Multi-stage high-speed grain grinding device

A high-speed grinding and grinding device technology, applied in the field of grain grinding, can solve the problems of impurities falling, intermittent, reducing the quality of grain grinding, and achieve the effect of accelerating the falling, increasing the stability and increasing the grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] Example 1:

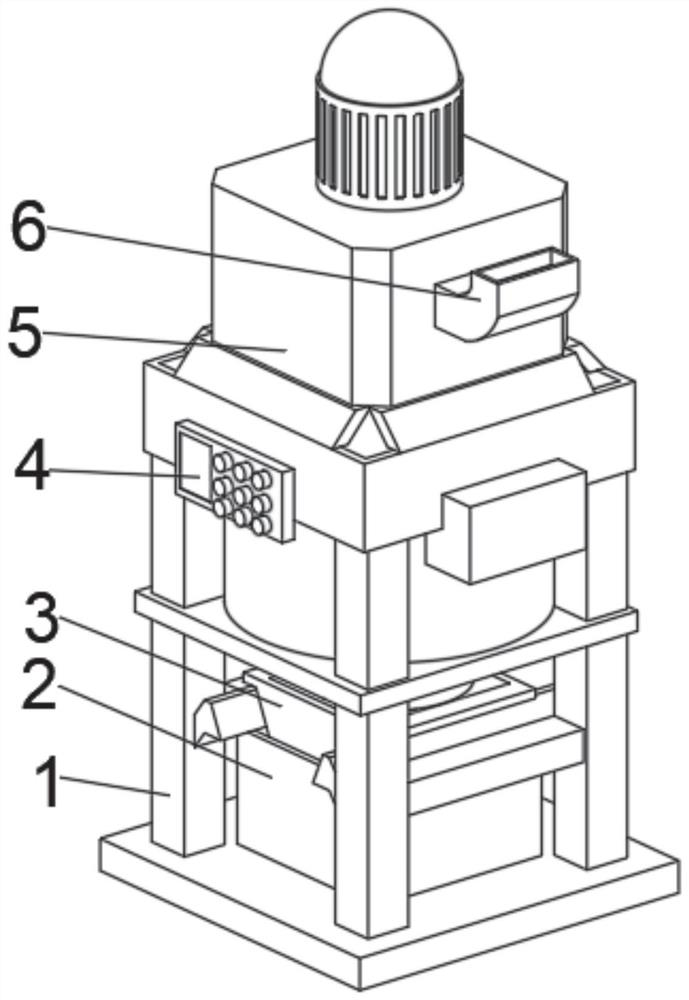

[0041] see Figure 1-6 , the present invention provides a technical solution: a multi-stage high-speed grinding device for grains, including a frame 1, through which the frame 1 is in close contact with the grinding device 5, so as to ensure the stability of the grinding device 5 during operation, so that the grinding device 5 grinds It is not easy to generate excessive shaking, and the rack 1 can be placed horizontally with the ground, thereby improving the balance of the rack 1 after being placed, preventing the rack 1 from tilting or shifting due to shaking during operation, thereby improving the performance of the rack 1. The grain collection is stable. The storage box 2 is slidably connected to the middle position of the bottom of the inner cavity of the rack 1, and the lower hopper 3 is slidably connected to both sides of the top of the storage box 2. The discharge end of the lower hopper 3 faces the storage box 2. , so that when the grain falls, it ...

Example Embodiment

[0047] Embodiment 2:

[0048] see Figure 1-6 , On the basis of Embodiment 1, the present invention provides a technical solution: a method for using a multi-stage high-speed grinding device for grains, step 1: install the equipment, and slide the storage box 2 with the lower hopper 3 , connect the grinding device 5 with the energy source, and use the feeding hopper 6 to transport the grains to the interior of the grinding device 5;

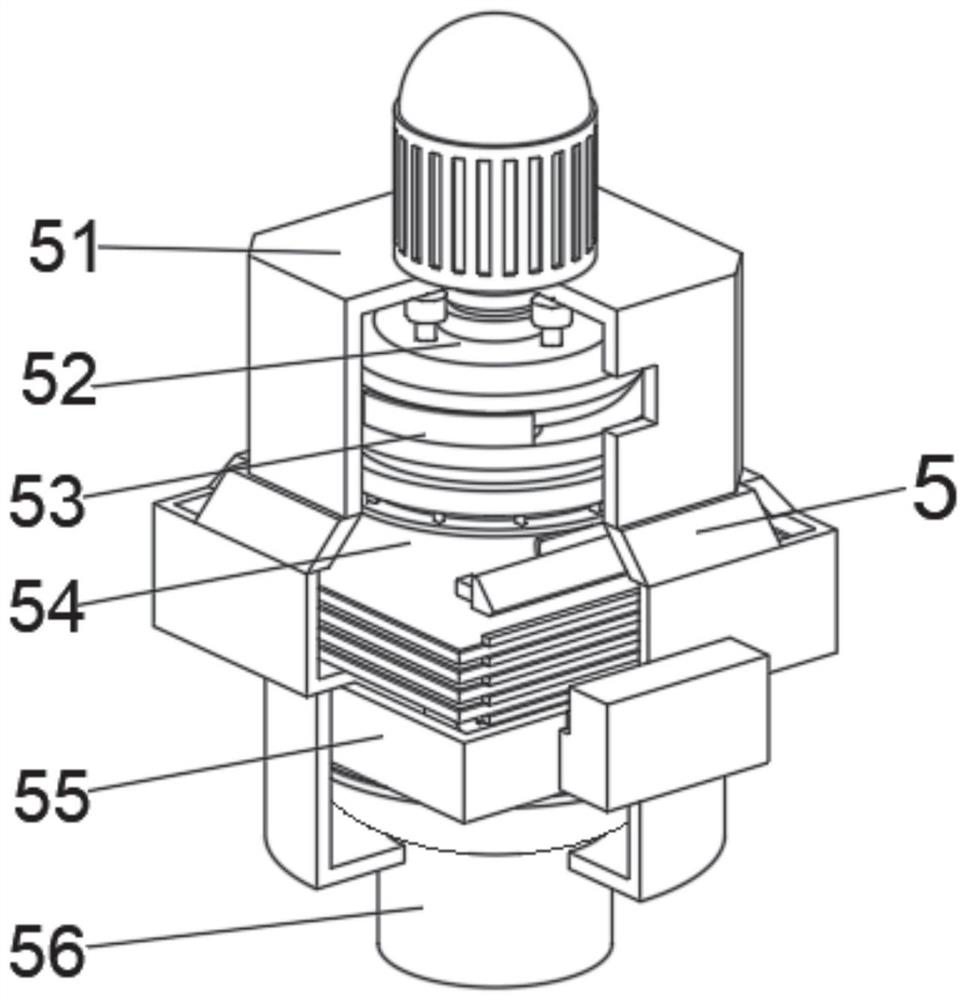

[0049] Step 2: Grinding the grains through the grinding chamber generated by the grinder 52 and the grinding assembly box 53, and as the ground grains fall into the screening device 54 for screening, the screening device 54 is fixedly connected to the protective housing 51, And the fine grinding device 55 is communicated with the guide cylinder 56, so that the grains after secondary grinding are collected through the guide cylinder 56;

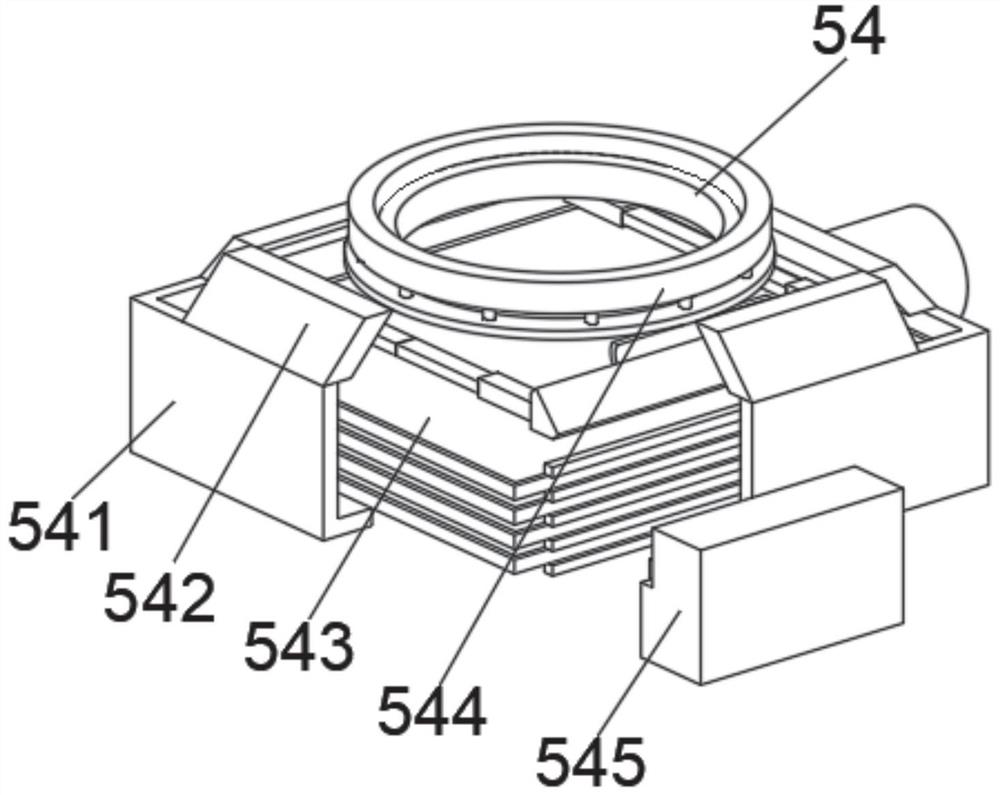

[0050] Step 3: The shaker 545 is used to drive the screening plate 543 to vibrate, so that the grains collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com