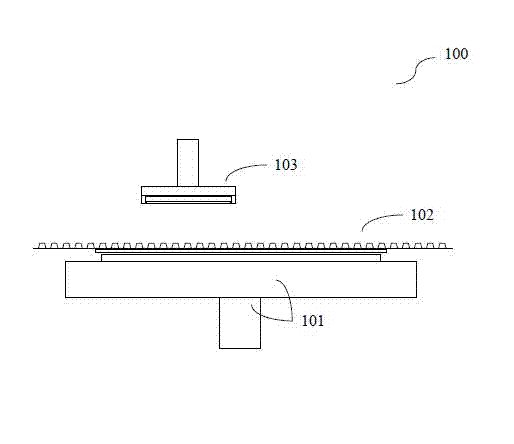

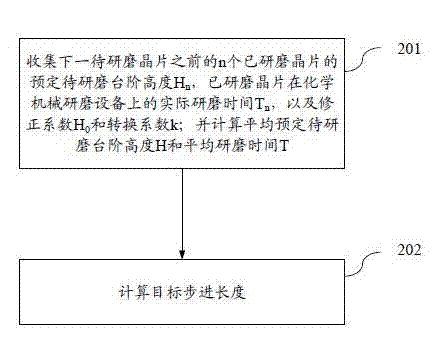

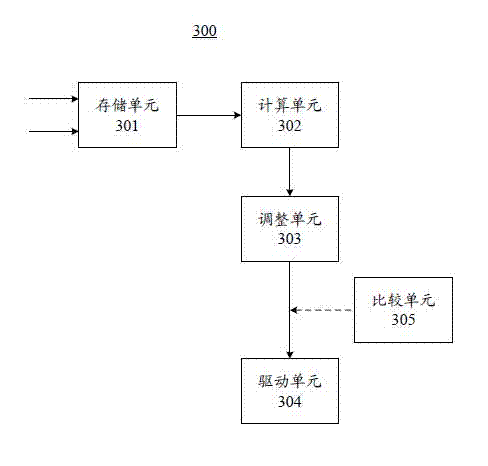

Method for reducing memory effect of chemical mechanical grinding equipment of fixed abrasive particles

ActiveCN102452040AReduce memory effectImprove use valueSemiconductor/solid-state device manufacturingLapping machinesMemory effectConversion coefficients

The invention relates to a method for reducing the memory effect of chemical mechanical grinding equipment of fixed abrasive particles. The method comprises the following steps of: a) collecting the preset to-be-ground step height Hn of n ground wafers before the next to-be-ground wafer, the actual grinding time Tn, a correction coefficient H0 and a conversion coefficient k; and calculating the average preset to-be-ground step height H and average grinding time T of the ground wafers respectively; and b) calculating a target stepping length IR of the next to-be-ground wafer by a grinding pad according to the following calculation model: IR=k.T(H0+H) / 103. The method provided by the invention avoids the conditions of insufficient grinding of the next to-be-ground wafer due to the insufficient abrasive particles on the grinding pad or excessive grinding and waste caused by excessive abrasive particles, and thus reduces the memory effect of chemical mechanical grinding of the fixed abrasive particles, and improves the grinding rate and consistency of wafers with the wafer thickness.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

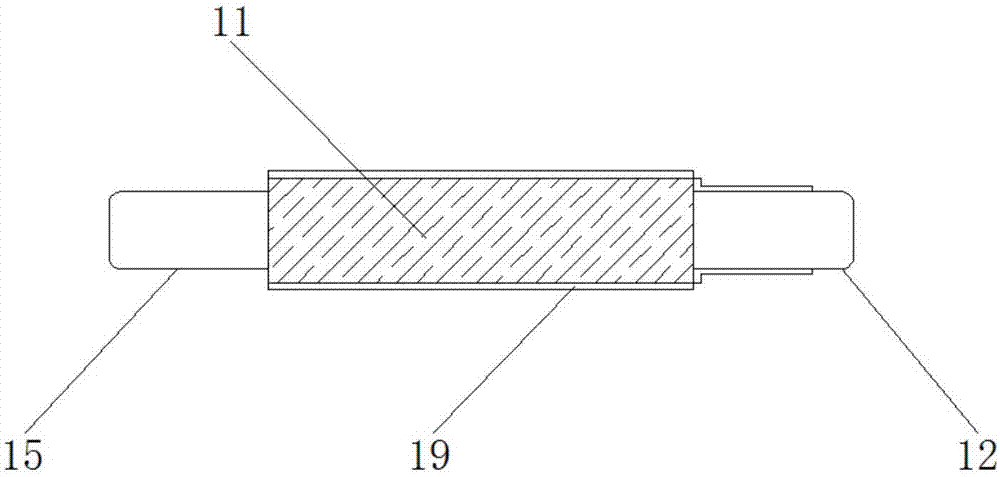

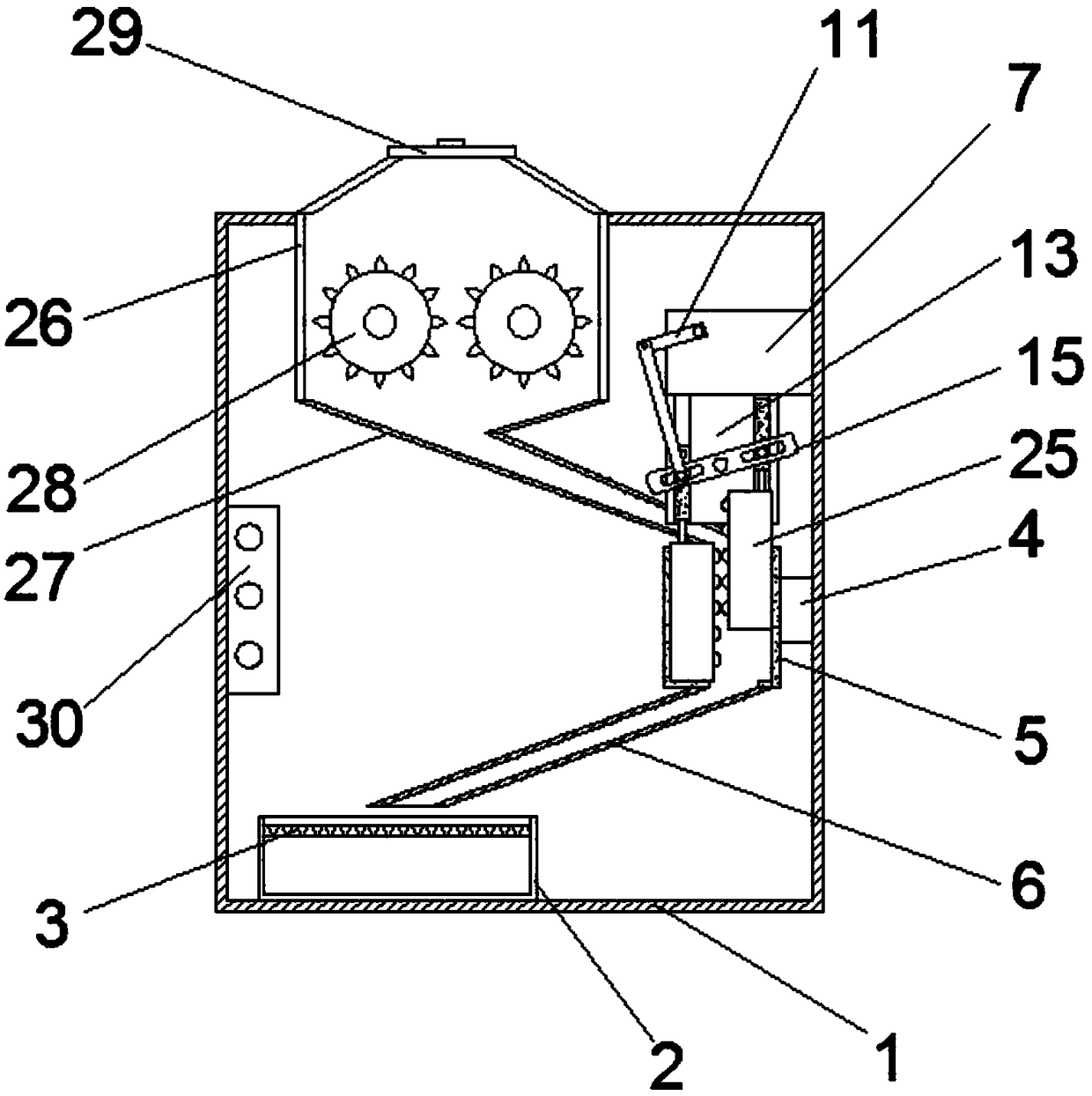

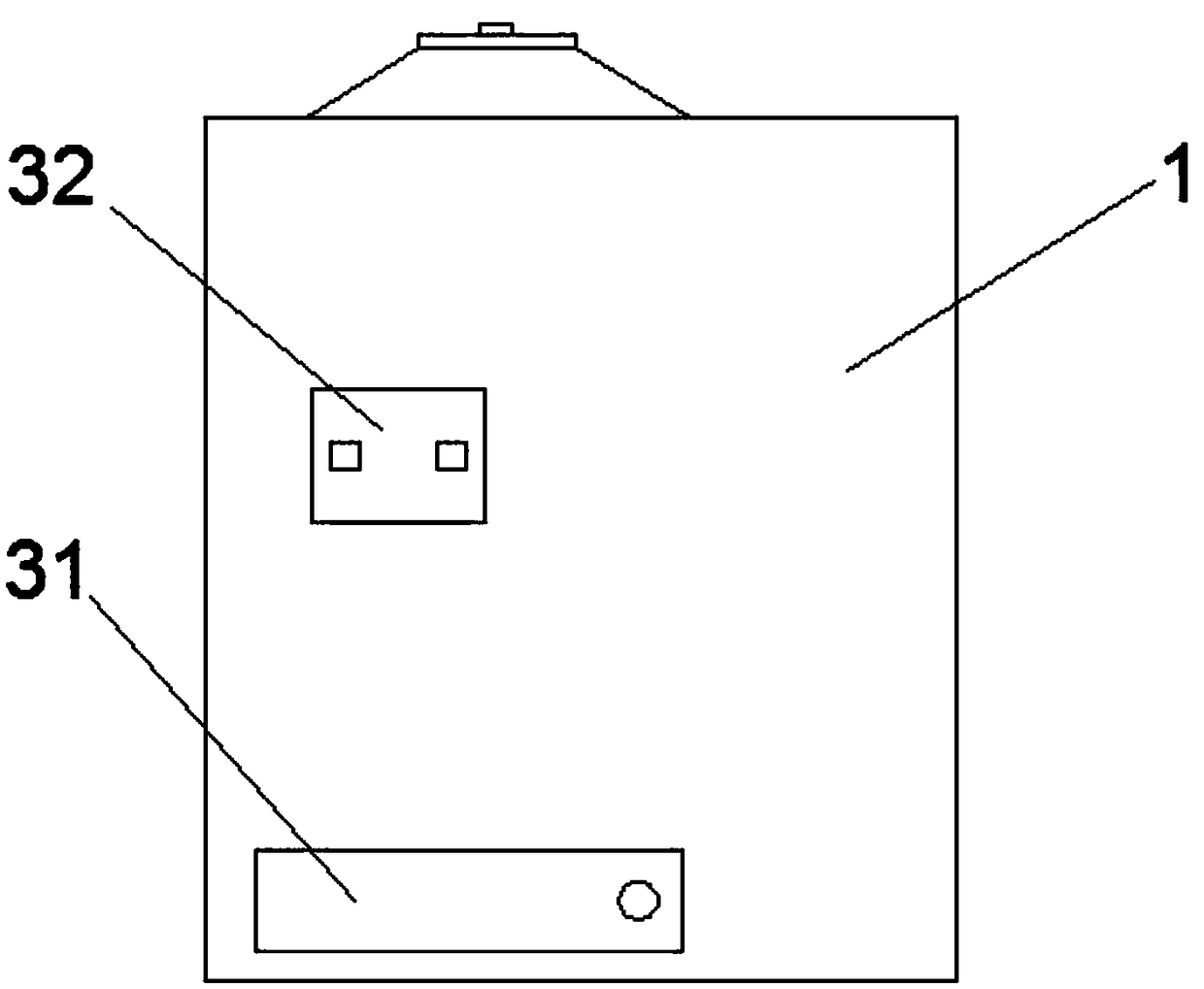

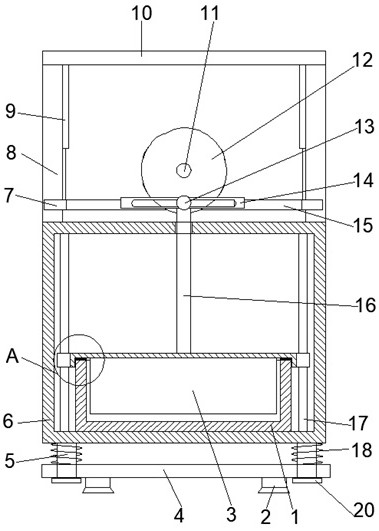

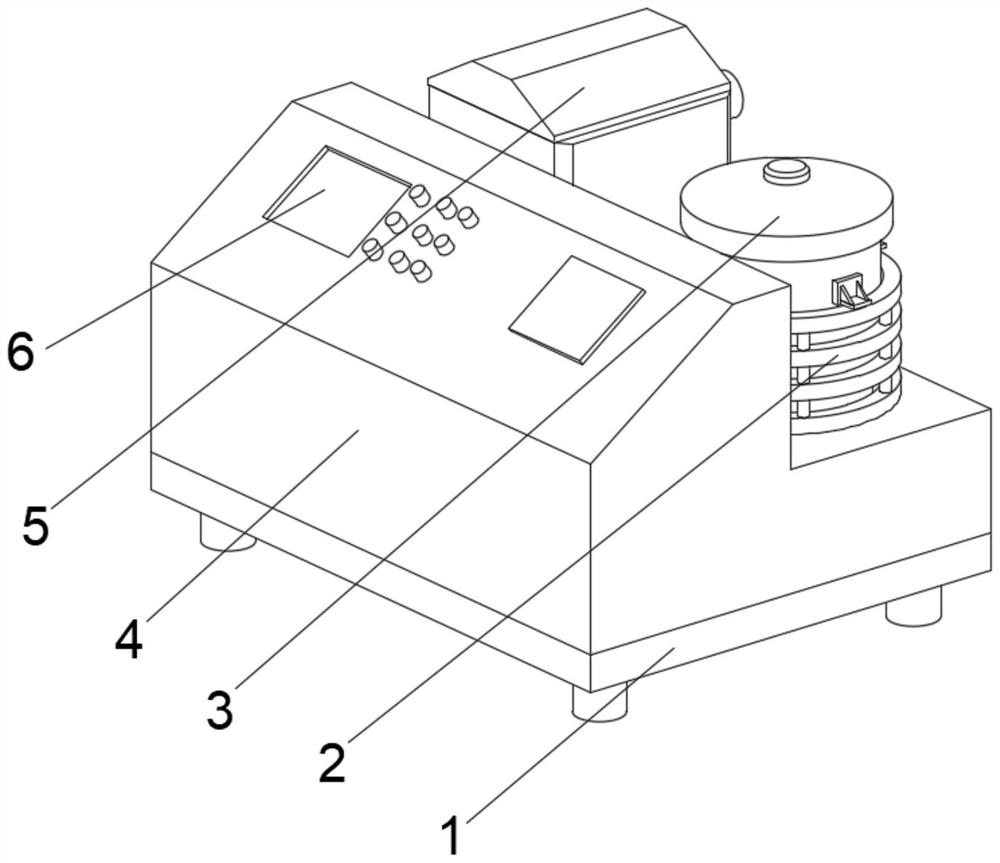

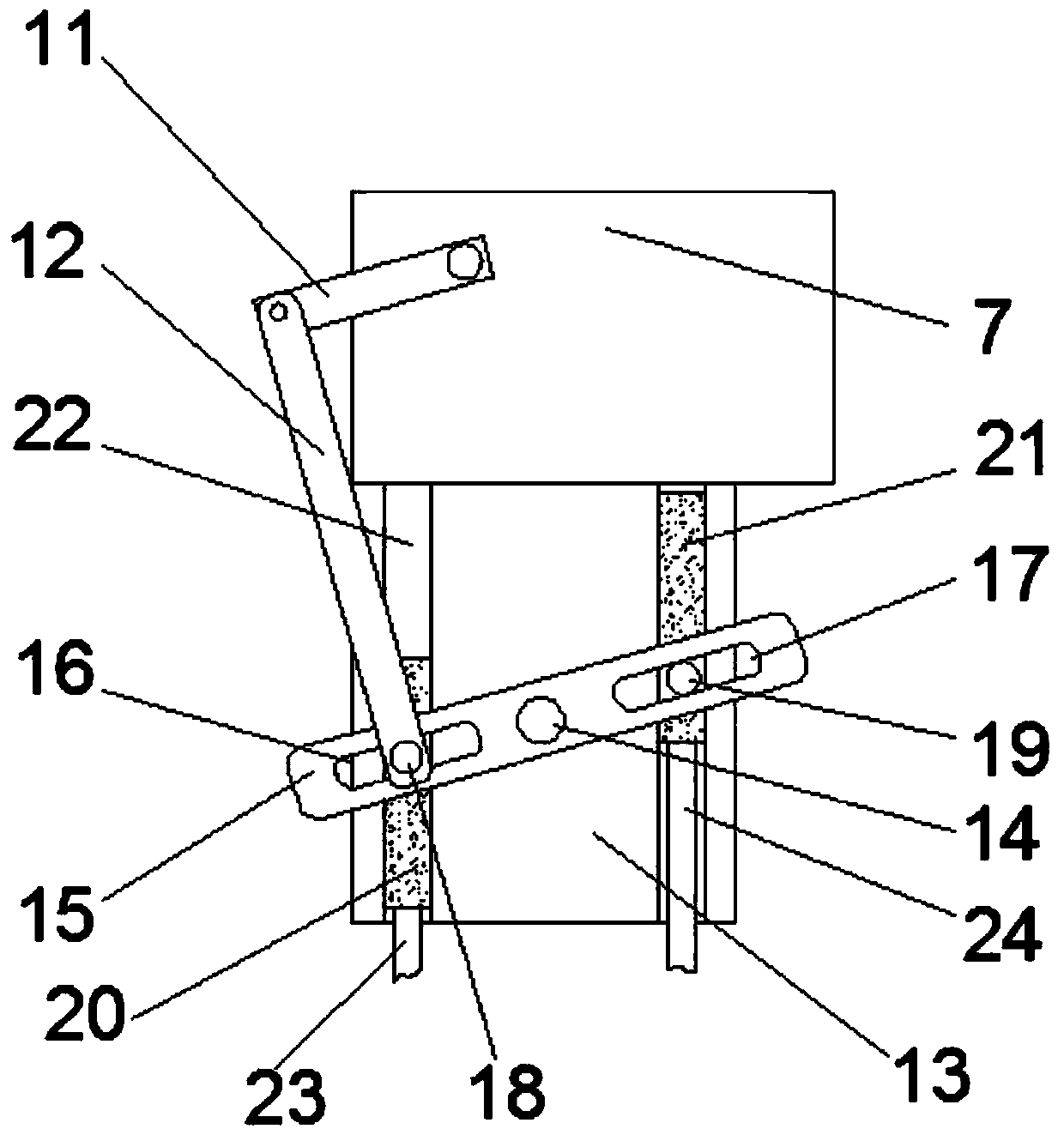

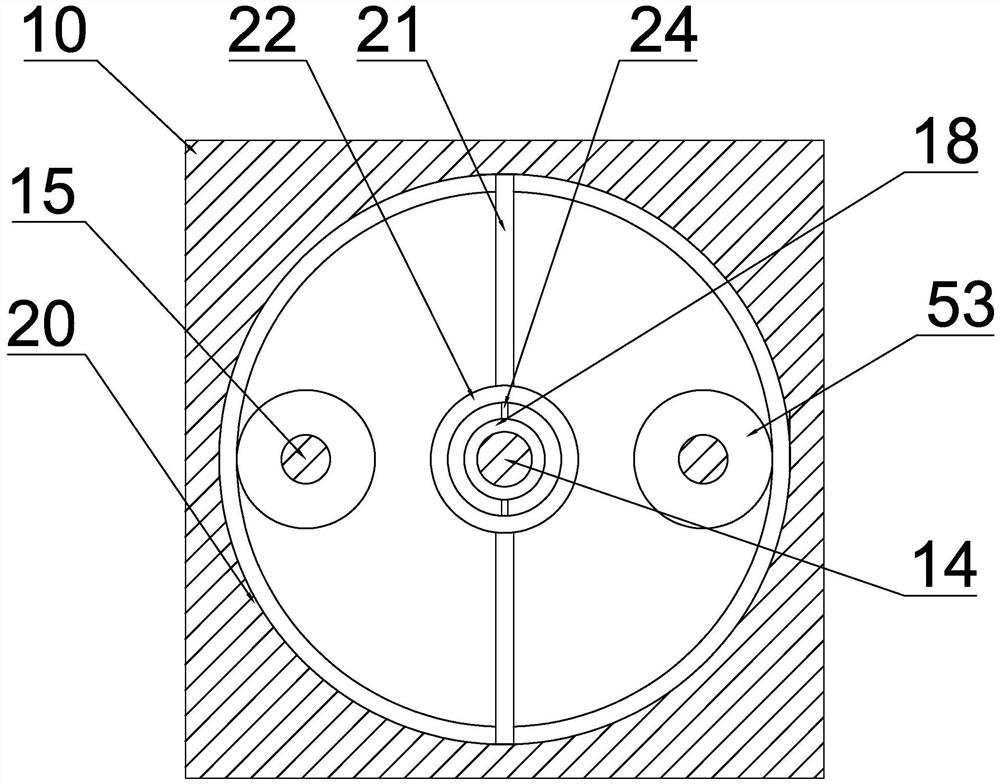

Accurate rice grinding device for rice noodle processing

ActiveCN109126966AAvoid insufficient grindingImprove grinding efficiencyGrain treatmentsElectric machineryMotor shaft

The invention discloses an accurate rice grinding device for rice noodle processing. The accurate rice grinding device for rice noodle processing comprises a box body, a storage box is arranged at theleft side of the bottom end inside the box body, a filter net is arranged inside the storage box, a fixing block is arranged in the middle of the right side inside the box body, a grinding box is arranged at the left end of the fixing block, a discharging pipe is arranged at the lower end of the grinding box, a fixing frame is arranged at the upper portion of the right side inside the box body, amotor rack is arranged at the left portion of the rear side of the fixing frame, a motor is arranged at the upper end of the motor rack, and a motor shaft is arranged at the front end of the motor. When the device works, a box cover is opened, steel teeth on a rotating gear preliminarily process rice, and the phenomenon that grinding is not sufficient during follow-up processing is avoided. An adjusting plate swings around a rotating shaft, a first thin rod and a second thin rod drive grinding plates to reciprocate, arc protrusions on the grinding plates sufficiently grind rice, and the grinding efficiency can be improved due to reciprocating motion of the two grinding plates.

Owner:安徽省富邦天成食品有限公司

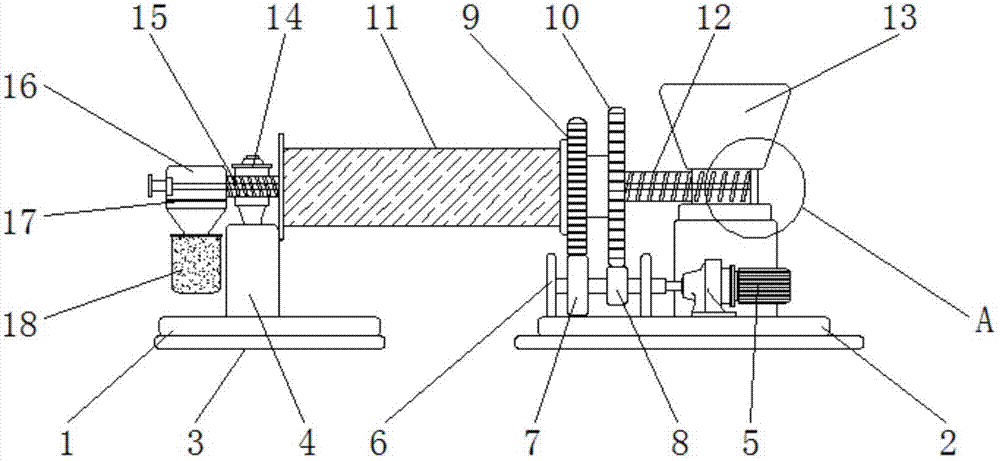

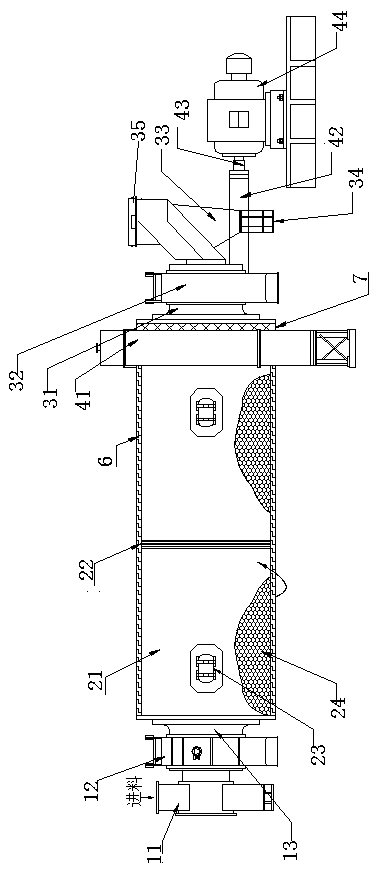

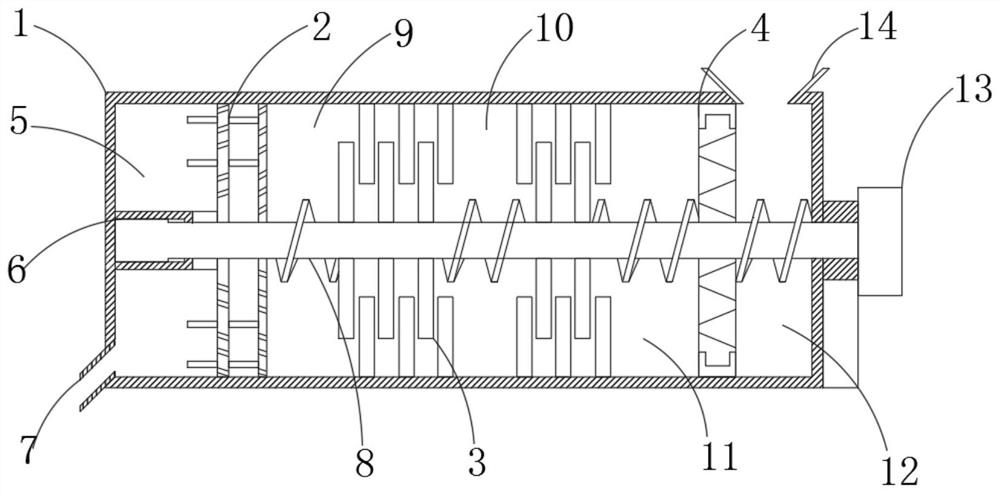

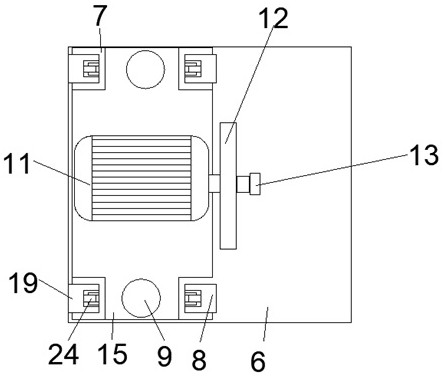

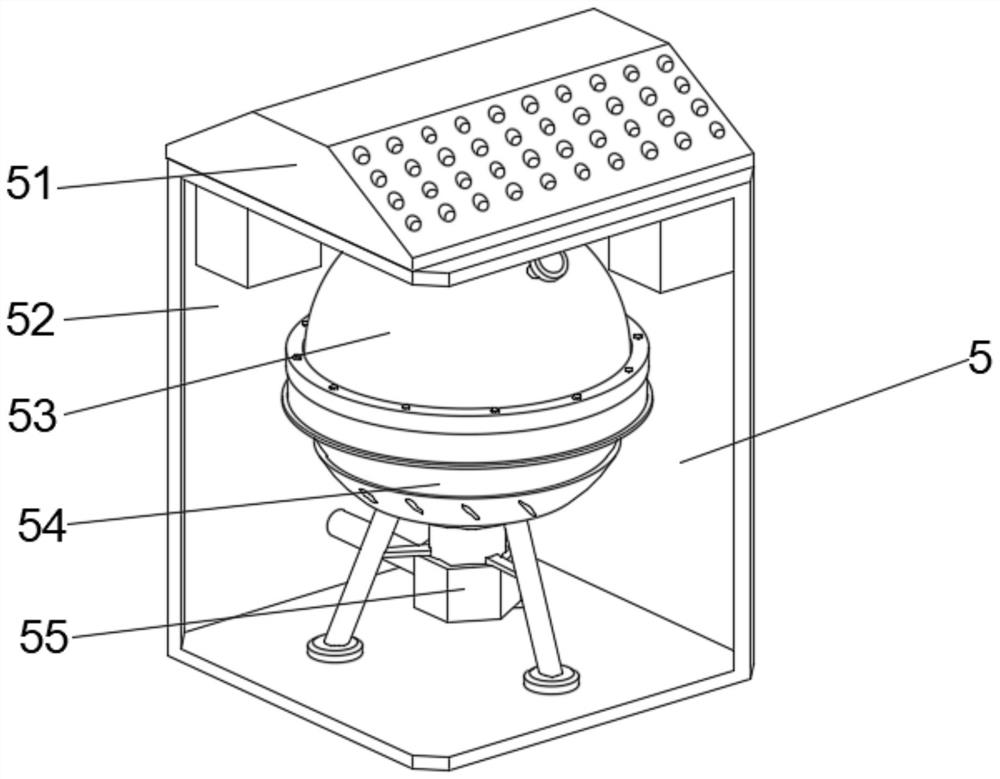

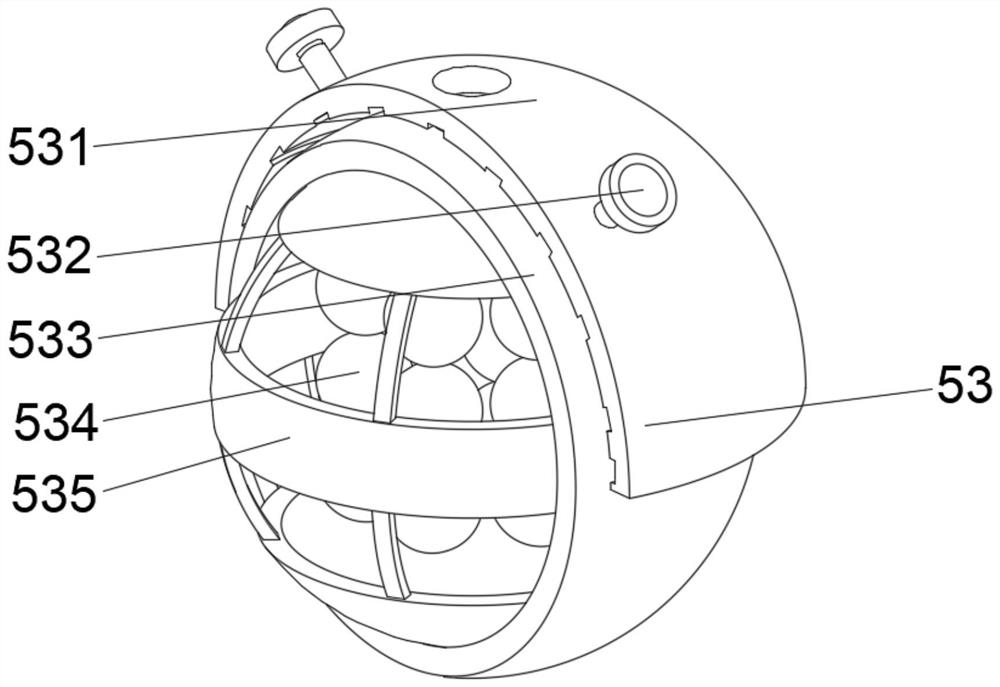

Ball mill provided with filter screen

InactiveCN109174331AExtended service lifeImprove crushing effectElectrostatic separationGrain treatmentsDrive shaftEngineering

The invention relates to a ball mill provided with a filter screen. The ball mill is characterized by comprising a feeding assembly, a grinding assembly, a discharging assembly, a power assembly and asmoke dust filtering assembly, the feeding assembly and the discharging assembly are both connected with the grinding assembly, and are arranged at the two ends of the grinding assembly correspondingly, the power assembly is installed on the right side of the discharging assembly, and is connected with the grinding assembly through a transmission shaft in the power assembly, the smoke dust filtering assembly is arranged above the discharging assembly, and is tightly connected with a filtering net belonging to the discharging assembly. According to the ball mill, the design structure is simpleand clear, all the assemblies are closely connected and do not influence each other, required parts are convenient to replace, and repair and maintenance of products in the use process in the futureis facilitated.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

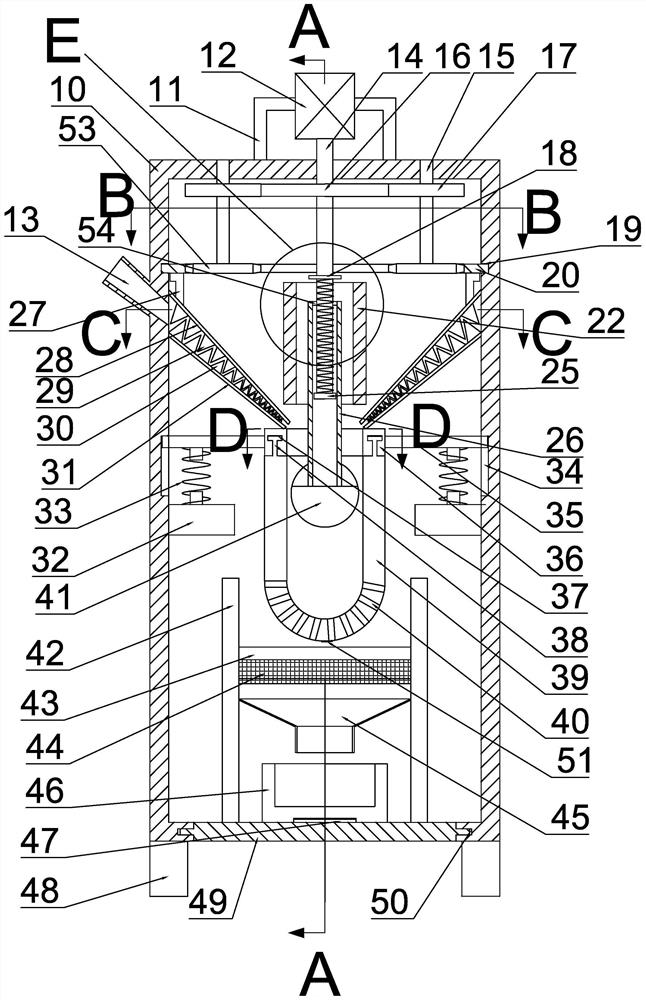

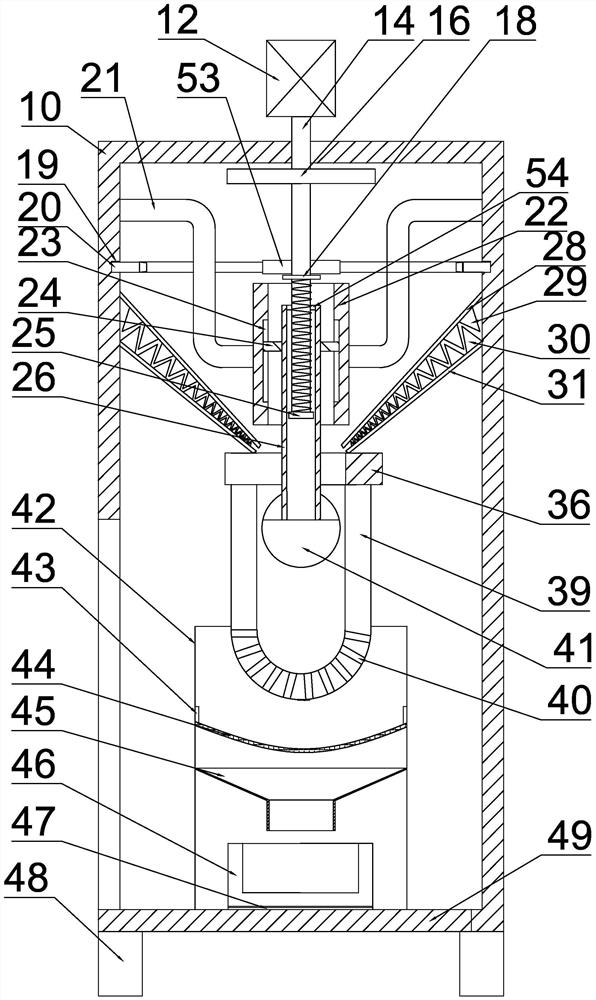

Processing device for biological reagent development

InactiveCN111940102AAvoid Insufficient GrindingDirt cleaningGrain treatmentsBiotechnologyElectric machinery

The invention relates to the technical field of biological reagents, in particular to a processing device for biological reagent development. The processing device comprises a box body. A first fixingblock and a second fixing block are coaxially welded into the box body. The top end of the first fixing block makes contact with the inner top wall of the box body. First grooves in a circular truncated cone shape are coaxially and symmetrically formed in the upper end and the lower end of the first fixing block. The two first grooves communicate with each other.Second grooves in a circular truncated cone shape are coaxially and symmetrically formed in the upper end and the lower end of the second fixing block. The two second grooves communicate with each other. The radius and the height of the upper bottom face and the lower bottom face of each first groove are the same as those of the upper bottom face and the lower bottom face of each second groove. A motor is welded to the center of the outer top wall of the box body in a perpendicular manner. According to the processing device, raw materials for producing solid reagents can be differently ground twice, the raw materials for producing the solid reagents can be ground fully, and the situation that the raw materials for producing the solid reagents are not ground fully can be avoided.

Owner:深圳市永祥医药有限公司

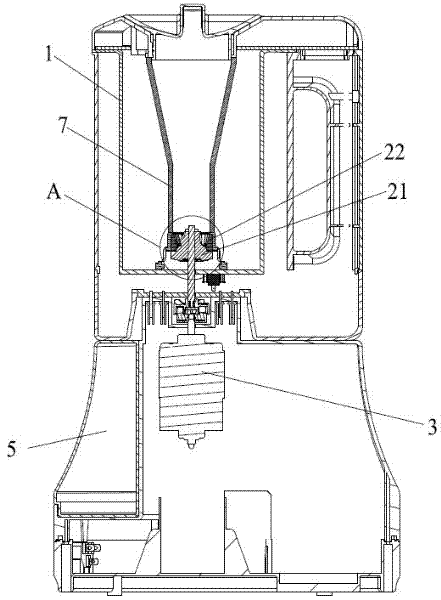

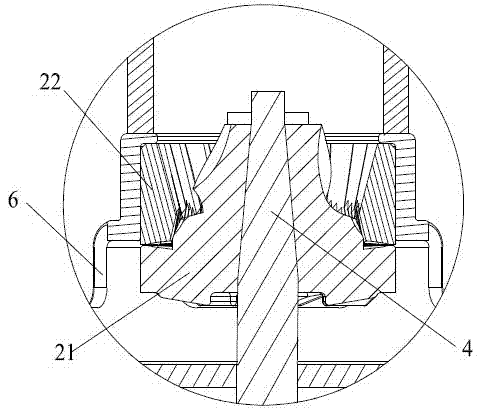

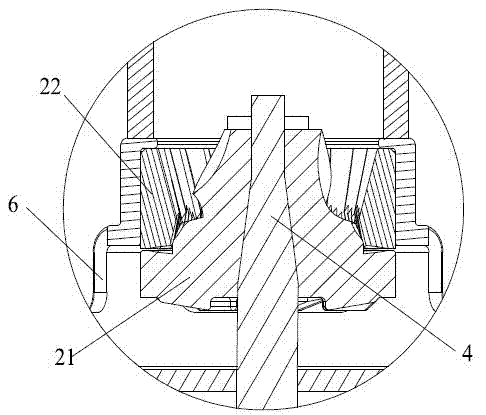

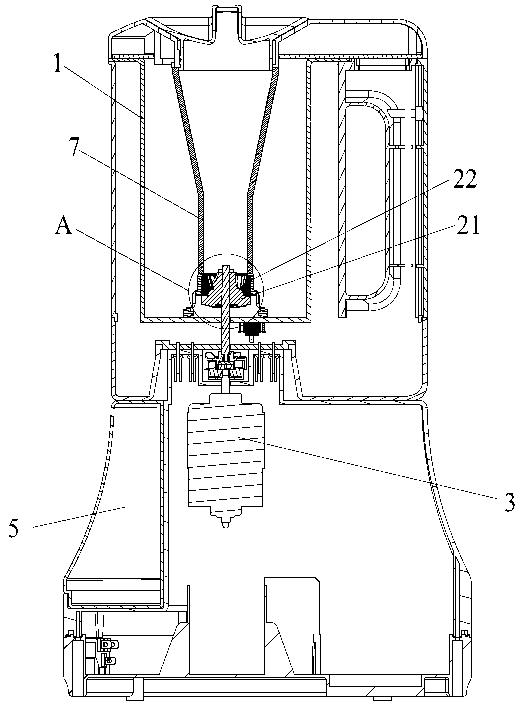

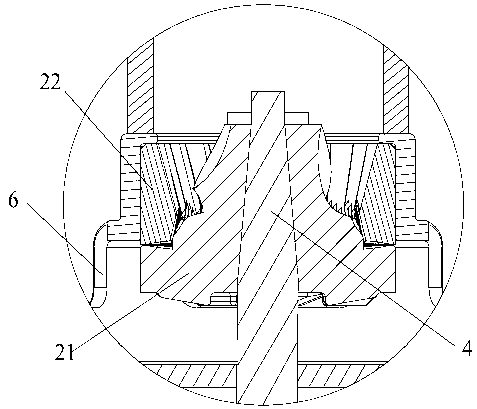

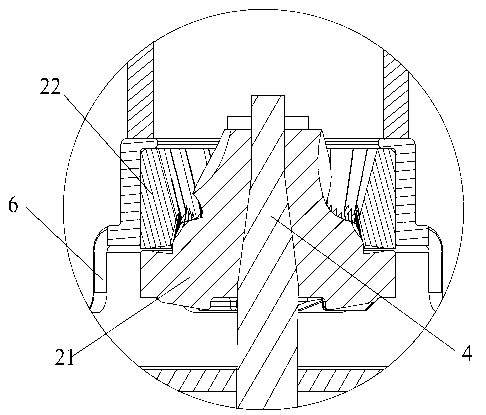

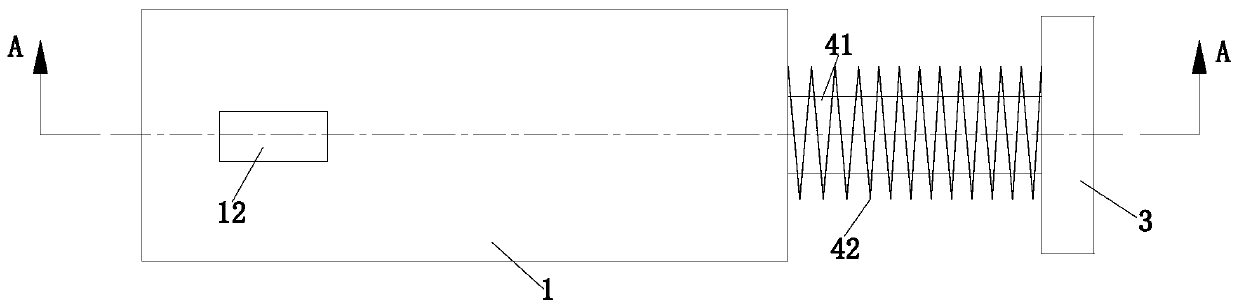

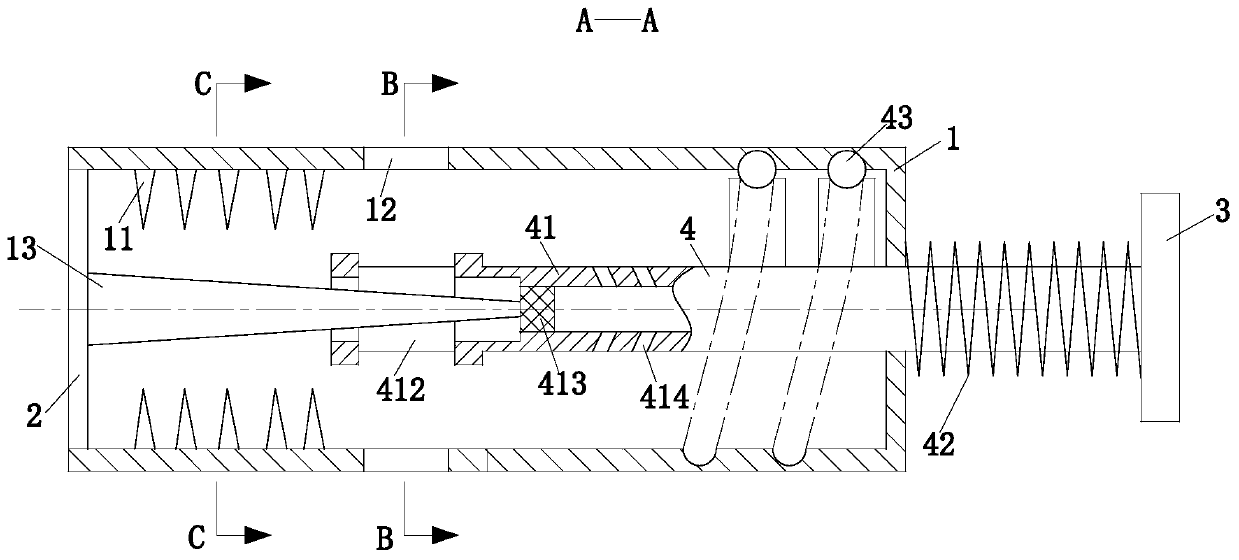

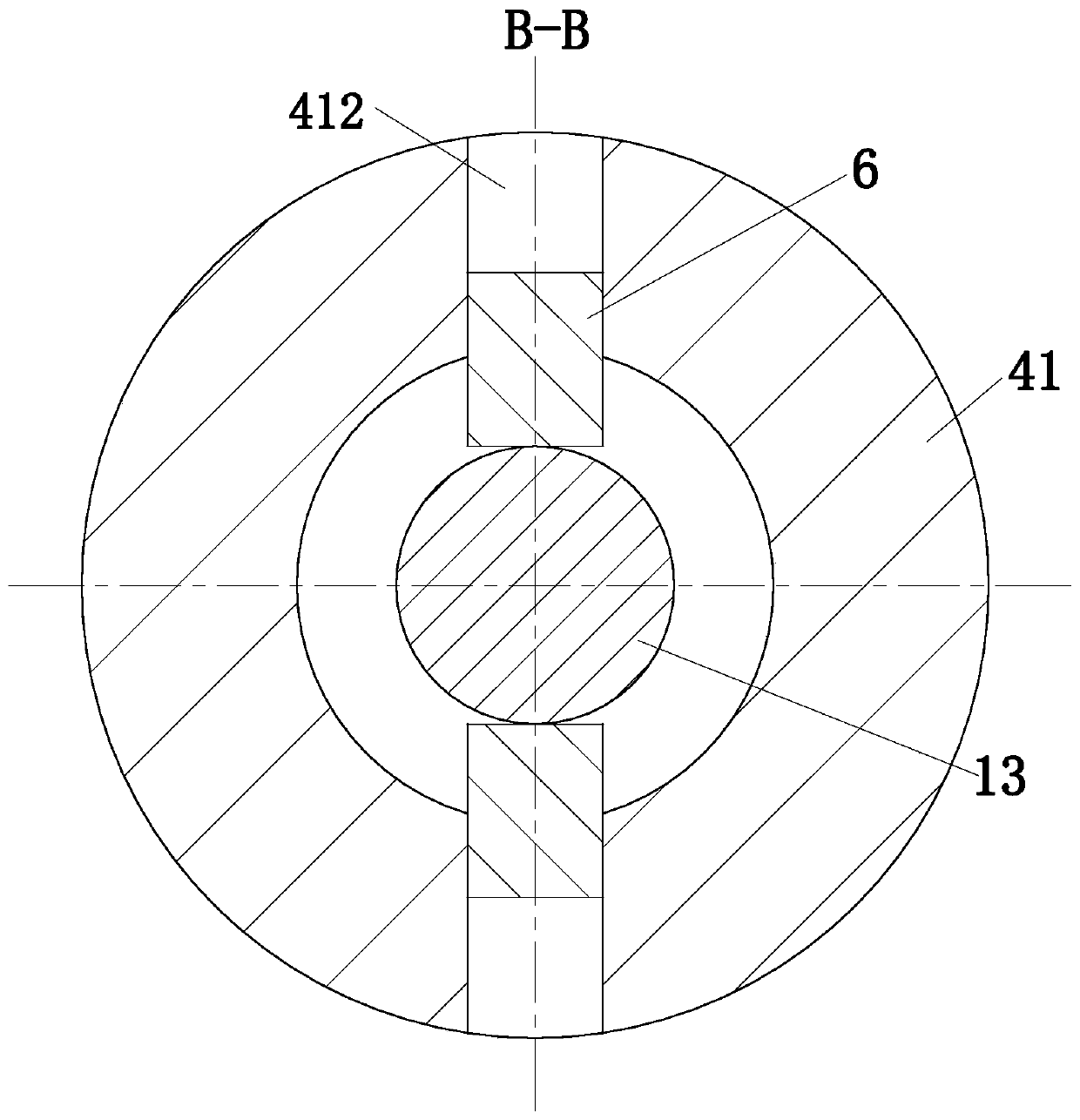

Novel grinding apparatus

The invention relates to the technical field of soybean milk makers and specifically relates to a novel grinding apparatus, comprising a motor, a movable grinding wheel and a static grinding wheel, wherein the movable grinding wheel and the static grinding wheel can rotate relatively. The movable grinding wheel is connected to the motor through a drive shaft at the center of the movable grinding wheel, a rotation gap is formed between the movable grinding wheel and the static grinding wheel, and the movable grinding wheel is connected to the drive shaft in a sliding way. At least a lower partof a connection place between the drive shaft and the movable grinding wheel is a conical post and conical hole matching structure widening from top to bottom gradually. According to the invention, by means of the special design of the conical drive shaft, the material can be prevented from getting stuck and ensured to be ground adequately.

Owner:MIDEA GRP CO LTD

Multi-stage high-speed grain grinding device

Owner:湖南创意雷家岭农业股份有限公司

feed processing equipment

InactiveCN112317030BEasy to dropGrind evenlySievingDispersed particle filtrationCouplingElectric machinery

Owner:莱阳和美华饲料有限公司

Processing device for biological reagent

InactiveCN113457812ASmooth entryAvoid Insufficient GrindingDirt cleaningGrain treatmentsBiotechnologyElectric machinery

The invention relates to the technical field of biological reagents, in particular to a processing device for a biological reagent. The device comprises a box, wherein a first fixing block and a second fixing block are coaxially welded in the box, the top end of the first fixing block is in contact with the inner top wall of the box, the upper end and the lower end of the first fixing block are coaxially and symmetrically provided with first circular-truncated-cone-shaped grooves, the two first grooves communicate with each other, the upper end and the lower end of the second fixing block are coaxially and symmetrically provided with second circular-truncated-cone-shaped grooves, and the two second grooves communicate with each other; the radius and the height of the upper bottom face and the lower bottom face of the first groove are the same as those of the upper bottom face and the lower bottom face of the second groove, and a motor is perpendicularly welded to the center of the outer top wall of the box body. According to the device, raw materials for producing a solid reagent can be ground differently twice, so that the raw materials for producing the solid reagent can be ground more sufficiently, and a situation that the raw materials for producing the solid reagent are not ground sufficiently can be avoided.

Owner:沈涛

A kind of preparation method of powder medicament for pharmacy department

ActiveCN108578241BImprove grinding efficiencyAvoid insufficient grindingOral administration devicePharmacyEngineering

Owner:淮北悯农生物科技有限公司

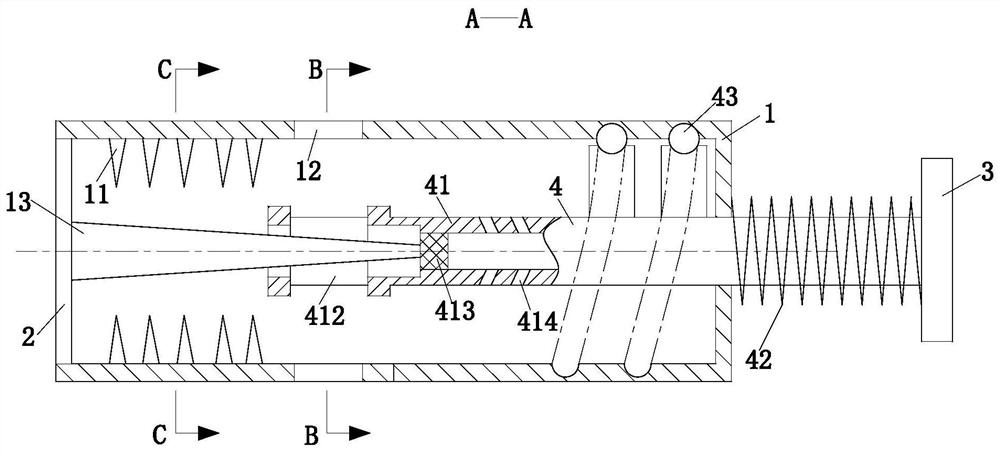

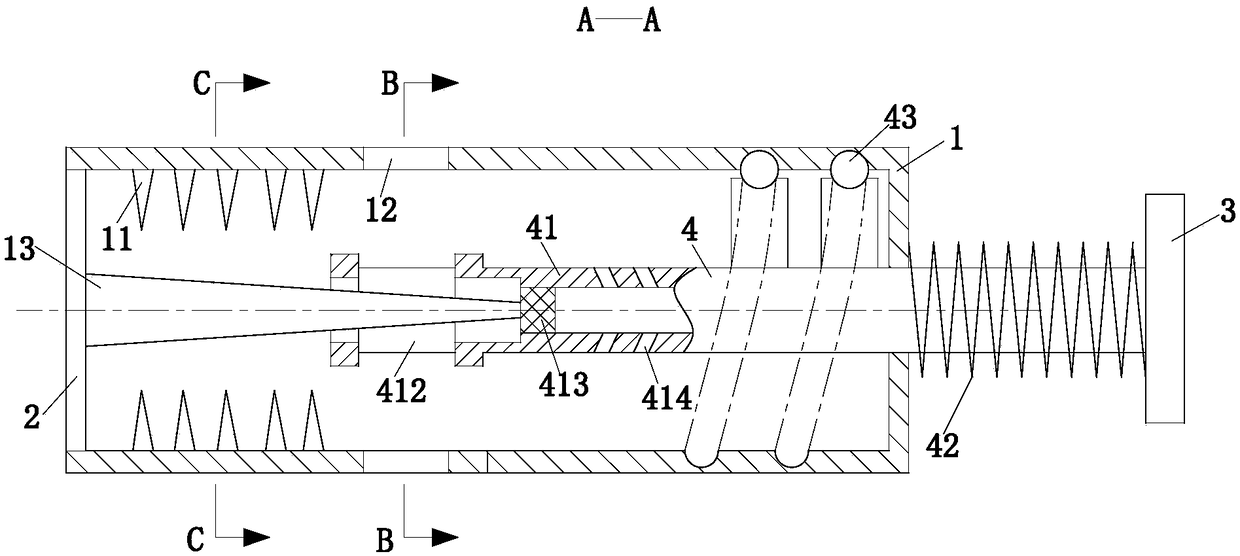

Printing ink sand mill grinding cylinder and grinding method

The invention discloses a printing ink sand mill grinding cylinder and a grinding method. The printing ink sand mill grinding cylinder comprises a grinding cylinder body, a discharging opening is formed in the lower end of the grinding cylinder body, a discharging cavity is formed in the inner side of the grinding cylinder body, a rotating shaft positioning groove is fixedly connected to one side of the discharging cavity, a rotating shaft is fixedly connected to the inner side of the rotating shaft positioning groove, and the outer side of the rotating shaft is fixedly connected with a sediment stirring mechanism. According to the printing ink sand mill grinding cylinder and the grinding method, by additionally arranging the sediment stirring mechanism, finished printing ink sand can be conveniently stirred to be dispersed and continuously conveyed to the outer side in a rotating mode, materials are prevented from blocking a discharging port, by additionally arranging a grinding wheel disc mechanism, the printing ink sand can be fully ground, the ink sand is scattered towards the outer side of a grinding wheel to be fully ground with an auxiliary grinding wheel, insufficient grinding is prevented, a backflow-preventing material conveying disc is additionally arranged, materials can be conveniently conveyed inwards, and the backflow phenomenon of the materials is effectively prevented.

Owner:SUZHOU ZHONGYA INK

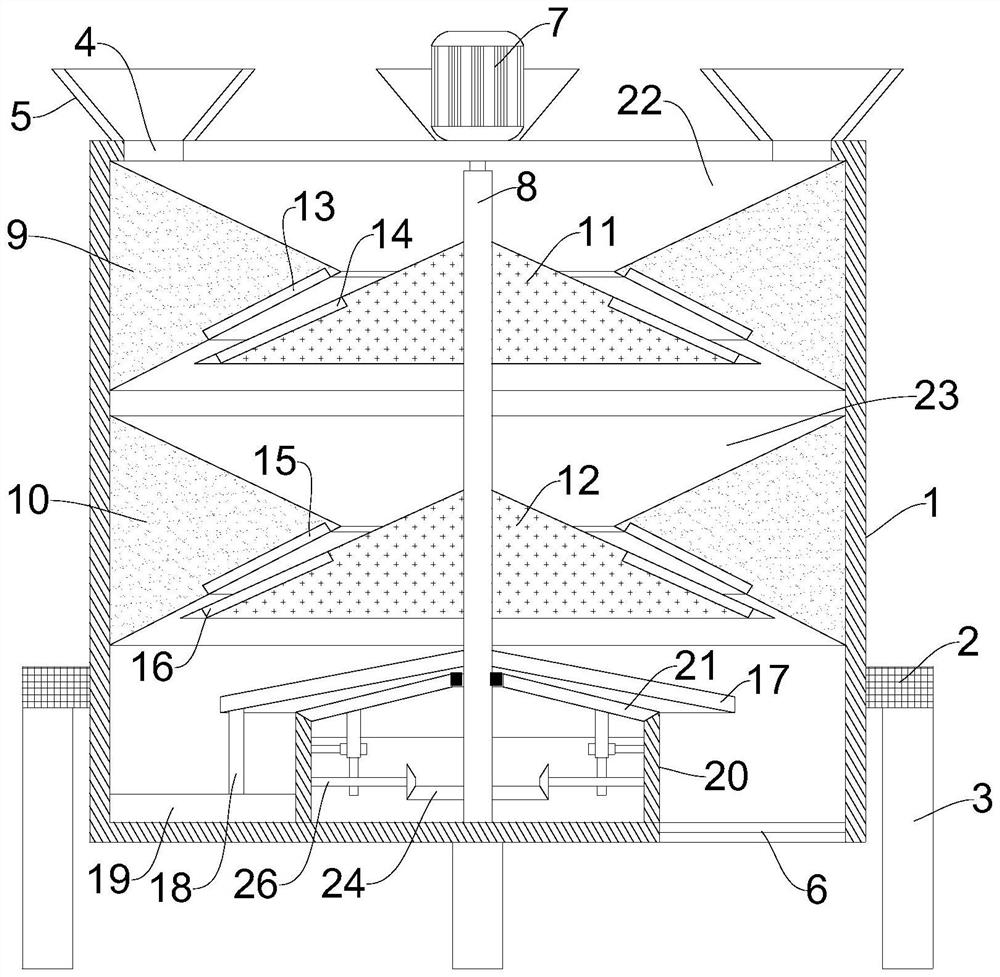

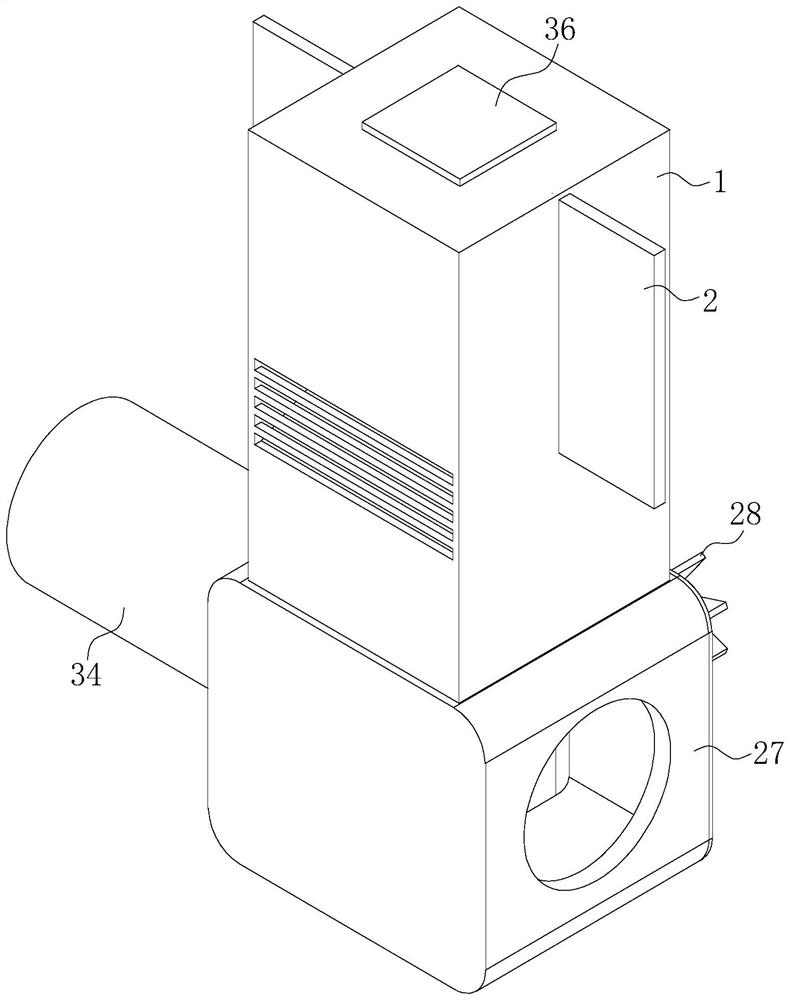

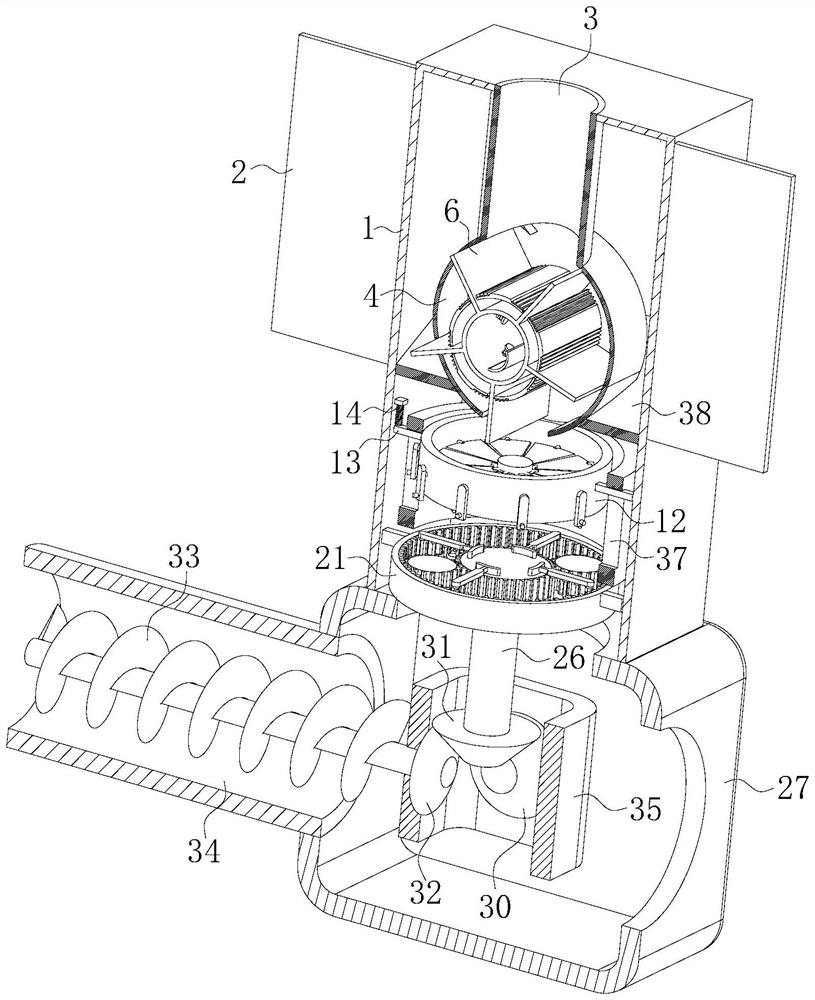

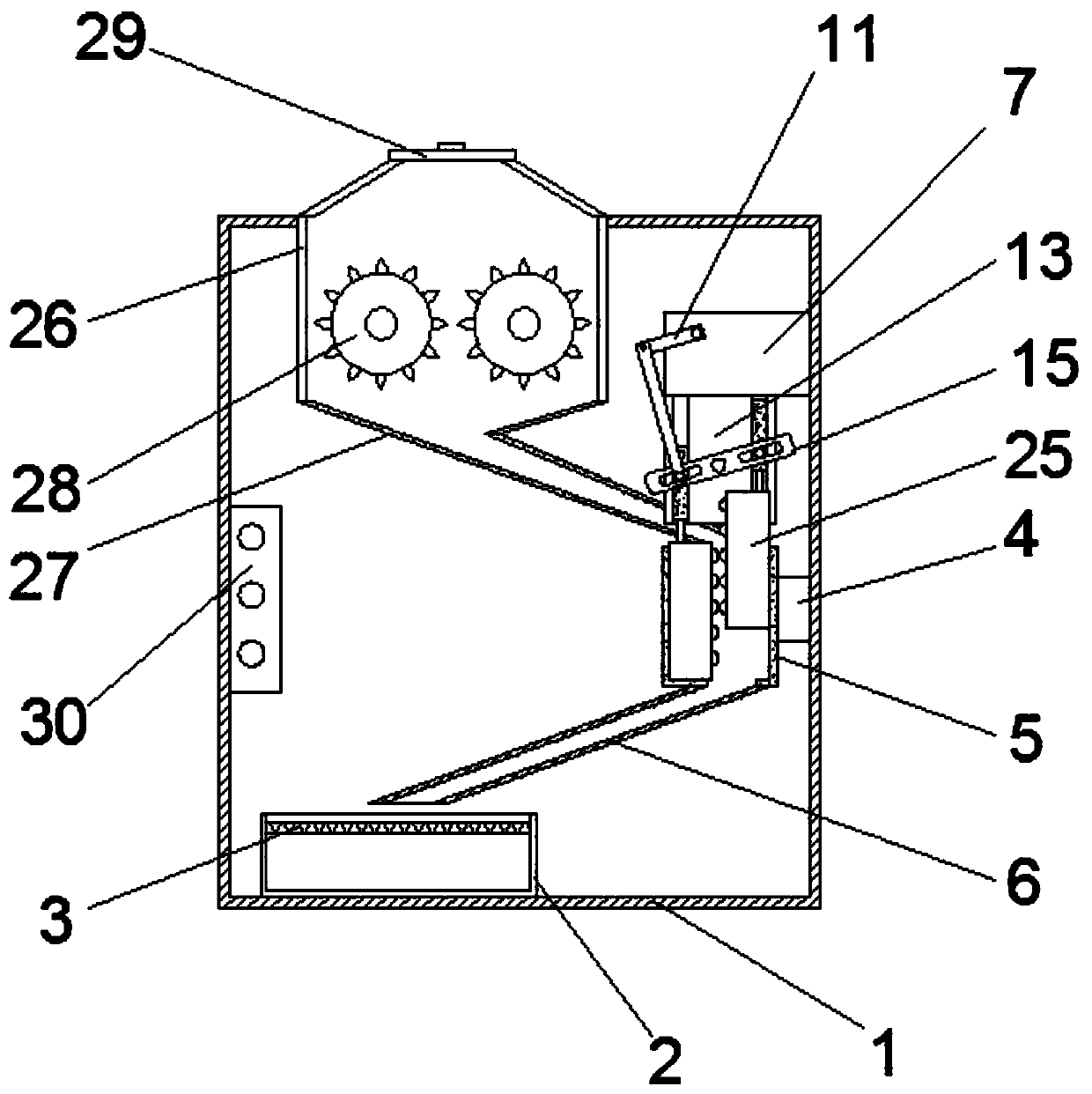

Efficient grain grinding and drying device

InactiveCN113426520AAvoid insufficient grindingIncrease flexibilityGrain treatmentsElectric machineryEngineering

The invention discloses an efficient grain grinding and drying device which structurally comprises a main box body. The main box body is provided with track plates, a grinding box body, a vibration motor, an air heater, a feeding port, a metal fixing plate, a metal baffle and a door plate, the track plates are fixedly connected to the upper end of the main box body and are arranged at the left side and the right side of the grinding box body symmetrically, the grinding box body is fixedly connected to the middle of the upper end of the main box body, the vibration motor is fixedly connected to the right end of the main box body, the air heater is fixedly connected to the left end of the main box body, and the feeding port is located in the middle of the upper end of the main box body. According to the efficient grain grinding and drying device, the distance between two grinding rollers can be effectively and automatically adjusted according to the sizes of grain particles, the phenomenon that due to the fact that the grain particles are too large or too small, the grinding rollers conduct insufficient grinding on the grain particles is avoided, and the using flexibility of the grinding and drying device is improved.

Owner:徐州徐薯食品研究院有限公司

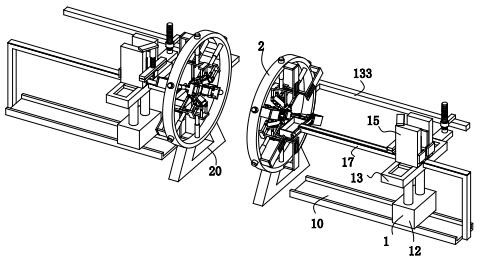

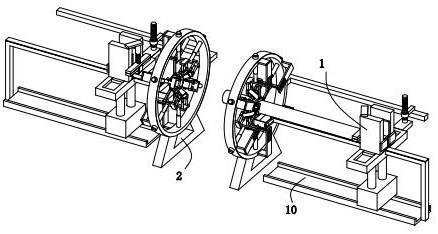

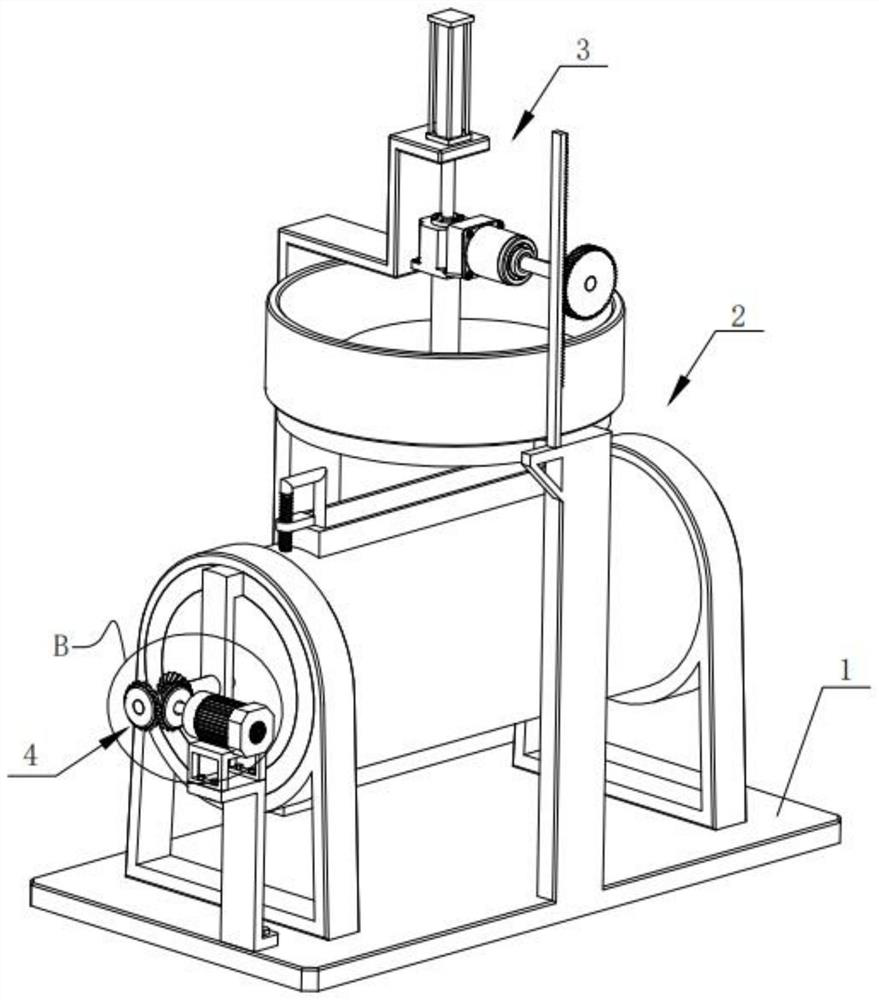

A graphite bar grinding device

ActiveCN114571302BIncrease frictionReduce the chance of driftRevolution surface grinding machinesGrinding drivesEngineeringStructural engineering

The invention relates to the field of surface treatment of graphite rods, in particular to a graphite rod grinding device, which is composed of a rod fixing unit and a grinding unit, the rod fixing unit and the grinding unit are both installed on the ground, and the The bar fixing units are arranged symmetrically on the left and right, the grinding unit is located between the bar fixing units, and the number of grinding units is two, the present invention not only performs surface grinding treatment on the graphite bar, but also can The graphite bar after surface grinding treatment is subjected to surface grinding and polishing treatment, and the surface treatment quality of the graphite bar is greatly improved through the cooperation between two different surface treatments. At the same time, in the present invention, the rod fixing unit is The clamped graphite rod is not easy to be in a suspended state, and the graphite rod has high stability and is not easy to be offset.

Owner:江苏华之沃电气智能科技有限公司

New material grinding equipment

InactiveCN112275361AAvoid insufficient grindingImprove grinding efficiencyNon-rotating vibration suppressionGrain treatmentsGrindingElectric machinery

The invention discloses new material grinding equipment. The new material grinding equipment comprises a discharge box, a support seat, a hammer block, a bottom plate, fixing rods, a box body, U-shaped plates, first support legs, hydraulic telescopic rods, a top plate, a motor, a turn table, a T-shaped rod, a sliding plate, a moving plate, a connecting rod, sliding rods, springs, second support legs, baffle plates, wearing pads, covers, sliding blocks and idler wheels, wherein small holes are formed in four corners of the edges of the bottom plate; the bottom ends of the fixing rods penetratethrough the small holes formed in the four corners of the edges of the bottom plate and are fixedly connected with the top ends of the baffle plates through bolts, and the top ends of the fixing rodsare fixedly connected with the four corners of the bottom end of the box body through bolts; and the inner bottom end of the box body is fixedly connected with the bottom end of the discharge box through bolts. The new material grinding equipment is simple in structure and convenient to use; shaking of the new material grinding equipment caused by a hammer body in the new material grinding processis avoided; and meanwhile, the hydraulic telescopic rods are arranged, so that the distance between the bottom end of the hammer body and the inner bottom end of the discharge box can be adjusted, and the new material can be fully ground.

Owner:上安实业江苏有限公司

Purification method for ceramic production

InactiveCN114405613ARealize the collectionImprove processing qualityGrain treatmentsPurification methodsProcess engineering

The invention discloses a purification method for ceramic production, which comprises a fixed bottom plate, the top of the fixed bottom plate is fixedly connected with a main body, the left side of the top of the main body is fixedly connected with a control panel, and the right side of the position, far away from the fixed bottom plate, of the main body is provided with a sintering device; and connecting frames are fixedly connected to the middles of the outer walls of the two sides of the sintering device, and a purifying device is fixedly connected to the left side of the position, away from the fixed bottom plate, of the main body. According to the purification method for ceramic production, follow-up processing work is facilitated, the processing time can be shortened, the working process in the device is in a sealed state, and the internal movement range is limited, so that the situation of dust raising during work is avoided, produced powder is fully collected, and the production efficiency is improved. And meanwhile, after high-temperature calcination, the structure of the raw material is destroyed, so that the raw material loses magnetism, full utilization of the raw material is facilitated, and the processing quality of the powder is improved.

Owner:李少航

Novel grinding apparatus

Owner:MIDEA GRP CO LTD

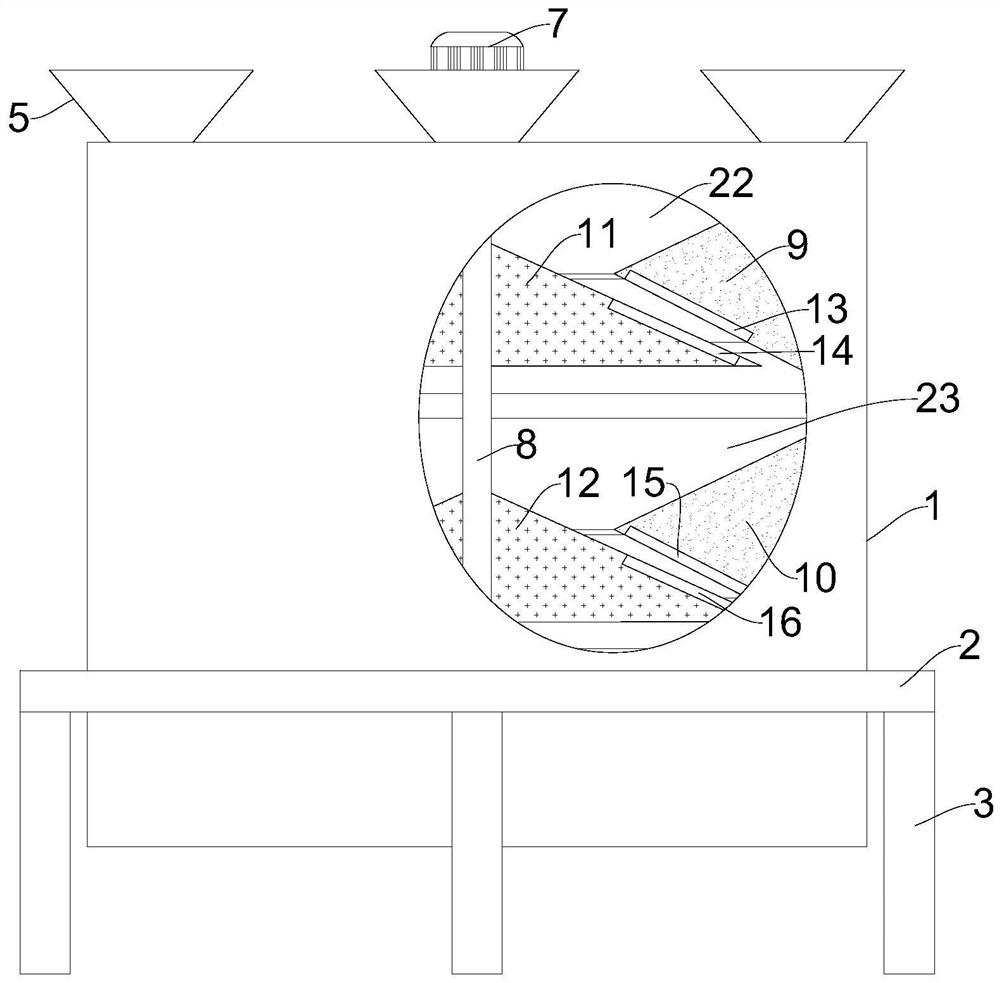

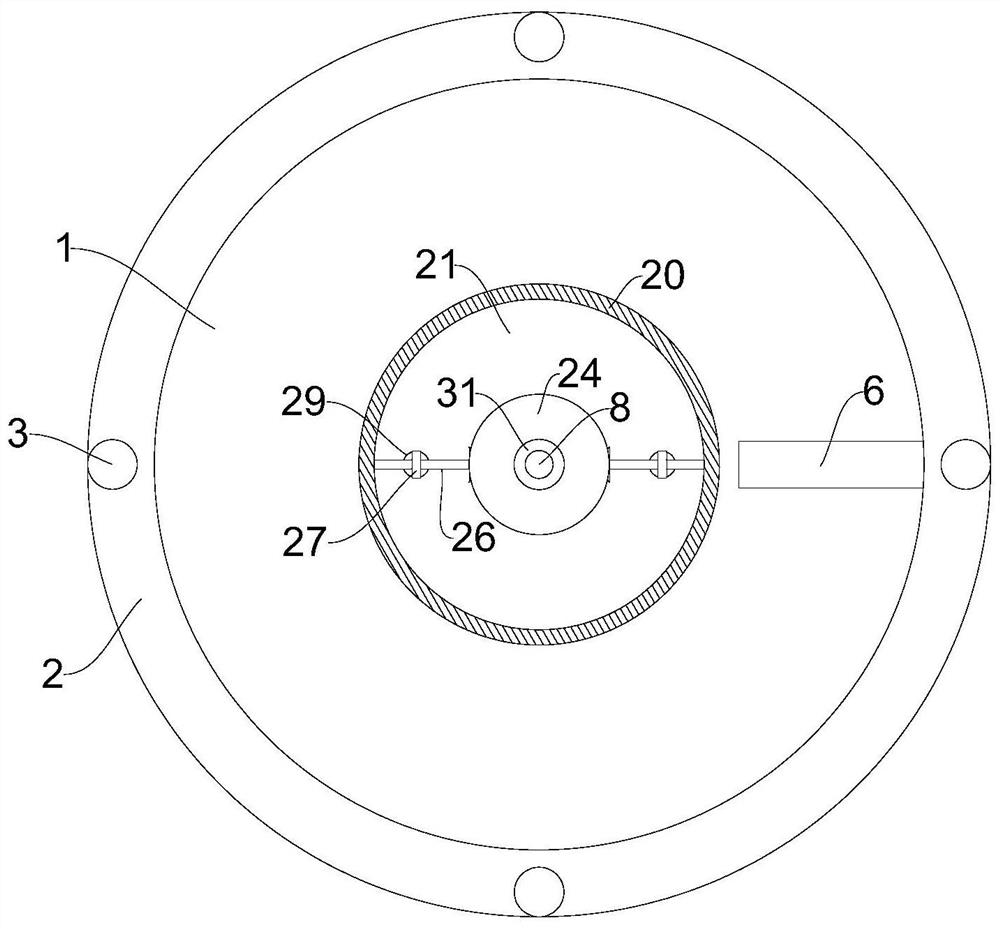

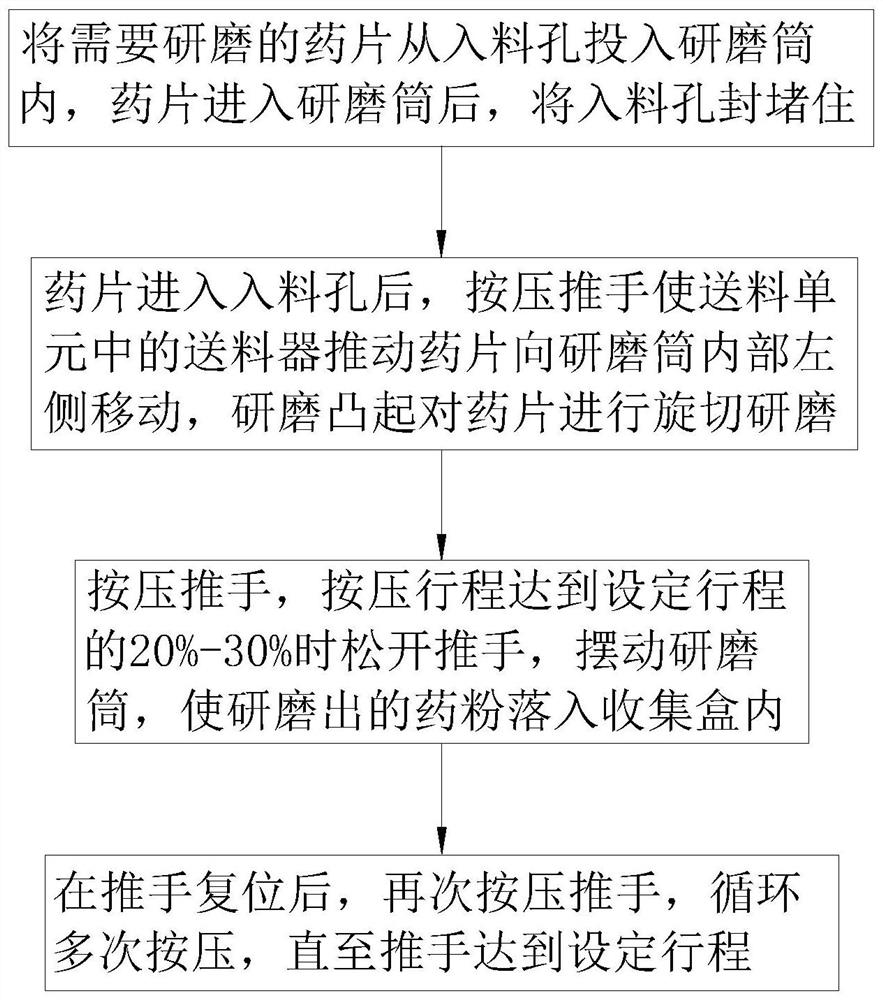

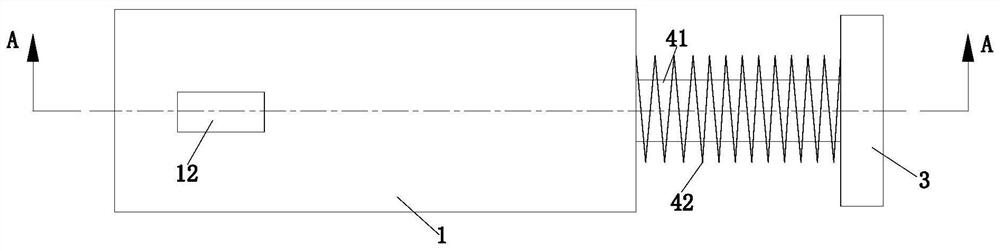

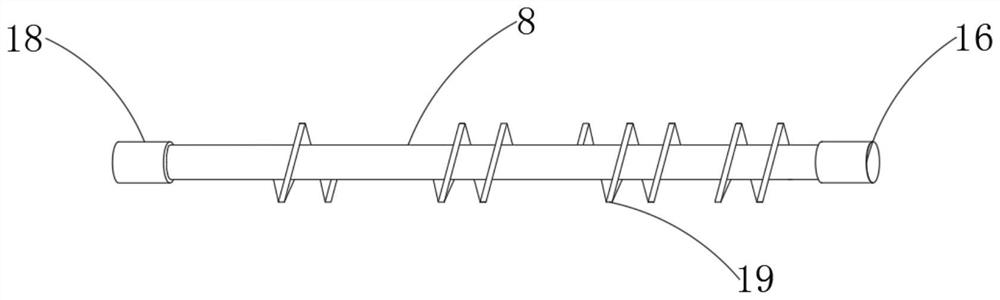

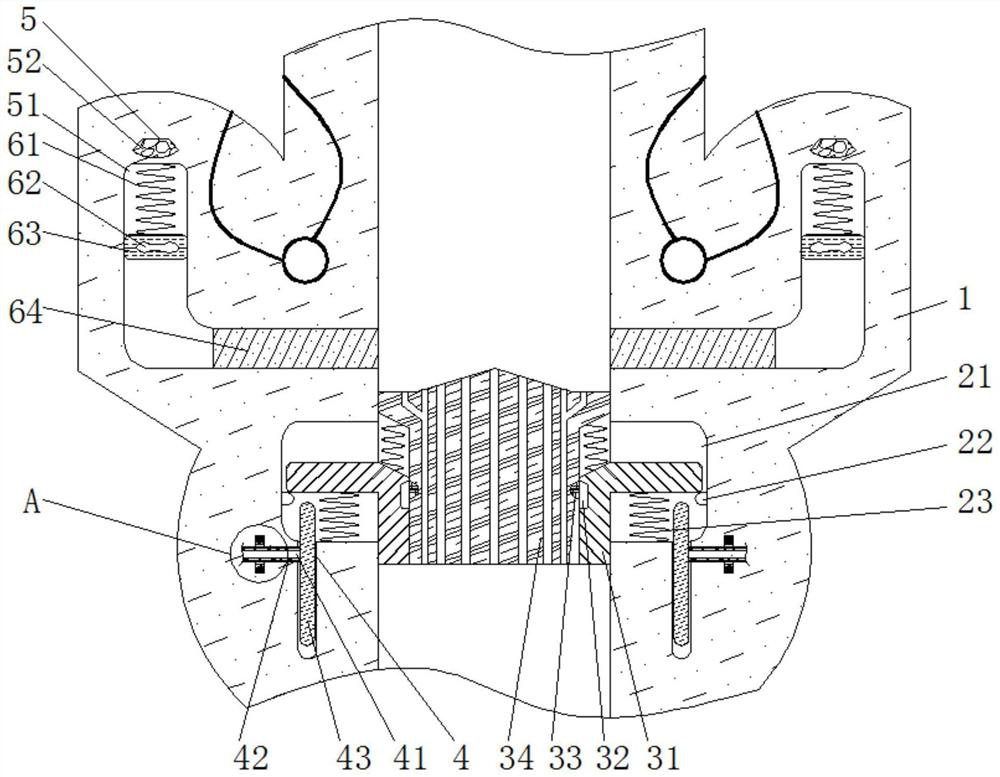

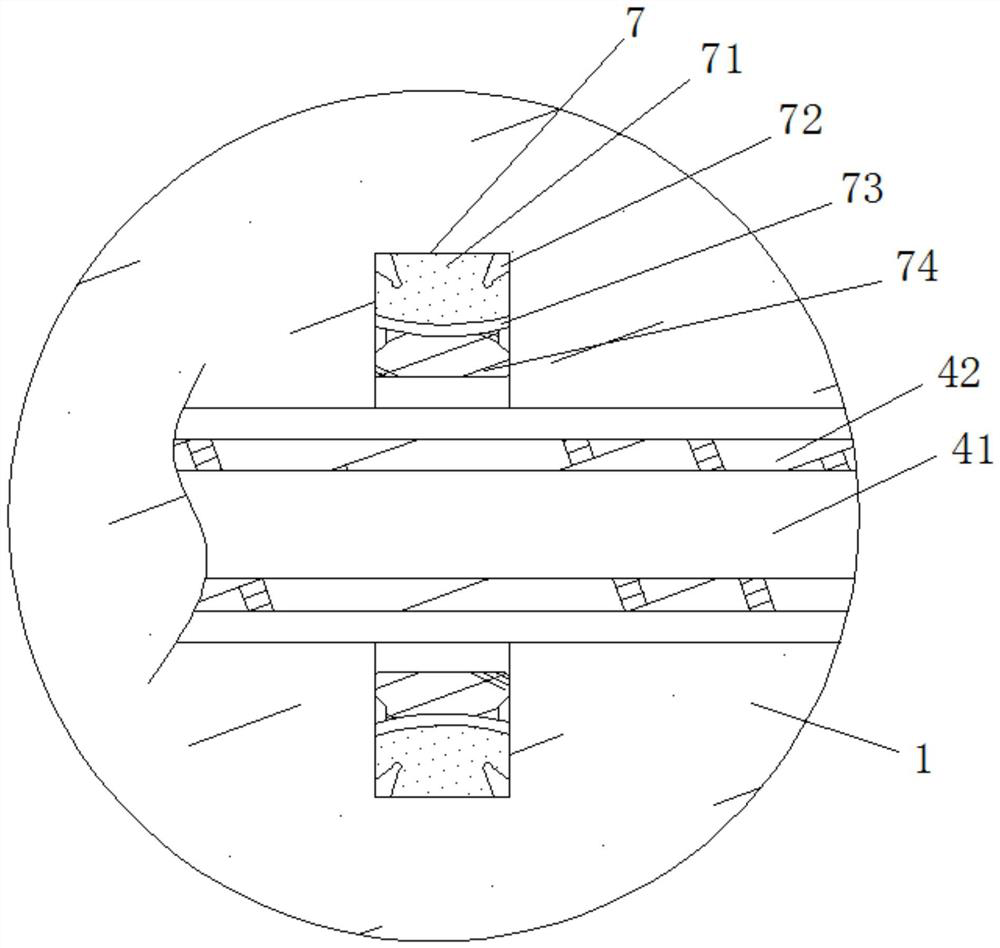

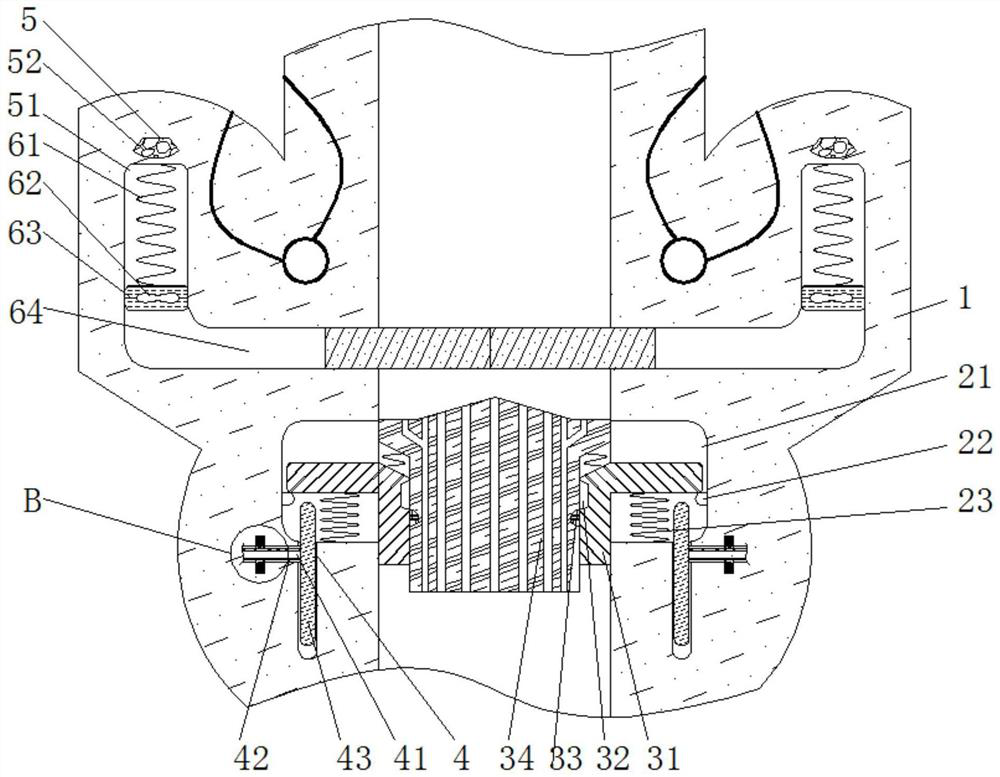

A drug crushing device for pharmacy department

ActiveCN108579970BAvoid insufficient grindingImprove grinding efficiencyOral administration deviceCleaning using toolsPharmacyNursing care

The invention belongs to the technical field of medical nursing equipment. Specifically, it is a pharmaceutical grinding device, which includes a grinding barrel, a connecting frame, a pusher and a feeding unit. The grinding barrel is a cylindrical type without a cover, and the central axis of the grinding barrel is placed horizontally; The connecting frame is vertically connected to the wall of the grinding barrel. The inner wall of the grinding barrel is provided with grinding protrusions and spiral grooves. The grinding protrusions are used to squeeze and grind tablets. The wall of the grinding barrel is vertically provided with a feeding hole. The feeding hole is located in the middle of the grinding protrusion and the spiral groove. The feeding hole is used to add tablet raw materials into the grinding barrel; the pusher is set on the right side of the outside of the grinding barrel and is used to push the tablets into the grinding barrel; the feeding unit is set Inside the grinding barrel, the feeding unit is used to send the tablets to the left side of the grinding barrel for grinding. This device fully crushes the tablets entering the grinding barrel through the interaction of the grinding protrusions inside the grinding barrel and the push block. , grinding cost is low and easy to operate.

Owner:范晓素

River ecological restoration device

ActiveCN114164809AIncrease oxygen contentProtect the environmentWater cleaningSustainable biological treatmentTreatments waterEnvironmental engineering

The invention discloses a river ecology restoration device in the technical field of river ecology, a collecting mechanism comprises a mounting plate, one end of the mounting plate is fixedly mounted on the outer surface of a water inlet cylinder, a water inlet is fixedly mounted at the top end in the water inlet cylinder, and a collecting box for collecting aquatic plants is fixedly connected to the lower end of the water inlet; the interior of the collecting box is rotatably connected with a rotary drum, the outer surface of the rotary drum is fixedly connected with a plurality of baffles distributed in a circumferential array, and a material pushing plate is arranged between every two adjacent baffles, so that duckweed collected on a river can be effectively collected, and the collecting mechanism can well separate water from duckweed; the duckweed collecting device can effectively collect duckweed collected on a river, the collecting mechanism can well separate water from the duckweed, the volume of the water and the duckweed together is reduced, the volume of the water and the duckweed together in subsequent grinding and smashing treatment is facilitated, and subsequent grinding and smashing treatment is facilitated.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

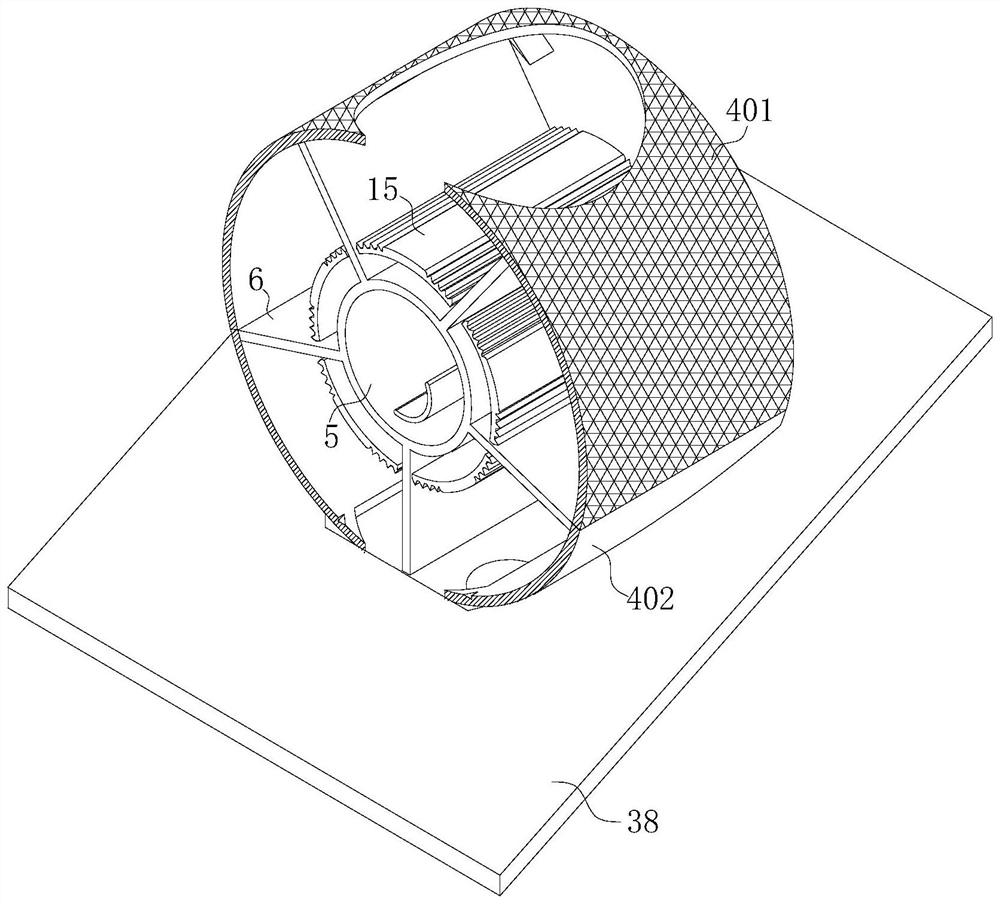

Grain grinding device capable of intermittently discharging and automatically screening

The invention relates to the technical field of grain grinding, and discloses an intermittent discharging and automatic screening grain grinding device which comprises an equipment main body, a grinding box is arranged in the equipment main body, a discharging mechanism is arranged in the grinding box, and a feeding hopper is fixedly connected to the upper end of the grinding box; a supporting plate is arranged below the grinding box, and a first motor is fixedly connected to the upper portion of the left end of the supporting plate. According to the grain grinding device capable of achieving intermittent discharging and automatic screening, after ground products fall to the upper end of the screen plate, a second motor drives a crank to rotate so as to drive a long sliding block to slide left and right in a reciprocating mode through a connecting rod, then the screen plate continuously shakes, and qualified ground products fall into a collecting box below through the screen plate; and unqualified grinding products roll into the tubular spiral conveyor and are conveyed into the feeding hopper again for secondary grinding, so that the grinding products are automatically screened and automatically recycled for secondary grinding, and the utilization rate of raw materials is increased.

Owner:邳州市华博农业发展有限公司

A small amount of metallic tissue grinding device

ActiveCN110653050BAvoid insufficient grindingFast deliveryPreparing sample for investigationGrain treatmentsPlant tissueTissue sample

Owner:FOSHAN UNIVERSITY

Rice fine grinding equipment for processing rice noodle

ActiveCN109126966BFacilitate subsequent processingAvoid insufficient grindingGrain treatmentsReciprocating motionAgricultural engineering

The invention discloses an accurate rice grinding device for rice noodle processing. The accurate rice grinding device for rice noodle processing comprises a box body, a storage box is arranged at theleft side of the bottom end inside the box body, a filter net is arranged inside the storage box, a fixing block is arranged in the middle of the right side inside the box body, a grinding box is arranged at the left end of the fixing block, a discharging pipe is arranged at the lower end of the grinding box, a fixing frame is arranged at the upper portion of the right side inside the box body, amotor rack is arranged at the left portion of the rear side of the fixing frame, a motor is arranged at the upper end of the motor rack, and a motor shaft is arranged at the front end of the motor. When the device works, a box cover is opened, steel teeth on a rotating gear preliminarily process rice, and the phenomenon that grinding is not sufficient during follow-up processing is avoided. An adjusting plate swings around a rotating shaft, a first thin rod and a second thin rod drive grinding plates to reciprocate, arc protrusions on the grinding plates sufficiently grind rice, and the grinding efficiency can be improved due to reciprocating motion of the two grinding plates.

Owner:安徽省富邦天成食品有限公司

Data processing server for food safety

PendingCN113655865AAvoid insufficient grindingAvoid pollutionDigital processing power distributionFood safetyGear wheel

The invention belongs to the field of food safety detection, and relates to a data processing server for food safety. The data processing server for food safety comprises a shell, a motor bracket is fixedly arranged on the upper side of the shell, a motor is fixedly arranged in the middle of the motor bracket, a main shaft is arranged at the output end of the motor, the main shaft penetrates through the upper side wall of the shell and extends into the inner cavity of the shell, a driving gear is fixedly arranged on the upper side of the main shaft, and transmission shafts are rotationally arranged on the left side and the right side of the upper side wall of the shell. The data processing server is a food sampling device for automatically sampling food, the food enters from a feeding port, the food is cut and preliminarily ground through continuous meshing of gradually-changed cutting teeth, the preliminarily ground food is extruded and ground, finally, a food sample obtained through collection and filtration falls into a storage box, and a worker can directly take away the food sample for safety detection.

Owner:上海春鸟网络科技有限公司

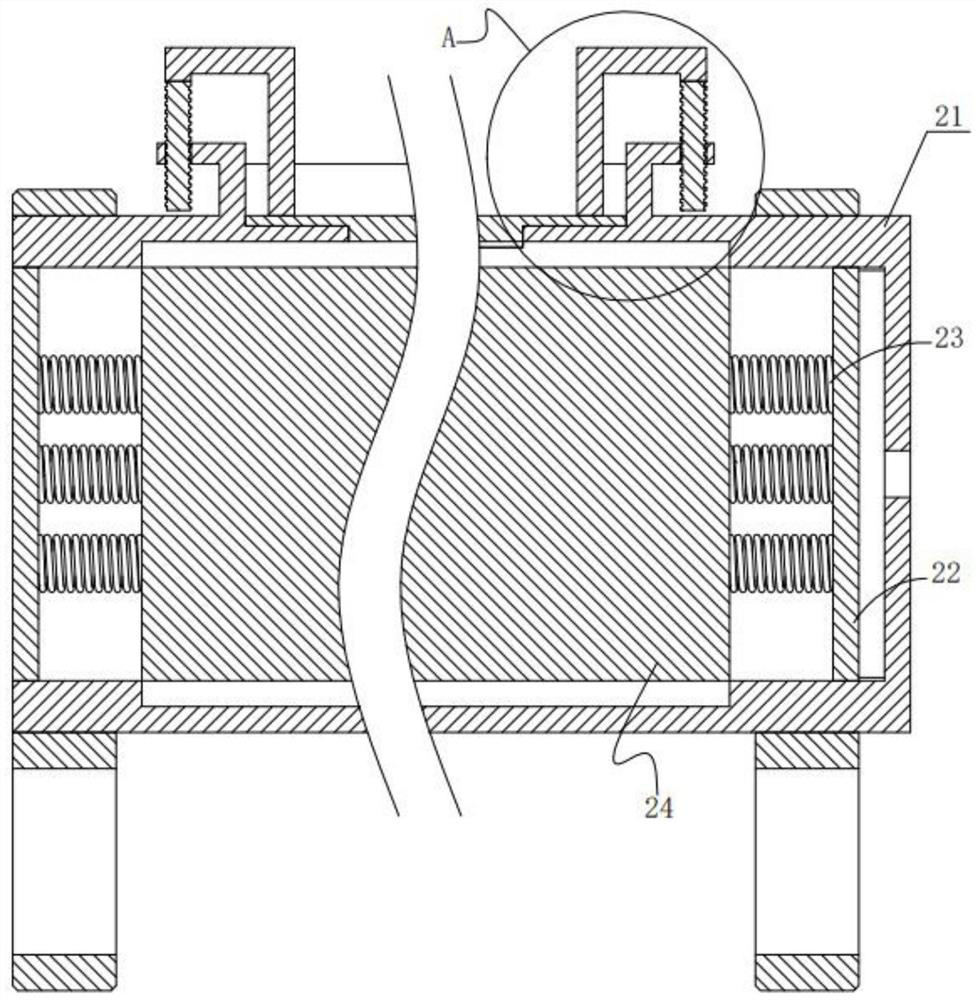

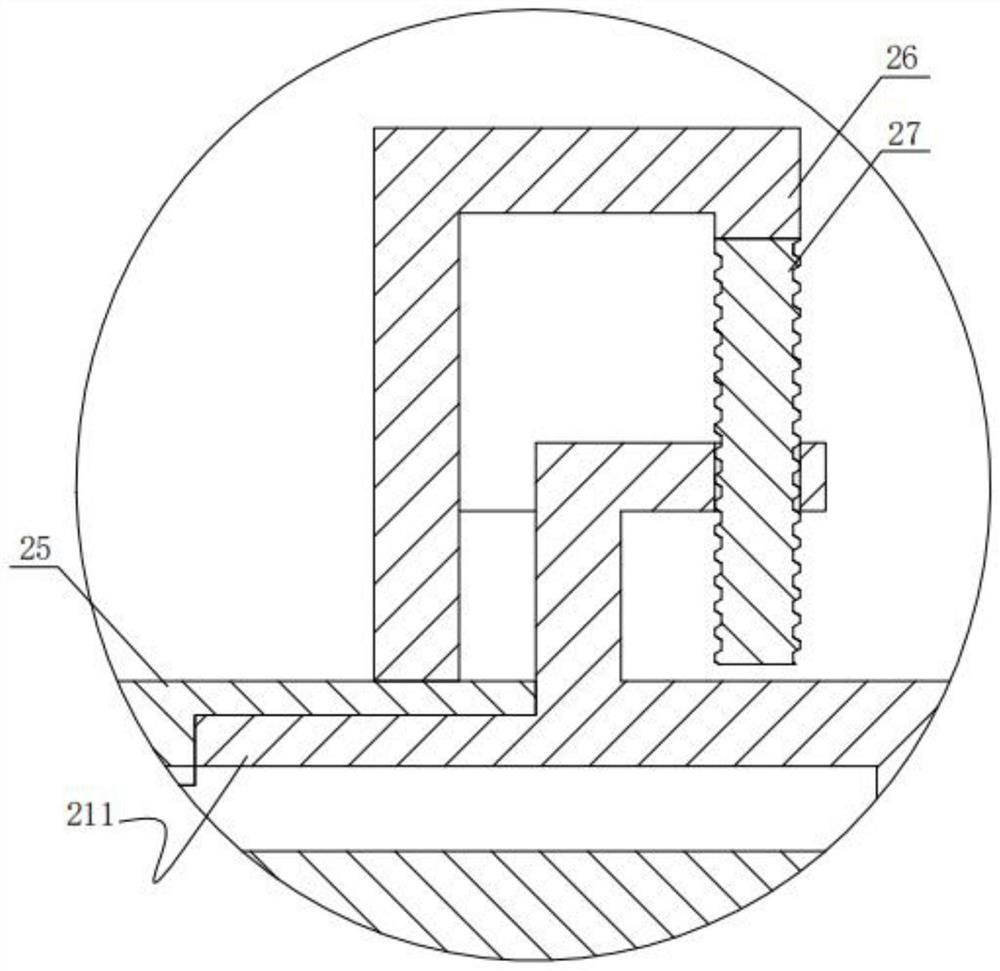

Grinding device for flour processing

InactiveCN112657607AAvoid Insufficient GrindingGuaranteed grinding effectGrain treatmentsEngineeringThreaded rod

The invention provides a grinding device for flour processing. The grinding device for flour processing comprises a bottom plate, a grinding assembly, a crushing assembly and a coaxial reverse driving assembly. The grinding assembly comprises a grinding box, side plates, springs, a grinding roller, a T-shaped cover plate, a connecting rod and a threaded rod, the grinding box is rotationally installed on the bottom plate through a supporting frame, the side plates are rotationally installed at the two ends of the grinding box, the two ends of the grinding roller are connected with the two side plates through the springs correspondingly, the coaxial reverse driving assembly is used for driving the grinding box and the grinding roller to rotate in the opposite directions, and the crushing assembly is located above the grinding assembly. The grinding box and the grinding roller are driven by the coaxial reverse driving assembly to rotate in the opposite directions, so that the grinding effect is guaranteed. The grinding box and the grinding roller can both rotate automatically, and the situation that wheat is accumulated and cannot be fully ground is avoided. The gap between the grinding roller and the grinding box is flexibly adjustable, therefore, the rotary grinding roller shakes under the interference of wheat, and the grinding effect is further improved.

Owner:安徽德鑫源食品有限公司

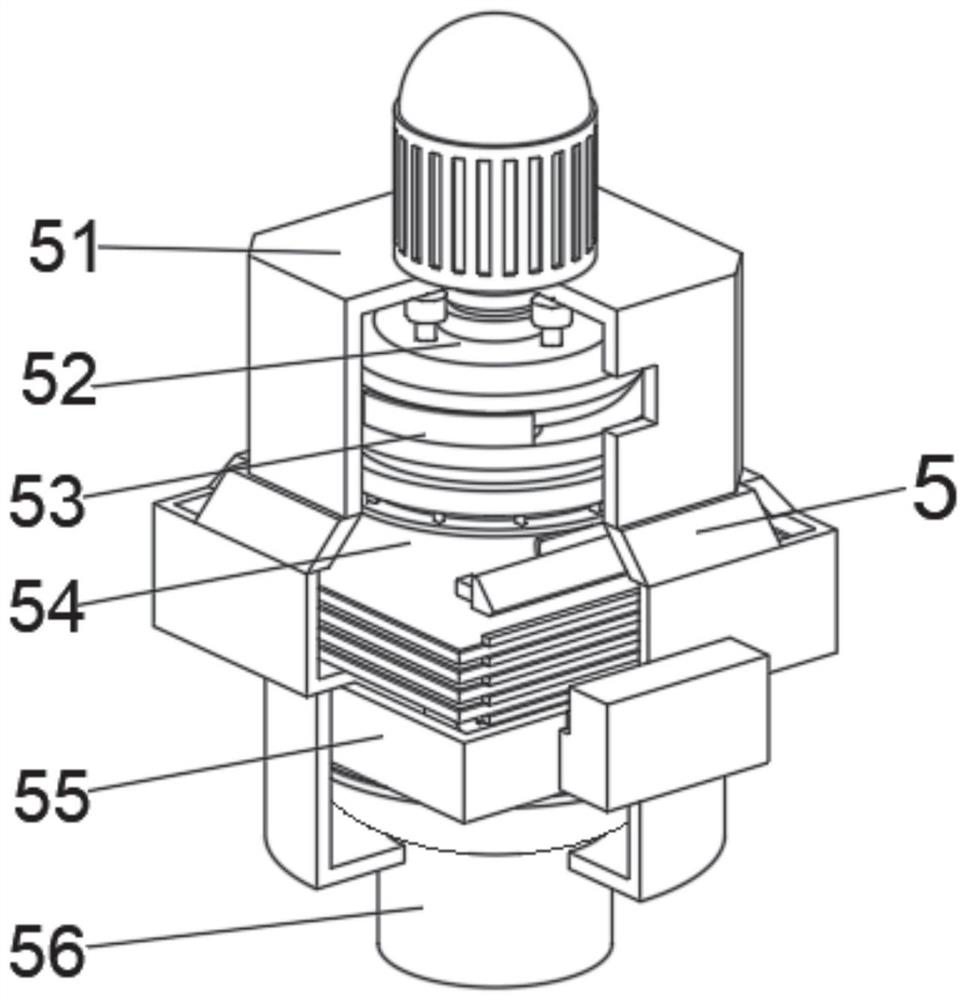

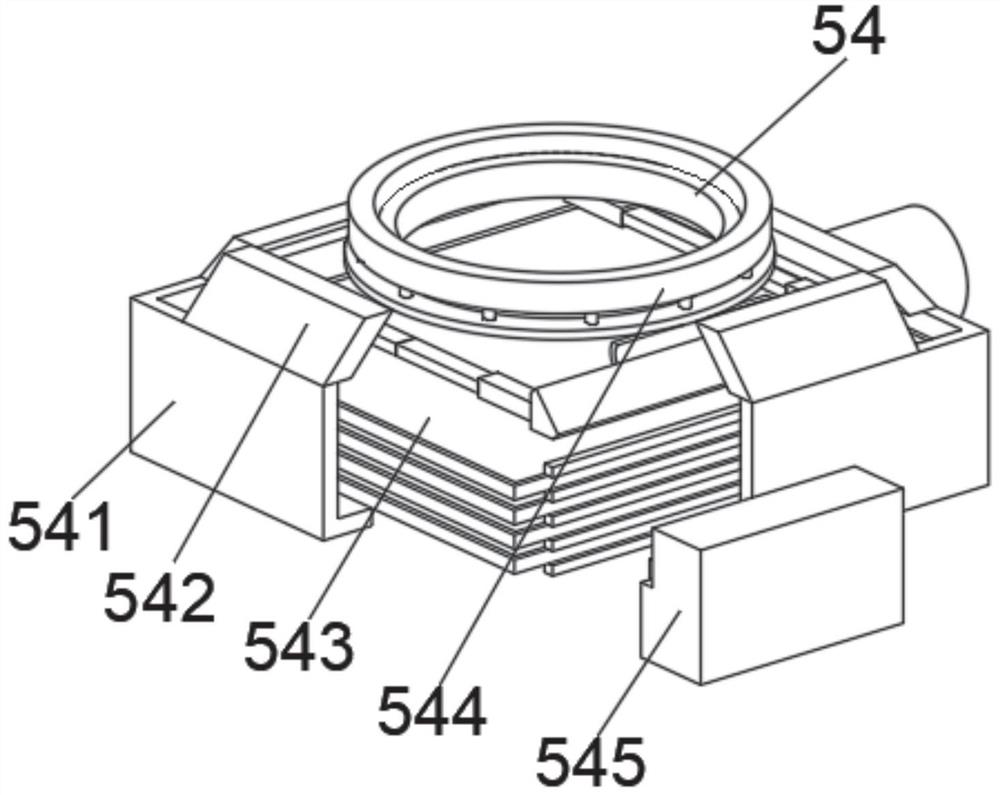

Preparation process of high-strength porous ceramic atomizing core

InactiveCN113248264AReduce manufacturing costAvoid insufficient grindingTobaccoPorous ceramicsElectric contact

The invention relates to the technical field of ceramic cores, and discloses a preparation process of a high-strength porous ceramic atomizing core, which is completed by using a grinding device for preparing the high-strength porous ceramic atomizing core. The grinding device for preparing the high-strength porous ceramic atomizing core comprises a shell, a connecting mechanism, a filtering mechanism, a rotating mechanism, a triggering mechanism, a sliding mechanism and a braking mechanism, the inner wall of the shell is movably connected with the connecting mechanism, and the inner side of the connecting mechanism is fixedly connected with the filtering mechanism. According to the preparation process of the high-strength porous ceramic atomization core, through separation of an electric contact and a conductor rail and stopping of a braking mechanism on a rotating mechanism, the phenomena that ceramic raw materials are not sufficiently ground, the particle size is not uniform after the ceramic raw materials are ground are avoided, and the situation that the hardness of the fired porous ceramic atomization core cannot reach the standard is avoided; and the qualified rate of products is increased, waste of resources is avoided, and the manufacturing cost of the porous ceramic atomizing core is reduced.

Owner:邝青

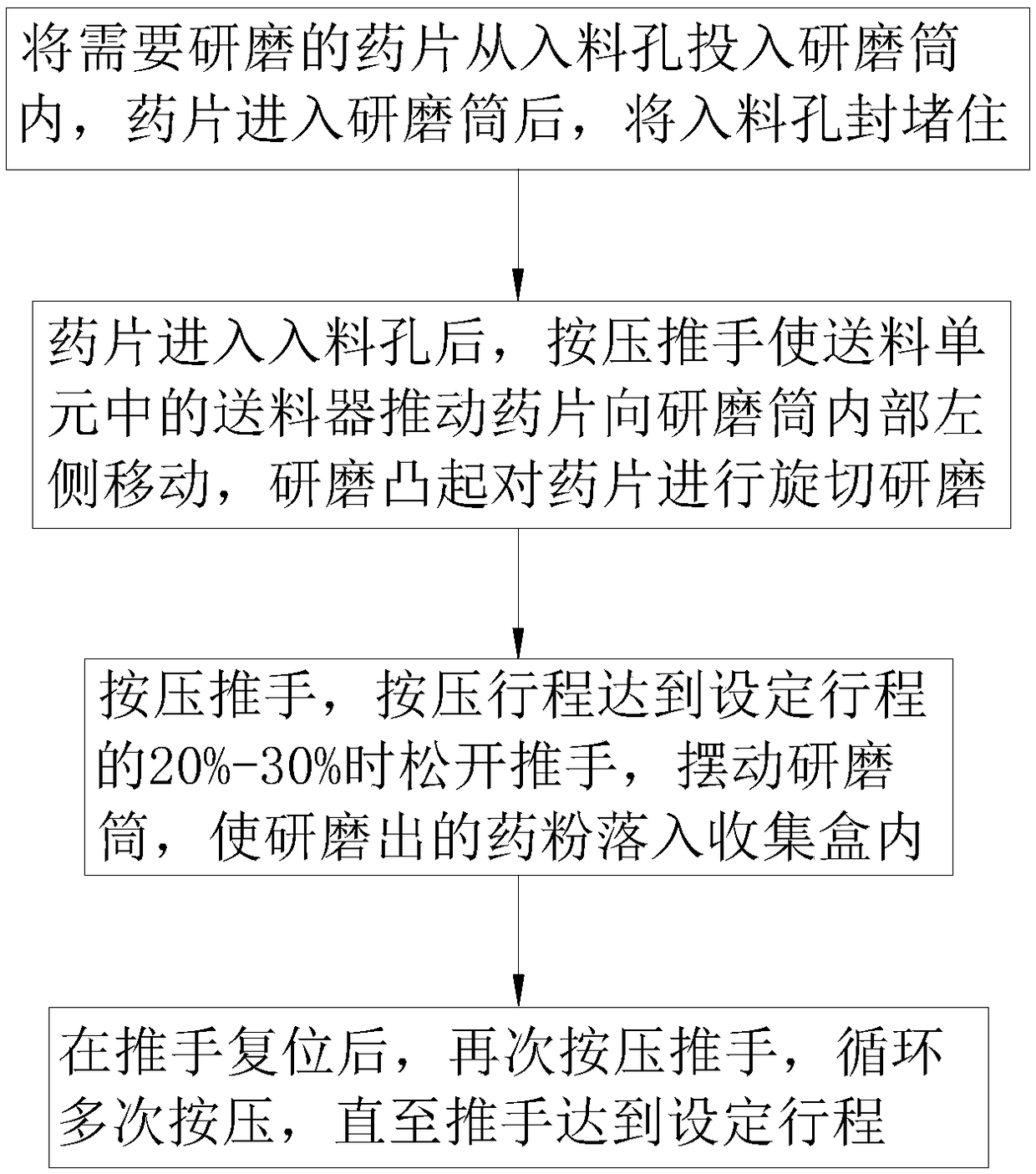

Powder medicament manufacturing method for pharmacy department

ActiveCN108578241AImprove grinding efficiencyAvoid insufficient grindingOral administration devicePharmacyEngineering

The invention belongs to the technical field of medical treatment, and particularly relates to a powder medicament manufacturing method for the pharmacy department. The powder medicament manufacturingmethod adopts grinding equipment. The grinding equipment comprises a grinding barrel, a connecting frame, a push handle and a conveying unit. The grinding barrel is in a cover-less cylinder shape. The connecting frame is vertically connected into the barrel wall of the grinding barrel. A grinding protrusion and a spiral groove are formed in the inner side barrel wall of the grinding barrel. The push handle is arranged on the right side of the exterior of the grinding barrel. The conveying unit is used for conveying tablets to the left side of the interior of the grinding barrel for grinding,the tablets are placed into the grinding barrel from a feeding hole, and then tablet raw materials are pushed to the left side of the grinding barrel through the push handle and the conveying unit. The tablet raw materials are fully crushed and ground through the grinding protrusion on the left side inner wall of the grinding barrel. Powder formed after grinding flows out from the left end of thegrinding barrel. The grinding equipment adopted by a grinding method is simple in structure and low in cost, the tablets are fully extruded and ground through the grinding protrusion and a pushing block of a material passing hole in the grinding barrel, the operation steps are simple, and the grinding efficiency is improved greatly.

Owner:淮北悯农生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com