Preparation process of high-strength porous ceramic atomizing core

A porous ceramic and preparation technology, which is applied in the field of ceramic cores, can solve problems such as insufficient grinding, waste of resources, and uneven particle size, and achieve the effects of avoiding insufficient grinding, avoiding waste of resources, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

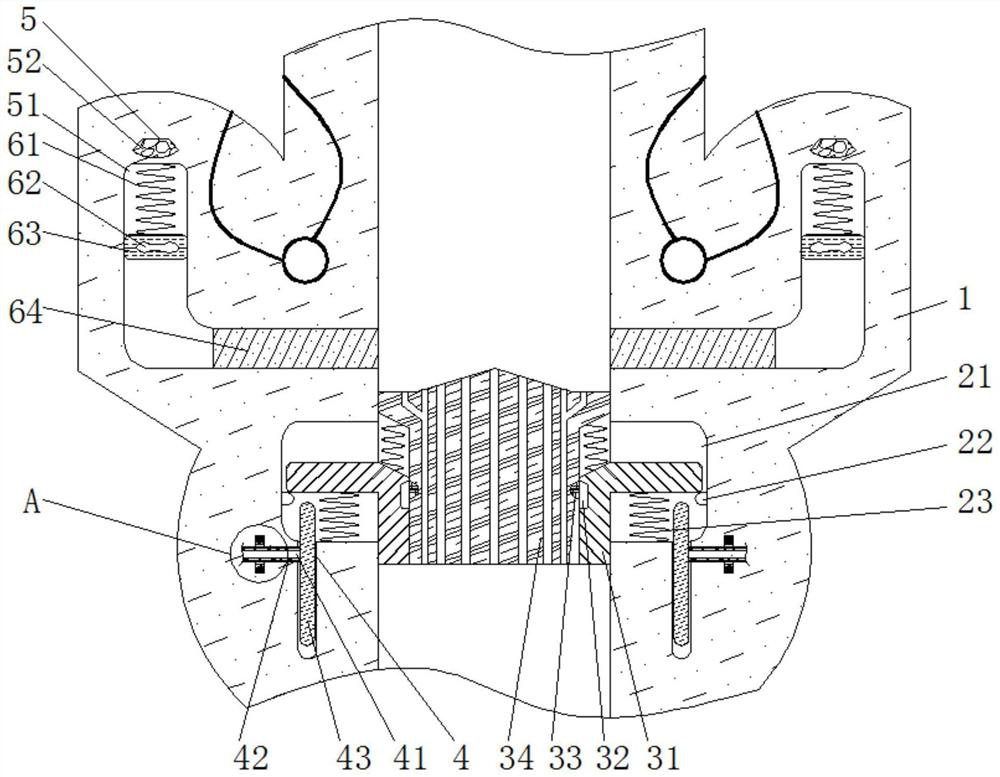

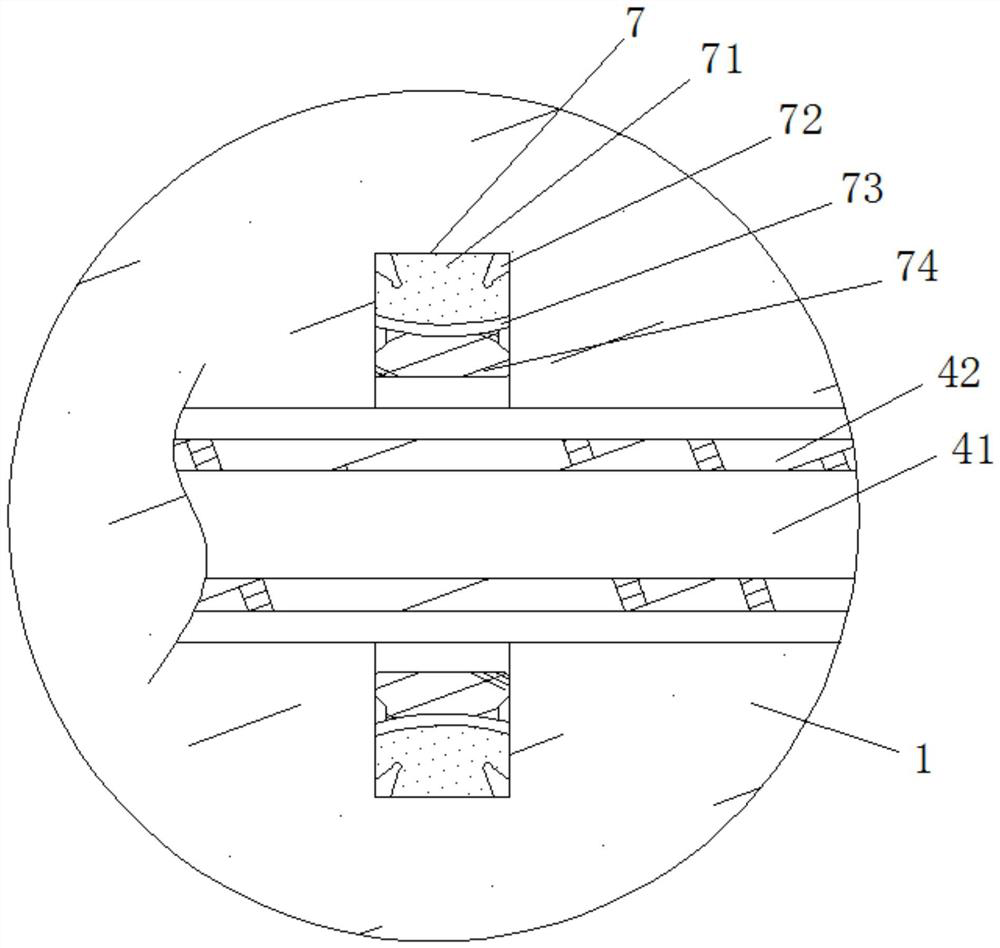

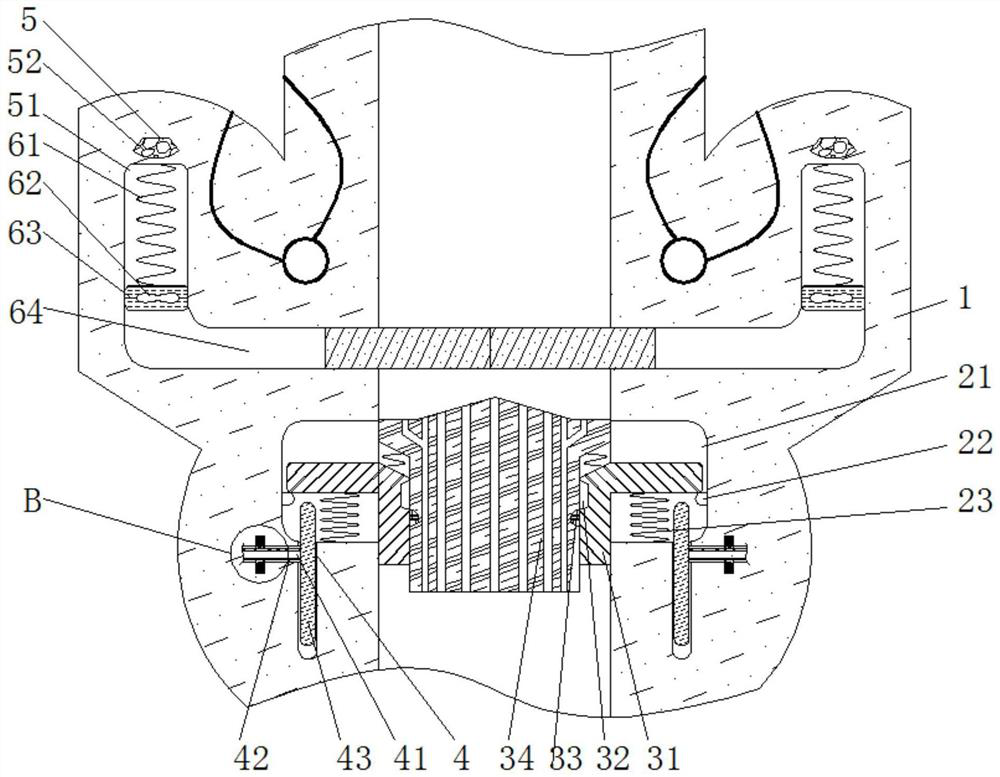

[0033] see Figure 1-4 A high-strength porous ceramic atomization core preparation process is completed using a grinding device prepared from a high-strength porous ceramic atomization core. The grinding device prepared from a high-strength porous ceramic atomization core includes a housing 1, a connecting mechanism 2, Filtering mechanism 3, rotating mechanism 4, triggering mechanism 5, sliding mechanism 6 and braking mechanism 7, the inner wall of casing 1 is movably connected with connecting mechanism 2, and connecting mechanism 2 comprises groove 21, fixed block 22 and spring one 23, and shell The inner wall of the body 1 is provided with a groove 21, the inner wall of the groove 21 is fixedly connected with a fixed block 22, the inner wall of the groove 21 is fixedly connected with a spring 23, the connecting mechanism 2 is used to connect the filter mechanism 3, and the inner side of the connecting mechanism 2 is fixed. Connected with a filter mechanism 3, the filter mech...

Embodiment 2

[0036] see Figure 1-4 , a process for preparing a high-strength porous ceramic atomizing core, comprising the following steps:

[0037] S1. Adjust the data of the grinding device and calibrate the machine several times to ensure the normal operation of the grinding device and the fineness of the grinding raw materials;

[0038] S2. Open the cover of the grinding device, evenly put the raw materials for preparing the ceramic atomizing core into the grinding device, and then close the grinding device;

[0039] S3, then connect the external power supply, adjust the data of the grinding device, and ensure the normal operation of the grinding device under manual inspection;

[0040] S4. Open the discharge port of the grinding device, place the collection container on the bottom of the discharge port, and fix the collection container;

[0041] S5. Start the grinding device, and then the ground raw materials will pass through the filtering action of the filtering mechanism 3 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com