River ecological restoration device

An ecological restoration and river technology, applied in the field of river ecology, can solve problems such as river pollution, river ecological damage, and accelerated water body aging, and achieve the effects of protecting the ecological environment, reducing the storage volume, and increasing the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

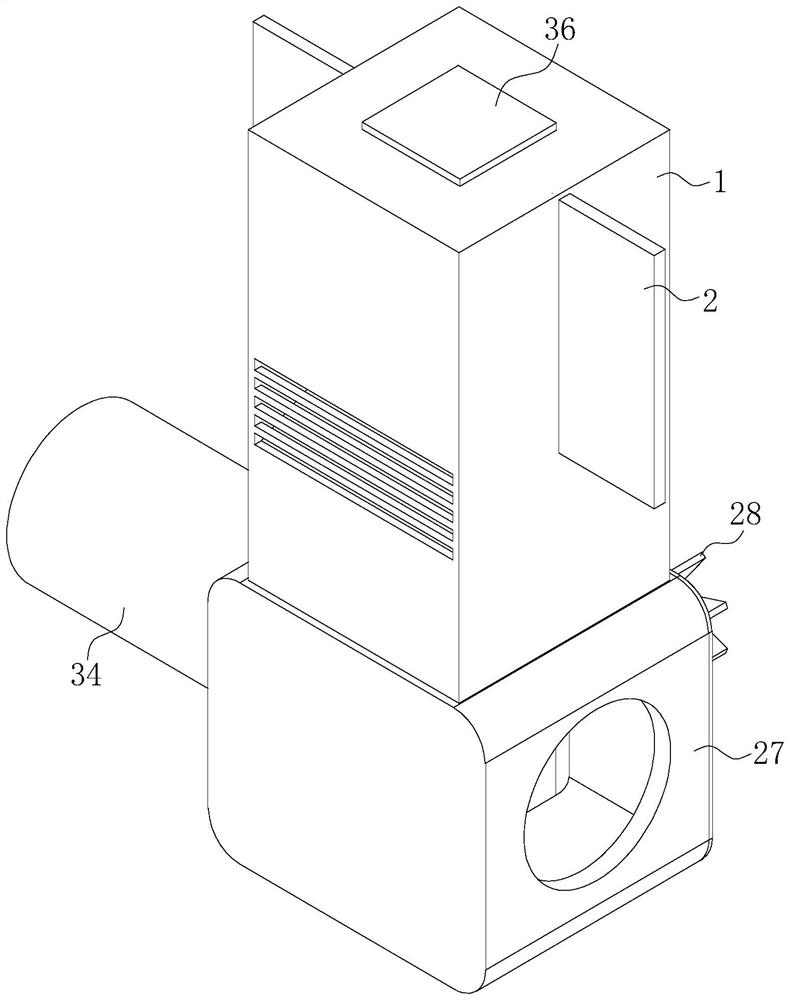

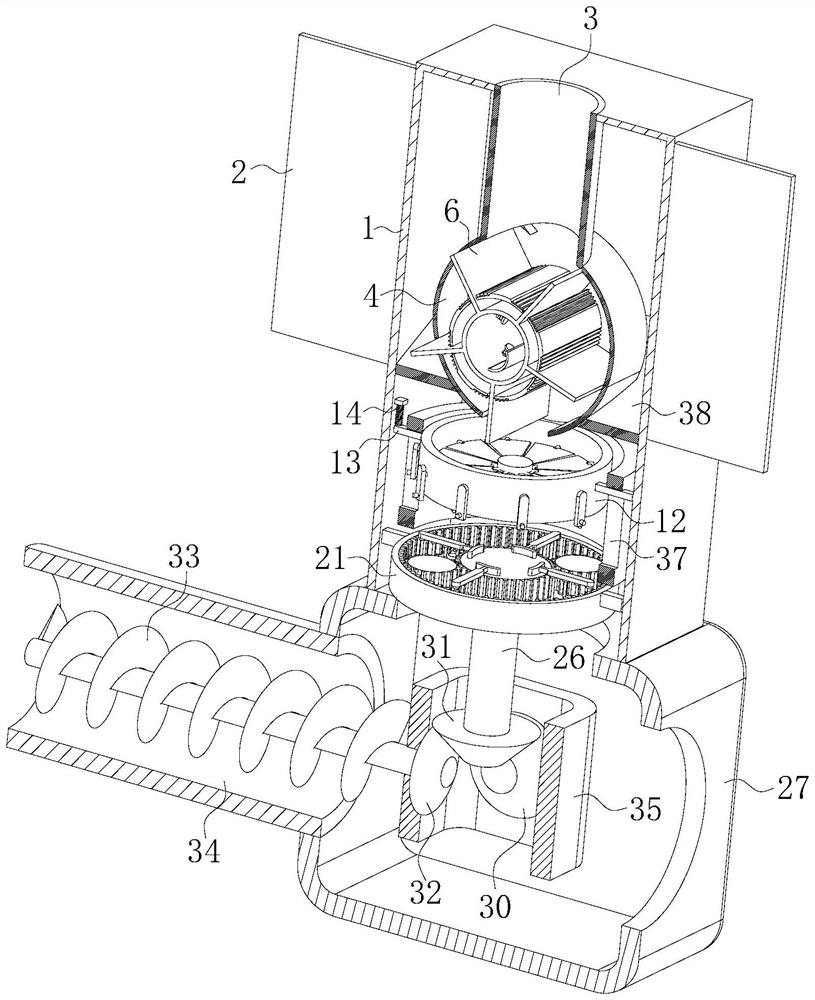

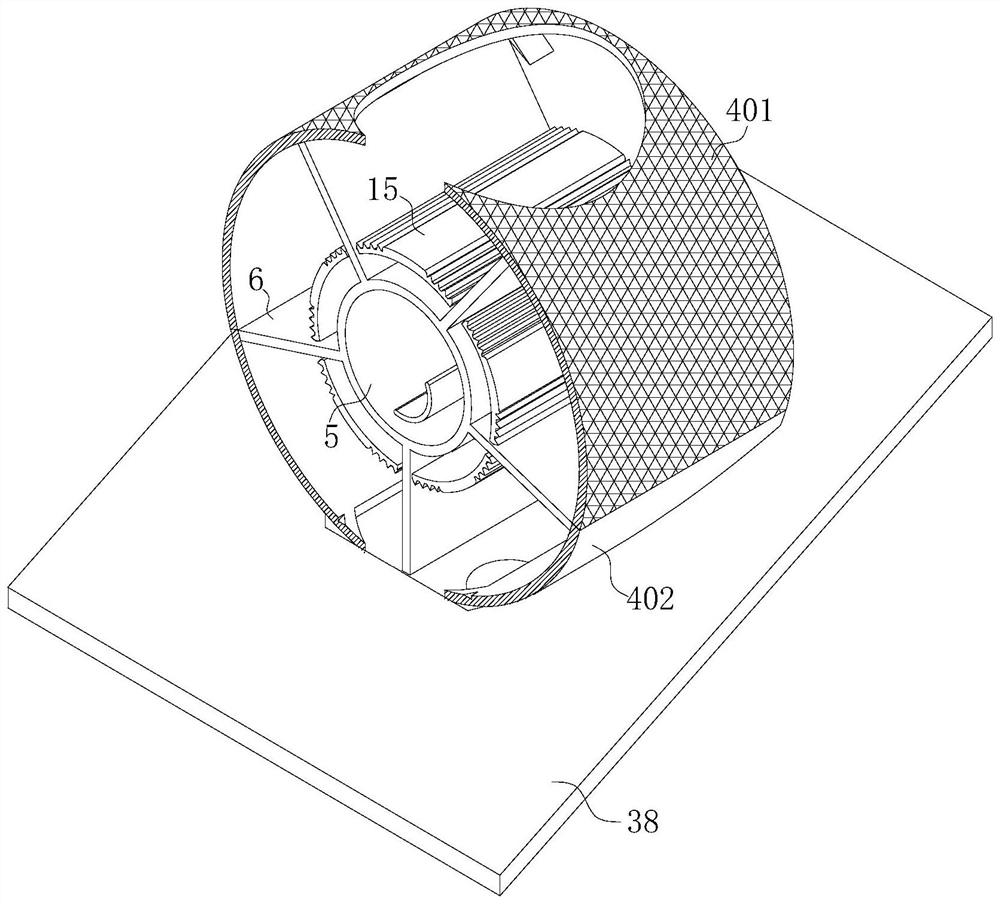

[0028] see Figure 1-10 , the present invention provides a technical solution: a river ecological restoration device, including a water inlet cylinder 1, the interior of the water inlet cylinder 1 is provided with a collection mechanism, and when the weight of the duckweed reaches a specified value, the collection mechanism first collects The duckweed on the river is collected, and then the collected duckweed is stored for the next step of processing. A crushing and removing mechanism is arranged below the collecting mechanism, and the crushing and removing mechanism firstly collects the duckweed collected by the collecting mechanism. Grinding, the pulverizing and removing mechanism automatically cleans when grinding, so that the ground duckweed can be reduced in storage volume, convenient for discharge, accelerated degradation, and convenient for the collection and processing of duckweed, and then the ground duckweed Automatically transported to shore for landfill disposal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com