Ball mill provided with filter screen

A filter screen and ball mill technology, which is applied in the field of chemical manufacturing, can solve the problems of increasing raw material loss, polluting the working environment, and increasing production costs, and achieves the effects of increasing maintenance costs, enhancing crushing effects, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

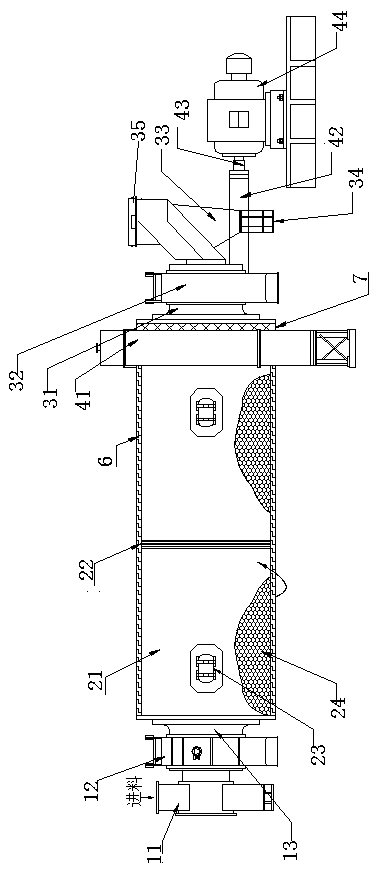

[0019] Embodiment 1: see figure 1 , a ball mill provided with a filter screen, the ball mill provided with a filter screen includes a feed assembly, a grinding assembly, a discharge assembly, a power assembly and a smoke filter assembly; the feed assembly and the discharge assembly have the powder The grinding assembly is connected and installed at both ends of the grinding assembly; the power assembly is installed on the right side of the discharge assembly, and is connected to the grinding assembly through the transmission shaft in the assembly; the smoke filter assembly is installed above the discharge assembly. It is closely connected with the filter net of the discharge assembly. The design structure is simple and clear, and the components are closely connected without interfering with each other. The required parts are easy to replace and easy to maintain during the use of the product in the future.

[0020] The feed assembly includes a feed hopper 11, a feed screw barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com