Processing device for biological reagent

A processing device and biological reagent technology, applied in grain processing, dust removal, cleaning methods and utensils, etc., can solve problems such as raw material grinding that cannot produce solid reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

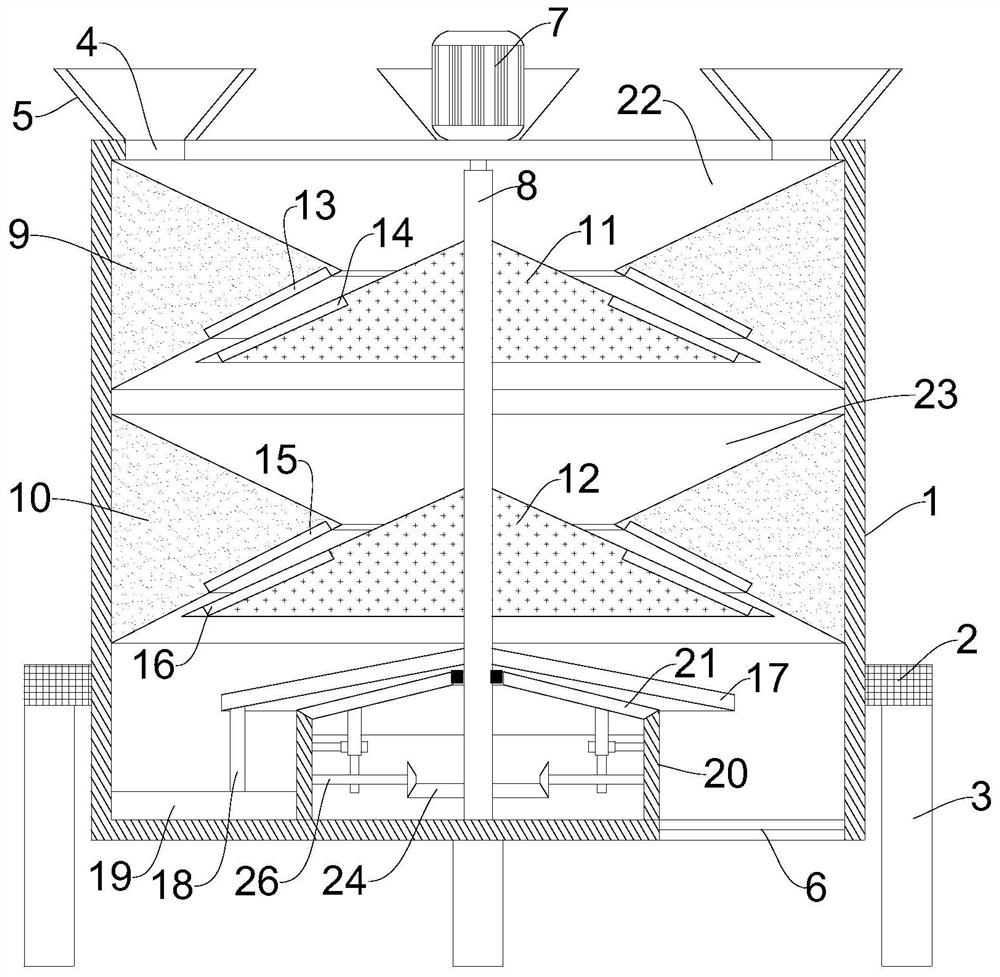

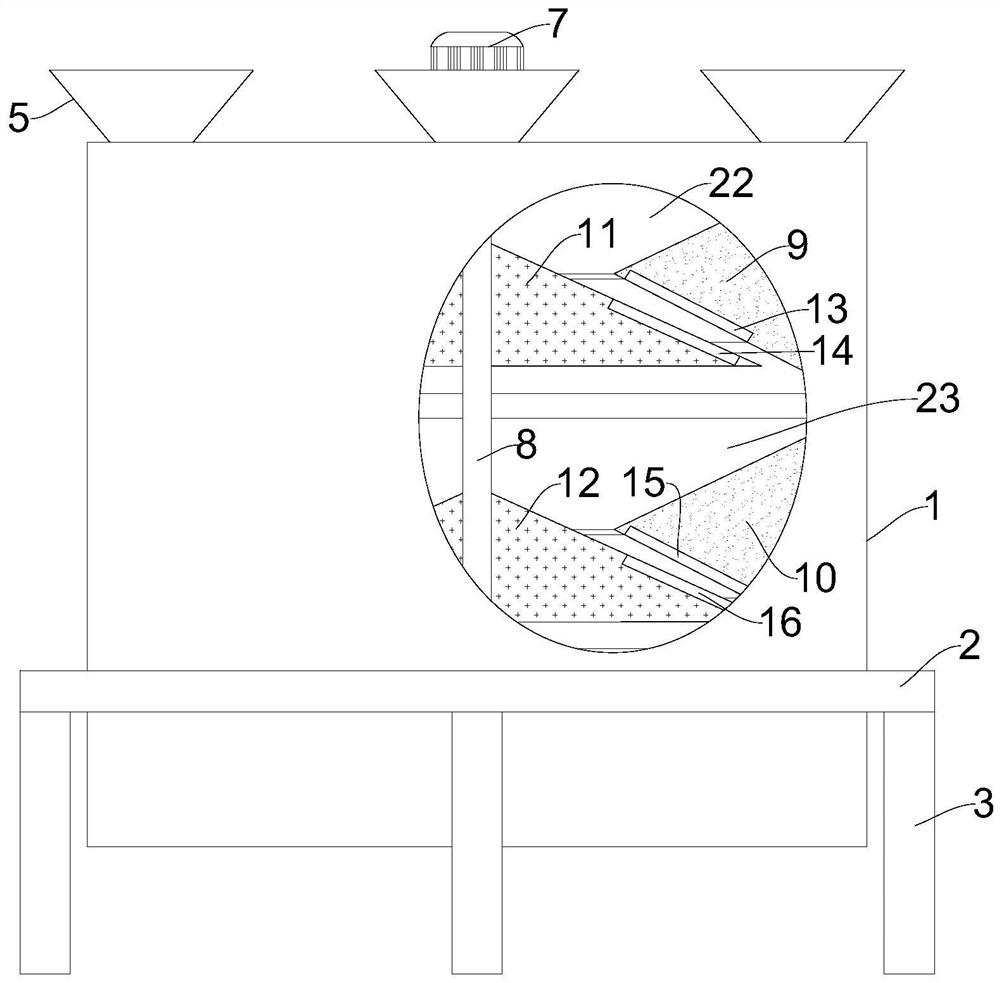

[0022] refer to Figure 1-8 , a biological reagent processing device, including a box 1, the inner coaxial center of the box 1 is respectively welded with a first fixed block 9 and a second fixed block 10, the top of the first fixed block 9 and the inside of the box 1 The top wall is in contact with each other, and the upper and lower ends of the first fixed block 9 are coaxial and symmetrically provided with a first groove 22 in the shape of a cone, and the two first grooves 22 are connected to each other, and the upper and lower ends of the second fixed block 10 are Concentric and symmetrically provided with the second groove 23 of circular frustum shape, and the two second grooves 23 communicate with each other, the radius and height of the upper and lower bottom surfaces of the first groove 22 are the same as the radius and height of the upper and lower bottom surfaces of the second groove 23. The same height, the diameter of the top of the two first grooves 22 away from e...

Embodiment 2

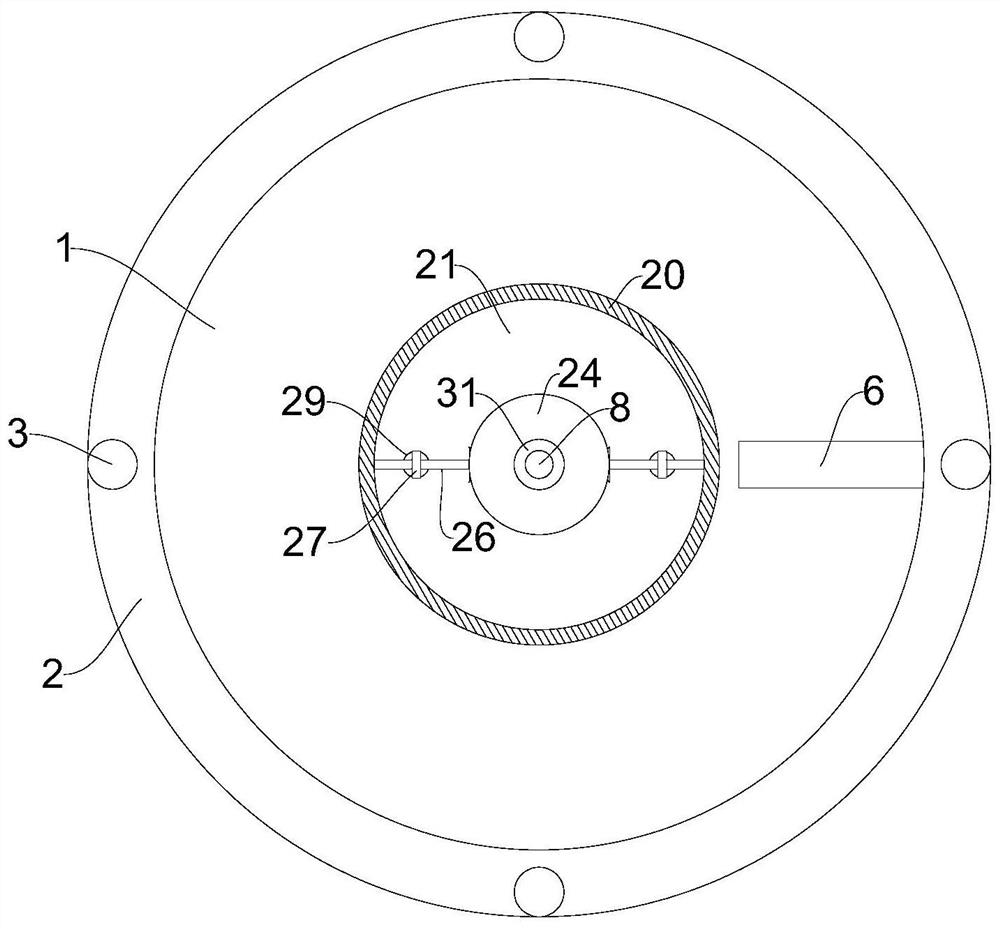

[0028] In embodiment 1, the raw material for producing solid reagents after being ground twice falls on the inner bottom wall of the box body 1. Since the area of the discharge port 6 is small, it cannot be allowed to fall on the inner bottom wall of the box body 1. All the raw materials for the production of solid reagents are discharged smoothly, refer to figure 1 , 3 and 8, as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the rotating shaft 8 below the second cone 12 is fixedly provided with a pushing mechanism, and the pushing mechanism includes a conical first shielding cover 17 , the first shielding cover 17 is coaxial and fixed on the rotating shaft 8. When the motor 7 drives the rotating shaft 8 to rotate, the first shielding cover 17 rotates with the rotation of the rotating shaft 8. The first shielding cover 17 below A fixed cylinder 20 is fixed coaxially on the inner bottom wall of the box body 1, and a connecting...

Embodiment 3

[0030] In Embodiment 2, the raw materials for producing solid reagent after being ground on the inner bottom wall of the box body 1 between the fixed cylinder 20 and the side wall of the box body 1 will cause dust due to impact, and the raised grinding The powder of the raw material for the final production of solid reagent will fall on the first shield 17, but because the rotating shaft 8 drives the first shield 17 to rotate, under the action of inertia, the rotating first shield 17 will fall on the first shield 17. The powder on the first shielding cover 17 is thrown off, so that the first shielding cover 17 is not easy to pile up the powder of the raw material for producing solid reagent after the grinding that is raised, but the powder of the raw material for producing solid reagent after the grinding that is raised will be smooth. The gap between the first shielding cover 17 and the fixed cylinder 20 falls on the inner bottom wall of the box body 1 inside the fixed cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com