Novel grinding apparatus

A grinding device and a new type of technology, applied in beverage preparation devices, kitchen utensils, household utensils, etc., can solve the problems of slow discharge, too large, and inability to discharge completely, and achieve the effect of preventing insufficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

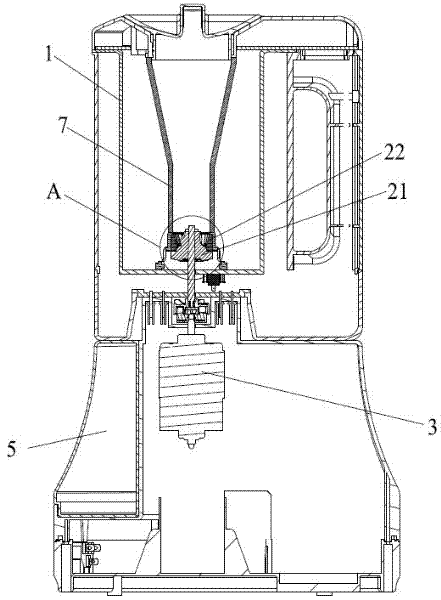

[0029] Such as figure 1 As shown, it is a schematic structural diagram of the grinding device of the present invention, including a container 1 and a base 5, a movable grinding wheel 21 and a static grinding wheel 22 that can rotate relatively at the bottom of the container 1, and a motor 3 is housed in the base 5. The moving grinding wheel 21 is connected to the motor 3 through a drive shaft 4 passing through its center, a rotation gap is provided between the moving grinding wheel 21 and the static grinding wheel 22, and the opposite faces of the moving grinding wheel 21 and the static grinding wheel 22 are provided with matching cutting edges.

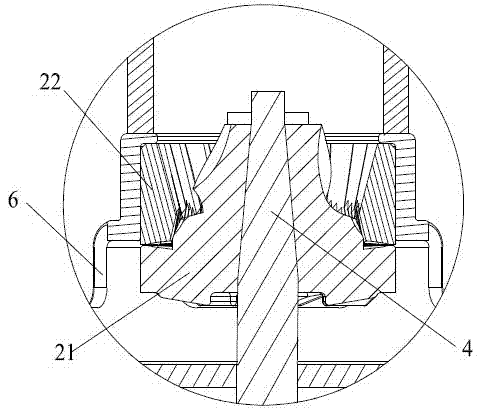

[0030] The moving grinding wheel 21 and the driving shaft 4 are in a sliding connection, and the connection between the driving shaft 4 and the moving grinding wheel 21 is a matching structure of a tapered column and a tapered hole, that is, the driving shaft 4 is in a conical structure as a whole at the connection, and the specific s...

Embodiment 2

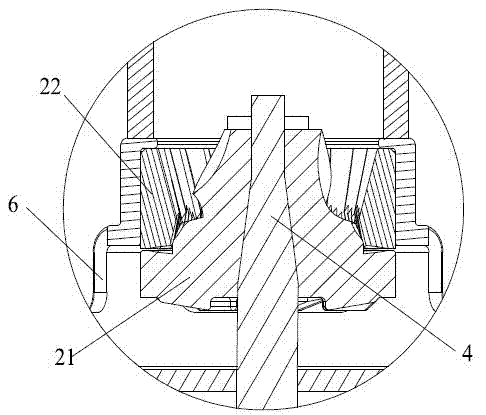

[0035] This embodiment is similar in structure to Embodiment 1, as Figure 7 and Figure 8 As shown, the difference is only that the movable grinding wheel 21 and the static grinding wheel 22 are matched up and down, the movable grinding wheel 21 and the static grinding wheel 22 are disc-shaped, the movable grinding wheel 21 is placed under the static grinding wheel 22, and the middle part of the static grinding wheel 22 is provided with a feeding port. 21 and static grinding 22 gap openings on the outside of the wheel are discharge openings. The rotation gap between the movable grinding wheel 21 and the static grinding wheel 22 gradually becomes smaller from the feed inlet to the discharge outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com