A small amount of metallic tissue grinding device

A grinding device, metal technology, applied in the direction of measuring devices, sampling, instruments, etc., can solve the problems of grinding, temperature rise, insufficient grinding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

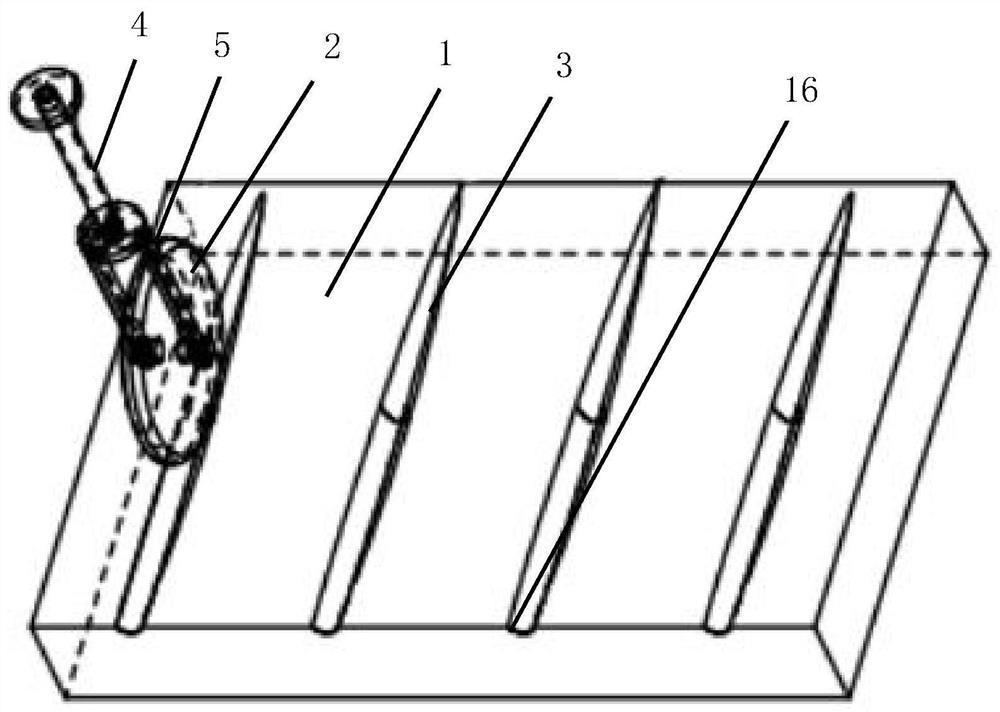

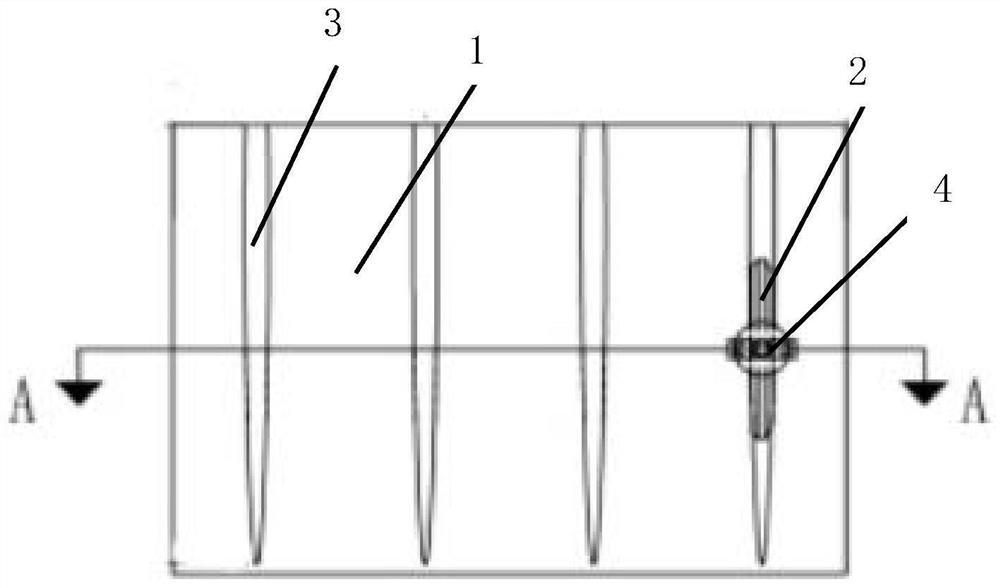

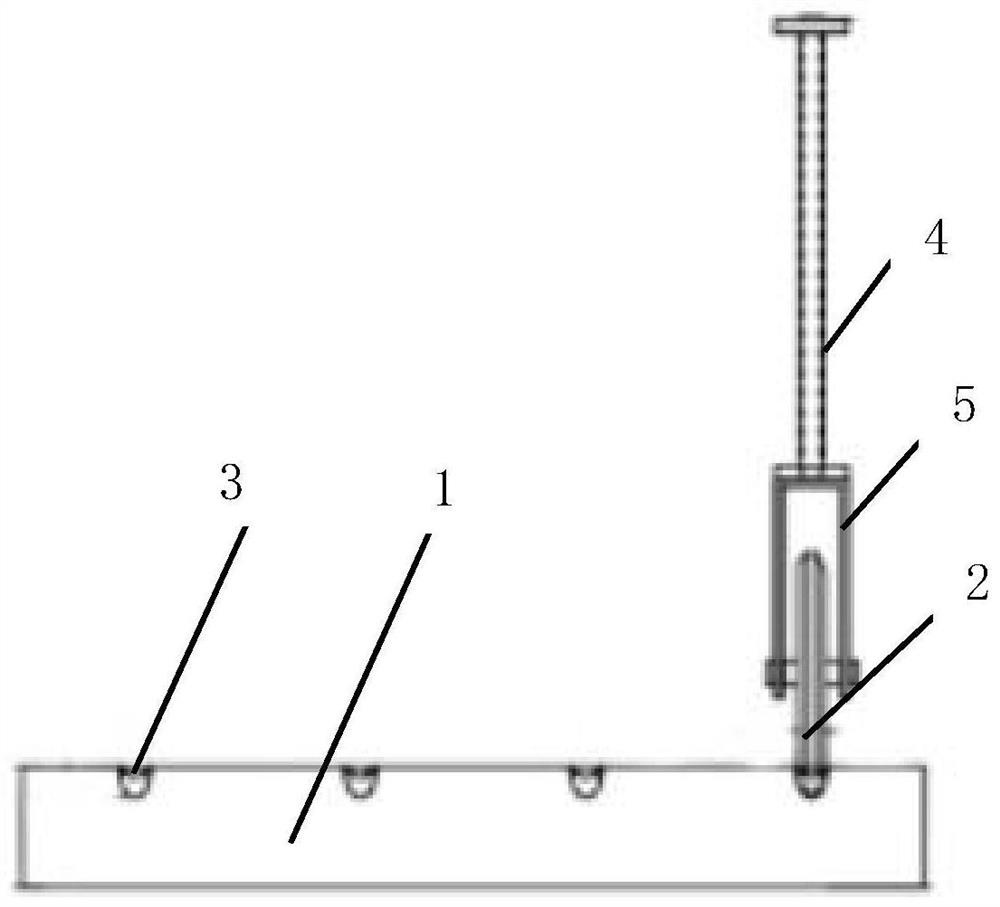

[0031] Embodiment 1: This embodiment discloses a small amount of metal tissue grinding device, including a metal block 1 and a metal grinding wheel 2 as a base, the metal block 1 is provided with a plurality of grinding grooves 3, and the grinding groove 3 In the extending direction of the length, the middle part of the depth of the grinding tank 3 is the deepest, and the two ends gradually become shallower; the metal grinding wheel 2 is provided with a handle 4, and the lower end of the handle 4 separates two metal grinding wheels 2 The branches 5 on both sides, the ends of the branches 5 are connected by a cross bar passing through the center of the metal grinding wheel 2, the metal grinding wheel 2 rotates with the cross bar as the axis, and the grinding tank 3 One end extends to the side of the metal block 1 and forms a discharge port 16 . In another more preferred embodiment, the side of the metal block 1 is provided with a protruding extension at the position correspondi...

Embodiment 2

[0036] Embodiment 2: This embodiment discloses a small amount of metal tissue grinding device, including a metal block 1 and a metal grinding wheel 2 as a base, the metal block 1 is provided with a plurality of grinding grooves 3, and the grinding groove 3 In the extending direction of the length, the middle part of the depth of the grinding tank 3 is the deepest, and the two ends gradually become shallower; the metal grinding wheel 2 is provided with a handle 4, and the lower end of the handle 4 separates two metal grinding wheels 2 The branches 5 on both sides, the ends of the branches 5 are connected by a cross bar passing through the center of the metal grinding wheel 2, the metal grinding wheel 2 rotates with the cross bar as the axis, and the grinding tank 3 One end extends to the side of the metal block 1 and forms a discharge opening 16, and the side of the metal block 1 is provided with a protruding extension at the corresponding position of the discharge opening 16, a...

Embodiment 3

[0039] Embodiment 3: This embodiment is basically the same as Embodiment 2, the difference is that it also includes a slant frame 9, and the slant frame 9 includes a slant platform 10, a plurality of supporting feet 11 arranged under the slant platform 10 and connecting The connection bar 12 of two adjacent supporting legs 11. The inclined table 10 has a certain inclination, and has a certain height through a plurality of supporting feet 11, which is convenient for the operator to exert force for grinding. The metal block 1 has a certain inclination. After the grinding is completed, the grinding tank 3 with a certain inclination makes it easier to scrape out the ground sample with a spatula and transfer it to the centrifuge tube.

[0040] Moreover, in order to better fix the metal block 1 on the inclined platform 10, the inclined platform 10 is provided with a sinking groove 13, the shape of the sinking groove 13 is adapted to the shape of the metal block 1, and the The depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com